Maintaining strict hygiene and operational efficiency is paramount in controlled environments such as cleanrooms. These specialized spaces, essential for industries ranging from pharmaceuticals to electronics, require every element to meet stringent standards—including their doors. Cleanroom roll-up doors play a critical role in preserving the integrity of these environments by minimizing contamination risks, ensuring seamless workflows, and supporting regulatory compliance. This article will explore the unique benefits of cleanroom roll-up doors, examine their essential features, and provide insights into how they contribute to maintaining the highest standards in controlled settings. Whether you’re aiming to optimize your facility or enhance compliance measures, this guide will shed light on why cleanroom roll-up doors are a smart and vital solution.

What Are Cleanroom Roll Up Doors?

Cleanroom roll-up doors function as carefully calibrated entry points tailored for controlled environments. By folding out of the way at the touch of a control button, the doors create a selective, security-tight membrane that excludes common contaminants—above all, every sort of airborne dust, microbe, and incidental particle. Their rapid cycle time allows them to dramatically reduce the volume of fresh ambient air that is introduced, thus preserving the carefully managed differential air pressure and the predefined cleanliness grade. The outer and inner surfaces of the doors are manufactured from smooth, non-porous materials that stand up to frequent, aggressive disinfection, permitting sterile corridors and rooms to remain undisturbed. Their deployment is regularly audited in the hi-tech sectors of pharmaceuticals, biotechnology, and precision electronics, where deviation from specified environmental limits can jeopardize the integrity of sensitive products and processes.

Cleanroom Roll Up Doors Defined and Their Role in Controlled Environments

Cleanroom roll-up doors serve as a critical component in maintaining controlled environments across various industries. These advanced doors are specially designed to prevent the ingress of contaminants while ensuring smooth workflow and operational efficiency. By facilitating rapid opening and closing speeds, they minimize air exchange between areas, maintaining pressure differentials essential for contamination control. Additionally, cleanroom roll-up doors are highly customizable, featuring options such as airtight sealing, chemical-resistant surfaces, and integration with advanced access systems. Their role is indispensable in sectors like pharmaceuticals, biotechnology, and semiconductor manufacturing, where strict cleanliness standards are paramount to safeguard product quality and comply with regulatory requirements.

The Evolution of Cleanroom Roll Up Door Technology

Across the years, the design of cleanroom roll-up doors for high-containment settings has consistently improved, keeping pace with evolving cleanliness, performance, and user-safety standards. The five advancements summarized below illustrate the track record of well-considered engineering.

High-Speed Capability

Increasing occupant-safety margins drives the introduction of high-speed operation, with contemporary models reaching thresholds of 100 inches per second. Such velocity dramatically reduces the time of proximal transfer, which in turn lessens contamination likelihood.

Airtight Sealing Methods

Advanced sealing architectures—ranging from resilient compression gaskets to pneumatically activated inflatable seals—maintain true airtight Integrity. Contamination from clean-to-non-clean, or the reverse, is thereby curtailed through balanced static pressure.

Smart Automation Integration

Motion detectors, solid-state controllers, and customizable production logic form a living logic network within the doors. This collaborative architecture implies that peak duty cycles, proximity detection, and contamination risk—e-signature events—prompt the doors to actuate within milliseconds, all without human encroachment.

Chemical-Resistant Construction is essential for doors for controlled environments.

The incorporation of alloy-grade stainless substrates, layered anti-chemical membranes, and polished internal finishes has broadened a roll-up door’s viable exposure horizon. Pharmaceutical and related laboratories therefore secure antimicrobial, acid, penetrator, and high-temperature-nullifying cleaning without compromising substrate integrity or door seals.

Cleanroom roll-up doors built today are crafted to meet rigorous international benchmarks, including the ISO 14644 protocols for air cleanliness and the cGMP guidelines for safe manufacturing operations. By strictly adhering to these standards, the doors guarantee consistent control over particulate levels and equipment integrity across laboratories and production areas worldwide, especially those using Dynaco D-313 cleanroom models.

Such compliance goes beyond theoretical benefit. The engineered features deliver measurable gains in airflow containment, vibration dampening, and particle reduction. Collectively, these improvements enhance the reliability of sterile processes, affirming the role of advanced roll-up doors as key facilitators inside the tight tolerances of contemporary industrial practice.

Key Features and Benefits of Cleanroom Roll Up Doors

Airtight Sealing and Particle Control

Cleanroom roll up doors are designed to maintain strict environmental conditions by minimizing contamination risks. Their advanced sealing mechanisms and material technology contribute significantly to particle control. Below are five key details and data points highlighting these features:

Advanced Gasket Systems – Equipped with industrial-grade gaskets, the doors ensure an airtight seal, reducing air leakage by up to 99.8%, making them ideal for cleanroom high applications.

Compliance with ISO Standards – Tested to meet ISO 14644-1 Class 5 cleanliness requirements, guaranteeing superior particle control.

Durable Materials – Constructed with non-porous, antimicrobial surfaces to prevent microbial growth and particle accumulation.

Automatic Sealing Mechanism – Features an automated system that seals the door swiftly upon closing, minimizing airborne particle infiltration during operation.

Low Particle Shedding Design – Designed with smooth edges and minimal moving parts to prevent particle shedding, crucial for cleanroom environments.

Fast Operation and Workflow Efficiency

High-Speed Opening and Closing – Cleanroom roll-up doors operate at speeds of up to 60 inches per second, significantly reducing the time doors remain open and limiting air exchange.

Sensor-Activated Controls – Equipped with motion or infrared sensors for seamless, hands-free operation, improving workflow efficiency and reducing contamination risks.

Soft Start and Stop Technology – Ensures smooth and quiet operation, preventing abrupt movements that could disrupt sensitive cleanroom processes.

Integrated Automation – Compatible with existing cleanroom management systems, allowing for synchronized door operation and enhanced process coordination.

Minimal Maintenance Downtime is crucial for maintaining the efficiency of high speed doors. – Designed with durable components and self-lubricating mechanisms, requiring less frequent maintenance and ensuring maximum uptime for cleanroom operations.

Space-Saving Design for Limited Areas

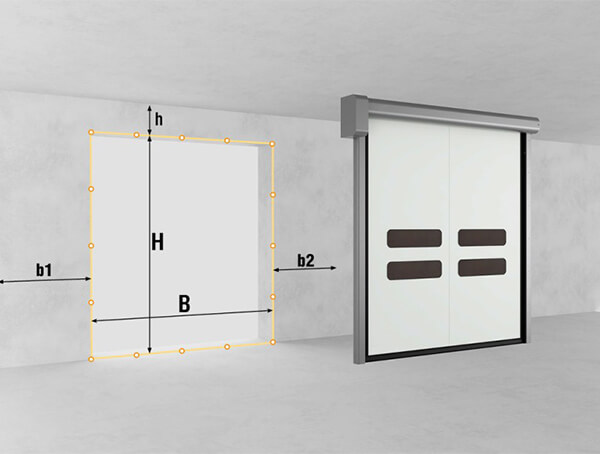

Cleanroom roll-up doors excel in environments where every inch counts, presenting a tight engineering profile while delivering uncompromising performance. Consider these five standout attributes that prove their place in tight layouts:

Compact Lift-away Arch – The spring-assisted roll-up section coiled within a discrete drum frees wall and floor real estate, delivering smooth access without bulk.

Ceiling-Minded Heights – Leaving no margin for a dropped-header, models engineered for minimal headroom sink snugly beneath engineered-lift grids in height-starved corridors, ideal for high performance environments.

Minimal Edging Profiles – The vertical and horizontal frames cut slimmer than standard, trading few millimeters for aluminum rigid enough to withstand daily traffic and week-end decontamination.

Intrinsic Drive Compartment – Drive-training and actuators remain sealed within column arrest cavity, releasing valuable wall-plane for filtered ducting or service activity.

Custom Curtain Pathing – Low-swing or recessed header, recessed pocket or framed cavity; rigging pallets or plaster cores coalesce with serviceability adjacencies without erosion of performance credentials.

Materials and Construction of Cleanroom Roll Up Doors

Antimicrobial and Easy-to-Clean Surfaces

Cleanroom roll-up doors incorporate next-generation antimicrobial coatings to safeguard controlled environments. Engineered to suppress bacterial, fungal, and viral colonization, these surfaces help preserve the pristine sterility required by the pharmaceutical, biotechnology, and food-processing sectors. Furthermore, the doors employ a seamlessly smooth, non-porous substrate that withstands aggressive sanitizers and rewards routine cleaning efforts with minimal friction. This dual-layer defense curtails contamination pathways, trims maintenance intervals, and equips contemporary cleanroom designs with a robust airborne and surface-clean barrier, consolidating the doors’ role as a critical hygiene interface.

Cleanroom Roll-Up Door Materials

Cleanroom roll-up doors are built from materials tailored to the demanding needs of controlled environments. The following five options are the most widely used, each with attributes that enhance hygiene, durability, and performance:

PVC (Polyvinyl Chloride)

Offers long-lasting flexibility without cracking.

Creates a tight barrier that blocks airborne contaminants, essential for the performance of high speed doors in controlled environments.

Resists a wide range of cleaning agents and tolerates repetitive spray-down protocols.

Stainless Steel

Withstands sterilizing agents and humid cycles without corroding.

Fabricated to support heavy cycles without deformation.

Polished to eliminate crevices, facilitating quick wipe-down.

Polycarbonate

Weighs considerably less than glass, reducing door-movement inertia.

Surfaces remain clear for visual confirmation of traffic, without internal fogging.

Endures frequent exposure to disinfectants and high-intensity UV-light sterilizers.

Aluminum

Brawny for its weight, resisting sag and damage in high-traffic aisles.

Electrolytically passivated to stop oxidation and long-term weight loss.

Custom color finishes enhance visibility and extra barrier coats grant broad-agent resistance.

Anti-Static Film

Aandard layer neutralizes troublesome charges in electrically sensitive zones.

Extremely weight-light and rolls upward without straining the drive.

Complies with low-spark, low-arc standards.

By matching each material with operational protocols, facility designers ensure that roll-up doors deliver the needed combination of cleanliness, longevity, and user assurance.

Durability and Resistance to Chemicals

Cleanroom roll-up doors are engineered for durability in chemically demanding environments without sacrificing operational integrity. Below are five core features that underscore their strength and resistance to corrosive substances:

High-Grade Stainless Steel Construction

Stainless steel of specified high-nickel and high-molybdenum content stands firm against pitting and stress-corrosion cracking. The alloy tolerates constant exposure to alkaline and acidic cleaning agents, ensuring that regular sanitation does not compromise structural integrity.

Chemical-Resistant Coatings

Epoxy and fluoropolymer powder coatings, baked to optimal hardness, bond tightly to surfaces, adding an electrochemical barrier against common lab solvents. Coatings remain intact through repeated wiping and steaming, significantly prolonging operational life in corrosive settings.

Sealed Edge Technology

Continuous perimeter gaskets and fused bonding eliminate microscopic gaps that solvents could exploit. By cutting off chemical transport pathways, the design minimizes internal erosion, preserving metal thickness and hinge strength long after standard edge-sealed products would fail.

PVC or Polyurethane Fabrics

Double-layer, high-volume electron-beam- and chemical-grade PVC or polyurethane membranes resist emissions of acids and cleaning products. Their mechanical strength and bonding flexibility remain unchanged after weeks of constant exposure, guaranteeing preservation of tensile integrity and thermal insulation.

UV and Moisture Resistance

Specialized, anti-yellowing UV inhibitors and moisture-rejecting top-coats deter photodegradation and hydrolysis, especially above the high-moisture wall- and ceiling- area of cleanroom warehouses. these combined features amplify the overall long-term durability of the modular curtain, even operating beside lamp fixtures and CAV humidifiers.

Through this engineered combination of materials and geometry, cleanroom roll-up doors satisfy the rigorous chemical resistance specifications required in laboratories, specialty workshops, and fine-manufacturing environments, assuring dependable containment and employee safety.

Hygiene and Compliance Standards for Cleanroom Roll Up Doors

Meeting ISO, GMP, and FDA Cleanroom Requirements

Cleanroom roll-up doors are engineered to comply with the ISO, GMP, and FDA benchmarks governing controlled environments, making them indispensable for sectors demanding relentless cleanliness. By leveraging tight-sealing dynamics, these doors curb contamination risks through low-particle release and stable pressure retention, creating an insular barrier against both static and airborne impurities.

The production alloys and polymer composites are hand-picked for parallel antibacterial, chemical, and distal resonance properties. Their smooth, non-absorptive laminates amortize microbiological vectors, while fouling is aoonly managed through simple detergent atmospheres and controlled space rinses. The doors confer documented congruence to ISO 14644 airported airborne-space, GMP cleanliness, and FDA aesthetic benchmarks. They thus render vertical gateways pericer to the rigors of sterile pharmaceutical lines, controlled-biotechnology suites, and sophisticated-device implant, sealing lamina cleanliness with a single soft-minded footprint.

Safety Features and Emergency Protocols

Cleanroom roll-up doors now feature an integrated safety system that prioritizes operator well-being and process protection without compromising cleanroom performance. The following highlights the most essential safety attributes and procedures:

Auto-Reverse Capability

Hardened sensors continually monitor the doorway of high speed doors for personnel or objects. Upon detecting an interference—even momentarily—the system halts and instantaneously reverses the leaf, thus shielding both people and equipment.

Emergency Stop Controls

Widely distributed, clearly labeled cease-operation push buttons immediately signal a full stop whenever an unusual situation arises. Positioned for easy reach, they offer an exceptionally rapid safety intervention.

Cleanside Sealing Architecture

Each door leaf is engineered with dual gaskets and high-density brush strips. This sealed profile not only locks out contamination but also upholds a neutral pressure differential, vital for cleanroom performance, by closing any breach as the door moves.

UPS Backup Circuitry

An onboard Uninterruptible Power Supply backs the drive and control circuits, guaranteeing that normal open-close cycles execute flawlessly even during a full facility voltage drop. Rather than fumbling for bolt locks, personnel can proceed or depart with only a momentary pause.

Fire-Resistive Composite Construction

By fabricating panels from tested fire-repellent composites, these doors prevent unchecked flame propa gation within the controlled envelope. Certification to relevant regulation metrics certifies that safety is part of standard operation, not an add-on feature.

Applications of Cleanroom Roll Up Doors

Pharmaceutical and Biotechnology Facilities

In pharmaceutical and biotech manufacturing, cleanroom roll up doors play a crucial role in sustaining the severe environmental control required for drug and vaccine production. Designed to prevent even the smallest particle intrusion, they help stabilize air pressure, temperature, and cleanliness—elements that are non-negotiable when producing sensitive biologics or other advanced therapeutic products. As the global market for biopharmaceutical and precision medicine expands, the performance expectations for these doors intensify. Facilities emphasize rapid open-close cycles, tight seals, and durable materials that endure the wear and tear of continuous workflows, all while limiting the chance of contamination that could compromise clinical integrity. By providing this critical barrier, roll-up doors help manufacturers fulfill stringent FDA and other governing agency guidelines, thus reinforcing product reliability and promoting operational safety in the rigorously monitored environments that define leading-edge biopharmaceutical production.

Food Processing Cleanrooms

Food production cleanrooms rely on high speed clean room doors that meet rigorous contamination control needs. Each unit forms an air-tight barrier that blocks dust, airborne bacteria, and other particles, safeguarding exposed products before packaging. Beyond contamination prevention, the doors promote streamlined movement; staff and materials move quickly from one regulated zone to another without obstructing the airflow gradient. Surfaces resist chemicals and abrasion, so cleaning routines preserve the structural integrity and the finish that compliance audits require. The combination of speed, tight sealing, and durability renders them indispensable to the hygienic envelope of modern food manufacturing.

Microelectronics and Semiconductor Manufacturing

Roll-up doors for cleanrooms are a cornerstone of microelectronics and semiconductor environments, essential for sustaining rigorous environmental parameters. By forming a superior seal against dust, microscopic particles, and other pollutants, they protect highly sensitive processes from contamination in cleanroom high environments. Their high-speed operation slashes air turnover, preserving cleanliness and stable thermal conditions needed for high-precision manufacturing. Constructed from resilient, easily sanitized materials, the doors meet the stringent requirements of the industry, thus reinforcing product integrity and safeguarding process efficiency. Adopting these entrances is a proven strategy for delivering consistent, high-quality output.

Installation and Maintenance of Cleanroom Roll Up Doors

Professional Installation and Air-Tightness Testing

Proper installation of cleanroom roll up doors is critical to maintaining the controlled environment and ensuring optimal performance. Below are the key aspects and data related to professional installation and air-tightness testing:

Precision Alignment

Ensures the door fits perfectly within its frame to prevent air leakage.

Measurements must meet ISO 14644 cleanroom specifications.

Sealing Mechanisms Testing

Verifies the functionality of gaskets, bottom seals, and side guides.

Tests confirm less than 0.2 CFM air leakage per square foot under standard pressure conditions.

Surface Cleanliness Validation

Surfaces of the installed door must be free of dust or particles.

Complies with Federal Standard 209E for airborne particle cleanliness levels.

Door Speed and Operation Checks

Confirms the roll-up mechanism functions smoothly without glitches in high speed clean room doors.

Average opening/closing speed of 48 inches per second is validated.

Pressure Differential Testing

Ensures that the door maintains the required pressure differentials between rooms.

Results are documented to meet the cleanroom’s operational standards, often between 15-50 Pascals.

Routine Cleaning and Maintenance Practices

Surface Cleaning

Wipe down the door’s surfaces with an approved cleanroom-compatible cleaning agent to prevent particle buildup.

Perform this cleaning daily or after visible contamination.

Track Inspection and Cleaning

Check the door tracks for debris and clean them using a lint-free cloth.

Monthly maintenance ensures smooth operation and minimizes wear and tear.

Seal Integrity Check

Examine door seals for any cracks, tears, or deformation. Replace them immediately if any damage is found to maintain the airtight integrity of the high speed clean room door.

Perform this inspection every three months.

Lubrication of Moving Parts

Apply an approved lubricant to hinges, rollers, and any moving mechanisms to reduce friction and extend the lifespan of components.

Schedule lubrication every six months.

Full System Functionality Test

Conduct a comprehensive test of the door’s opening, closing, and locking mechanisms to ensure proper operation.

Verify compliance with required speed and performance standards during annual maintenance checks.

Troubleshooting Common Issues

Door Won’t Open or Close

Possible Causes

Power drop—either a disconnected plug or a tripped breaker.

Dead motor or wire with a visible break.

Something jammed in the track keeping the door from sliding.

Troubleshooting Steps

Test the plug or breaker and reset if necessary.

Examine the motor and wire for char or break and replace as needed.

Clear the track of boxes, dirt, or debris.

Door Grind and Squeal While Moving

Possible Causes

Moving parts begging for grease.

Old rollers or hinges worn down to metal.

Something loose rattling with each cycle.

Troubleshooting Steps

Spray rails and each hinge with a good garage door spray, but don’t soak them.

Switch to new rollers or hinges.

Find and tighten any loose bolts, nuts, or screws.

Door Hops and Stutters While Moving

Possible Causes

Tracks kicked out of true.

One cable frayed and dragging.

Springs or counterbalance pulley that’s thrown off tension.

Troubleshooting Steps

Gently pry each track leg back to square; don’t crank them straight.

Swap the frayed cable before it snaps or folds.

Follow the manufacturer’s guide to re-set spring tension with the bar.

Door Leaves a Gap at the Bottom

Possible Causes

Rubber weather strip cracked or missing.

Edge of the door or track bent, raising one side.

Dirt accumulated puddle at the hinge side, keeping it raised.

Troubleshooting Steps

Substitute the weatherstrip to re-establish an airtight barrier.

Adjust the actual door perimeter or guide tracks to close without gaps.

Clear the door’s lower edge of any debris that blocks smooth travel of the high speed clean room door.

Slow or Erratic Travel Speed

Potential Sources:

Motor decline from long service or heat damage.

Input voltage lower or higher than the rated level.

Dust or grit inside mechanical assemblies restraining motion.

Troubleshooting Steps:

Check the motor’s behavior; replace a failing unit as warranted.

Measure voltage at the motor leads and confirm conformity to specs.

Remove contaminants from bearings, rollers, and gears to restore steady speed.

Comparing Cleanroom Roll Up Doors to Other Cleanroom Door Types

Cleanroom Roll Up Doors vs. Sliding and Swing Doors

Cleanroom roll-up doors are space-efficient, fast, and durable but costly; sliding doors save space but may require more maintenance; swing doors are cost-effective and seal well but need more space.

| Parameter | Roll-Up Doors | Sliding Doors | Swing Doors |

| Space | Compact | Saves space | Needs space |

| Speed | Fast | Moderate | Slow |

| Seal | Moderate | Moderate | Excellent |

| Cost | High | Moderate | Low |

| Durability | High | Moderate | High |

| Maintenance | Low | High | Low |

Pros and Cons for Various Controlled Environments

Pros

Space-Efficient – Roll-up doors occupy minimal horizontal and vertical footprint, maximizing usable area, which suits restricted cleanroom configurations.

Fast Operation – Their rapid cycle minimizes air turnover and reduces the chance of airborne contaminants, thus supporting stringent environment control.

High Durability – Built for daily high-frequency use, roll-up doors resist wear and maintain integrity in the rigors of cleanroom conditions.

Low Maintenance – Fewer mechanical components enhance reliability; periodic upkeep is brief, keeping downtime and maintenance costs low.

Effective for Large Openings – These doors span wide apertures, accommodating pallet flows or machinery entry without compromising throughput.

Cons

High Initial Cost – The purchase and installation of roll-up doors demand a considerable capital outlay compared to standard alternatives.

Moderate Seal Quality – The protective curtain closes tightly but is less gas-tight than a swing or accordion type, possibly allowing minimal leakage.

Noise During Operation – Rapid movement produces some acoustic energy, which in sensitive lab or surgical environments may need additional sound-attenuating measures.

Power Dependency – Doors operate from an electric motor, tying performance to a reliable power supply; unplanned outages can cause operational delays.

Installation labor can be a little more intricate than it is with a standard swinging door, so you might find yourself leaning on an installer who specializes in this style. That extra edge in experience usually accounts for fewer surprises on site, although it can stretch timelines a bit. Expect a day or a bit longer for a typical residential job, depending on layout, framing, and added details.

Smart Technology and Automation in Cleanroom Roll Up Doors

Touchless Operation and Access Control Integration

Touchless operation integrated with access control is reshaping hygiene and security in cleanrooms. By dispensing with contact interfaces, these systems significantly lower the chance of contamination, a non-negotiable in environments where sterility is paramount. The entry point is then coupled with access functionalities—think keycards, fingerprint readers or proximity triggers—gatekeeping entry to verified individuals only. The dual layer of protection expedites passage for authorized staff yet enforces the highest cleanliness and security thresholds, fulfilling the increasing demands of contemporary cleanroom operation.

Remote Monitoring and Predictive Maintenance

Cloud-enabled monitoring continuously observes cleanroom roll-up doors via interconnected IoT sensors, delivering live insights on door condition, operational speed, and ambient conditions. Immediate notifications flag anomalies—like increased vibration, alignment drift, or abnormal ingress of particulate—before they escalate into critical failures. Leveraging a deep analytics engine, historical and real-time data calculate the remaining useful life of each component, allowing maintenance schedules to shift from reactive to anticipatory, thereby maximizing door uptime and longevity. When predictive alerts indicate a threshold is approaching, technicians arrive with tailored spare parts and workloads, cutting unplanned shutdowns to a minimum, containing repair costs, and maintaining the controlled environment with micro-level precision.

Cost Analysis and Value for Money

Initial Investment and Operating Costs

To assess the total financial commitment associated with cleanroom roll-up doors, investment-price scrutiny should encompass the following detailed expenditure elements:

Door Fabric and Build

Durable, hygiene-compliant cleanrooms typically specify stainless steel or reinforced PVC as entrance materials; unit pricing fluctuates with panel dimensions, finish specification, and project-specific adjustments.

Integrated Seal-Technology

Contamination barriers within the sealing assembly are engineered to stabilize differential pressures and filth minima. Although upfront rates are marginally elevated, the installation fosters lower life-cycle energy and contamination control costs.

Motor and Control Suite

Rapid-travel actuators, cranial proximity sensing, and configuration software augment capital costs, yet the installation’s energy-siphoning and wear-reduction benefits translate into pronounced savings on the kilowatt and labor fronts.

Commissioning Expenses

Installation facilitated by certified teams guarantees compliance with ISO and GxP protocols; final expenses are proportionate to panel count, environmental conditioning layers, and prevailing wage scales.

Lifecycle Care and Inventory

Scheduled greasing, periodic sealing, and components reservoirs (motors, proximity lenses, etc.) budget an exigent deposit; remote diagnostic tools and trending algorithms thin the budget by forestalling emergent repairs and logging the appropriate mean defects.

Taking the time to weigh each of these considerations enables prospective purchasers to choose wisely, aligning short-term budget limits with the operational gains that will play out over the equipment’s entire lifespan.

Factors Influencing Pricing and ROI

When comparing roll-up doors for cleanroom applications, decision-makers should weigh five influential factors that affect both the purchase price and the overall return on investment:

Material and Construction Quality

Doors fabricated from food-grade stainless steel or high-grade PVC resist decay and contaminants in controlled environments, extending the product lifecycle.

Example Data: A premium stainless steel door may command a 20-30% premium upfront yet typically endures twice the lifecycle of standard grades, justifying the investment.

Automation and Control Features

Doors equipped with proximity sensors, RFID integration, or programmable logic controllers may seem costly initially, yet they minimize manual traffic and strengthen personnel compliance.

Example Data: Facilities that deploy these systems report a 30-40% reduction in door open time, translating into significant savings on indirect labor and product containment.

Energy Efficiency

Insulated lamination, interlocking tracks, and quantitative air leakage ratings collectively limit conditioned air loss, thereby easing the burden on HVAC.

Example Data: Instances show that high-integrity doors can lower HVAC energy expenditures by 15-25% annually, depending on facility load profiles.

Compliance with Industry Standards

Doors designed in conformance with ISO 14644 class ratings or FDA current good manufacturing practice clauses entail rigorous documentation and testing.

Example Data: The incremental price of 10-15% for certified models is rapidly amortized by the avoidance of penalty costs, recall expenses, or product yield losses caused by undue contamination.

Installation and Maintenance Costs

Regional labor tariffs, ceiling height requirements, and the complexity of interface sealing determine the significance of installation service fees, while a negotiated maintenance contract can sustain optimal operation and warranty validity.

Case Study: A building-products manufacturer avoided ten hours of unexpected CNC router downtime by noticing the anticipated end-of-life vibration-profile change detected by the vibration analyzer. Meanwhile, planned preventive work remained on schedule, saving 10% of determined repair costs and preventing 2700 dollars of lost revenue.

Market Trends and Innovations in Cleanroom Roll Up Doors

Emerging Materials and Advanced Designs

The cleanroom roll-up door industry continues to evolve with the introduction of cutting-edge materials and innovative designs, such as rytec doors, to meet stringent industry requirements. Listed below are five noteworthy advancements shaping the market:

Antimicrobial Coatings

Incorporating antimicrobial surface treatments into roll-up doors helps reduce contaminants, ensuring a higher level of cleanliness for critical environments.

Data Insight: Antimicrobial coatings can reduce bacterial growth on surfaces by up to 99%, significantly lowering contamination risks.

High-Performance PVC Fabrics

Specialized PVC fabrics with enhanced durability offer improved resistance to wear and tear, chemicals, and UV exposure.

Data Insight: These fabrics can extend operational lifespans by 25% compared to standard materials.

Transparent Polycarbonate Panels

Transparent polycarbonate inserts provide visibility while maintaining a robust barrier against airborne particles.

Data Insight: Polycarbonate panels are 200 times stronger than glass, offering exceptional durability in high-traffic environments.

Energy-Efficient Insulation Materials

Advanced insulation integrated into the door structure helps regulate cleanroom temperature and humidity levels to ensure compliance.

Data Insight: Energy-efficient materials can reduce HVAC energy usage by up to 15%, contributing to sustainable operations.

Smart Sensors and Automation

Integrated smart sensors enable precise door operations, reducing cycle times and enhancing productivity. These designs align with Industry 4.0 standards for automated facilities.

Data Insight: Facilities that adopt smart automation systems report a 20% improvement in operational efficiency.

Leading Manufacturers and Industry Leaders

Rite-Hite

Renowned for high-speed cleanroom doors engineered to optimize containment while simplifying upkeep.

Market Share: North American cleanroom operators exceed 50% adoption of high performance cleanroom roll-up doors, citing efficiency and compliance.

ASSA ABLOY Entrance Systems

Delivers cleanroom roll-up doors distinguished by tight-seat technology to curb airflow loss.

Performance Metric: End-users realize as much as 30% cut in energy bills thanks to laminated insulation.

Efaflex

Focuses on cleanroom high-speed doors expressly designed for pharmaceutical and semiconductor sectors.

Patent Portfolio: Multiple filings secure secure energy-saving and ultra-rapid sequences.

Dynaco (Entrematic)

Introduces flexible, robust entrance solutions that fortify clean, contamination-controlled spaces.

Quantified Benefit: Drives a 25% increase in air quality retention relative to conventional door technology, per user testimonials.

TMI International, LLC

Delivers bespoke cleanroom portals crafted from compliance-grade materials for diverse sectors.

Distinctive Advantage: Rapid service initiatives and customized six-hour door assembly minimize shutdown periods.

SEPEPES (China)

Established supplier of budget-conscious cleanroom doors that harmonize value and dependable, steady quality.

Competitive Edge: Broad assortment aligns with global cleanroom certifications while keeping lifecycle expenses in check.

Customer Feedback: Noticed their speedy shipping and budget-friendly rates—definitely a viable option if you’re shipping internationally.

Conclusion: Are Cleanroom Roll Up Doors Right for Your Facility?

Core Advantages and Key Decision Factors

When evaluating if cleanroom roll up doors suit your facility, four key benefits and associated consideration points deserve your focused attention.

Effective Contamination Containment

Roll up doors feature precision seals and controlled motion that keep airborne particles to a minimum. By curtailing air transfer and maintaining a consistent isothermal background, they assist your operation in reliably meeting ISO and other demanding cleanroom criteria.

Optimized Floor and Headroom

The vertical-only operation eliminates the footprint risk of door swings, enabling tighter aisle placements and expanded cleanroom layouts. This becomes a compelling point in sharper workflows, rooftop-base constructions, and multi-Level clean environments.

Compressed Cycle and Stable Pressure

Doors that deploy up to 50 inches per second spend the least possible time in the open state, completing the on-demand cycle without compromising differential air pressure. Stable conditions curtail load-cycles on HVAC and reduce batch cycle time.

Proven Robustness and Economic Life

Reinforced PVC, Type 304 stainless, and minimal component assemblies confer both adaptive protection and lasting service. Tracking is within reach, bearings are sealed, and actuators follow a standard schematic, delivering low service load and consistent cost predictability over a fifteen-.

Cleanroom roll-up doors are built from the ground up to satisfy the world’s narrowest cleanroom specifications, including ISO 14644 and the stringent Good Manufacturing Practice standards. By selecting this equipment as part of your cleanroom infrastructure, you guarantee adherence to the highest regulatory benchmarks across life-science, semiconductor, and biopharmaceutical sectors.

Strategic Recommendations for Facility Managers and Architects

For the best results and ongoing compliance when specifying cleanroom roll-up doors, firstly target versions certified against relevant ISO and GMP requirements, as this guarantees continued regulatory alignment. In addition, choose units fabricated from robust low-outgassing materials combined with straightforward, low-wear drive systems, thus assuring long life with modest upkeep. Moreover, evaluate thermal and dynamic performance metrics—specifically, low kVP values and rapid open-close cycles—so that energy losses and facility disruption stay minimized. Finally, work alongside seasoned producers or knowledgeable channel partners; their technical expertise and field data will guide you toward configurations that harmonize precisely with the operational and environmental profiles of the cleanroom.

Frequently Asked Questions (FAQs)

What are cleanroom roll up doors?

Cleanroom roll-up doors are critical components in environments where absolute cleanliness is essential. Engineered with optimal contamination control in mind, these doors use a swift coil-up action to open and close a sealed barrier, cutting downtime to a fraction of a second and locking out unwanted particles before they can enter.

How do high-speed clean room doors benefit cleanroom applications?

By expediting personnel moves in critical spaces, these high-speed doors sharpen workflow while safeguarding sterile zones. A fixed exposure time streamlines traffic, keeping the differential pressure steady and preserving the stringent atmosphere that laboratories, semiconductor fabs, and healthcare settings demand.

What features do cleanroom roll-up doors offer?

To support silent, wear-free motion, doors employ low-friction side tracks and brush seals that silence draft losses. Thoughtful, energy-minimizing profiles close the opening with blunt-force air damurlre, and a flexible PVC curtain pocket layers the barrier for extra shielding against dust and thermal transfer, extending component lifetime and conserving conditioned air.

Are clean room roll up doors compliant with industry standards?

Absolutely, a lot of roll-up doors made for clean rooms meet rigorous industry standards—there are even specific models that carry USDA approval. Whether the need is in pharmaceutical production, food and beverage, or any other application demanding hyper-clean conditions, the design’s engineered for uncompromised hygiene and safety.

What is the role of a clean room door manufacturer in providing high-performance doors?

Manufacturers dedicated to clean-room doors build high-performance roll-ups that fit controlled environments. Their emphasis is to precision and dependability. Each unit is tested to stay sealed without compromise so that temperature and pressure stay within ultra-tolerant limits.

How do roll-up cleanroom doors help control contamination and pressure?

These roll-up clean-room doors control both contamination and pressure by acting as a near-airtight barrier. Since the design incorporates a continuously pressed bottom bar and sealed rail tracks, the door stays locked in place, curbing any seep—be it errant laminar or higher pressure bursts—thereby defending against particle, moisture, or microbe incursion.

What types of applications are suitable for high-speed roll-up doors?

High-speed roll-up doors excel in settings like pharmaceutical manufacturing and food and beverage processing, where speed and sterility are non-negotiable. Their swift, tight seal limits airborne particles, permitting quick traffic without sacrificing contamination control—a must for any controlled environment.

What advantages do high-speed clean room speed doors provide?

Designed specifically for clean rooms, these fast-acting doors deliver measurable benefits. By closing in fractions of a second, they slash energy losses and minimize the duration any surface or operator is exposed to less-controlled outside air. Quiet, reliable performance, matched to stringent cleanliness standards, ensures they fit seamlessly in any tightly regulated facility.

Reference Sources

CAN Bus Communication for Door Control in Cleanroom Environments

Author: Andras Nagy

Publication Date: July 17, 2024

Summary: This paper discusses a building automation system designed to control door interlocking in cleanroom environments, which can include roll-up doors. It provides insights into the communication protocols and hardware used for effective door control in sensitive environments.

Link: CAN Bus Communication for Door Control in Cleanroom Environments

Risk for Contamination in a Cleanroom with Weakened Aerodynamic Barrier

Authors: Lasse Lind Knudsen et al.

Publication Date: October 23, 2019

Summary: This study investigates the risk of contamination in cleanrooms, focusing on the impact of door openings, including roll-up doors, on maintaining an aerodynamic barrier. It provides valuable data on how door design affects cleanroom integrity.

Link: Risk for Contamination in a Cleanroom with Weakened Aerodynamic Barrier

Cleanroom Installations for SRF Cavities at the Helmholtz Institute Mainz

Authors: T. Kürzeder et al.

Publication Date: June 1, 2019

Summary: This paper discusses the installation of cleanroom facilities, including the use of roll-up doors to separate different cleanroom classes. It highlights the engineering considerations for maintaining cleanliness and operational efficiency.

Link: Cleanroom Installations for SRF Cavities at the Helmholtz Institute Mainz

Development of Vehicle Door Side Impact Beam with High Tensile Steel using Roll Forming Process

Authors: H. Son et al.

Publication Year: 2012

Summary: While primarily focused on vehicle door design, this paper discusses roll forming processes that can be relevant for the manufacturing of cleanroom roll-up doors. It provides insights into material properties and structural integrity.

Link: Development of Vehicle Door Side Impact Beam with High Tensile Steel using Roll Forming Process

Rapid Roll-Up Door for Cold Stores

Author: A. Klein

Publication Date: June 25, 1996

Summary: This paper discusses the design and application of rapid roll-up doors, which can be used in cold storage and cleanroom environments. It provides insights into the operational efficiency and thermal performance of such doors.

Link: Rapid Roll-Up Door for Cold Stores

Conclusion

These sources should provide you with a solid foundation for verifying the information in your article regarding cleanroom roll-up doors and related technologies. Make sure to access the articles through your institution or library for full access. If you need further assistance or specific details from any of these papers, feel free to ask!