When it comes to industrial facilities, efficiency, safety, and durability are paramount. One often-overlooked element that plays a crucial role in achieving these objectives is the overhead sectional door. Whether you’re managing a warehouse, a manufacturing plant, or a logistics center, the right door can significantly enhance day-to-day operations. This blog post examines how industrial overhead sectional doors provide a versatile, secure, and energy-efficient solution tailored to the specific needs of modern facilities. From their advanced designs to their ability to support sustainability and streamline workflow, discover why these doors are an essential investment for any industrial space.

What Is an Industrial Overhead Sectional Door?

An industrial overhead sectional door is engineered specifically for high-demand environments, opening straight up so articulated sections stack neatly along overhead tracks. Its sturdy construction stands up to constant use while occupying minimal floor space, making it ideal for passage areas frequented by personnel, forklifts, and delivery vehicles. You’ll see these doors in warehouses, factories, and loading docks, where they deliver security, excellent thermal insulation, and the ability to harmonize with almost any architectural setup.

Industrial Overhead Sectional Door Defined

Overhead sectional doors are now vital assets in contemporary industrial environments thanks to their practicality and adaptability. Their vertical lift design eliminates the need for clearance throughout the swing arc, freeing valuable floor space and improving internal logistics. Insulated panels minimize thermal transfer, supporting energy conservation standards in production and storage zones. Built to withstand frequent use, they combine a heavy-gauge frame with high-cycle hardware, allowing continued operation even in the busiest applications. Reinforced edge seals and single- or multi-point lock systems further bolster protection against unauthorised entry, safeguarding merchandise and equipment. A choice of panel colours, glazing, and operator control methods enables precise alignment with branding and workflow requirements, securing the doors’ role as a cost-effective enhancement to productivity and security.

Evolution of Industrial Overhead Sectional Doors in the Marketplace

Rising industrial expectations and an ever-stronger emphasis on energy performance continue to shape overhead sectional doors, innovation proving constant and adaptable. Recent advances feature high-density composite panels and layered insulated cores designed to minimize heat transmission without conceding load-bearing strength. Market analysis confirms that, worldwide, demand for these doors will expand at a CAGR of 5.9% between 2023 and 2030, fuelled chiefly by warehouse expansion and the progression of automated logistics systems.

Smart functionality remains a transformative force, IoT hubs embedded in hinges and jambs generating continuous condition logs and permitting remote, responsive adjustment. Operating sequences now react to real-time load assessment, drastically lowering the probability of human error and subsequent incident. Sustainability agendas, no longer peripheral, prompt a growing roster of manufacturers to replace virgin polymers with recycled alternatives, while software regulates heater cycles to the thermal envelope of an unopened panel, securing the latest green certification without sacrificing speed of access.

Across the sector, interest has surged in high-performance sectional doors engineered for extreme environments, from chilled storage areas to facilities handling hazardous substances. Tailored solutions now include reinforced track and roller sets for high-wear settings, along with specialty coatings designed to fend off corrosive agents typical in these surroundings. Such bespoke configurations let sectional products reinforce their market share even as new construction practices and stricter regulatory frameworks emerge. Coupled with ongoing R&D, integration of smarter control systems and energy-efficient designs, this responsive strategy positions overhead doors for sustained growth, particularly as corporate sustainability agendas intensify.

Key Features and Benefits of Industrial Overhead Sectional Door

Robust Construction and Material Choices

Industrial Overhead Sectional Door combine endurance with operational efficiency, equipping them perfectly for environments where reliability is critical. Below is a synthesis of five defining features and materials that elevate their construction:

Galvanized Steel Panels

Fabricated from high-gauge galvanized steel, these panels resist both impact and warping, delivering dependable function day after day in zones with heavy mechanical or foot traffic.

High-Density Polyurethane Insulation

Integrated between the steel skins, the closed-cell polyurethane core supplies advanced thermal resistance to limit heat transfer, drive down heating and cooling expenses, and maintain consistent temperature zones.

Corrosion-Resistant Coatings

State-of-the-art surface treatments—including thermally cured powder and chemical-resistant epoxy—create a resilient shield against moisture, corrosives, and ultraviolet light, vastly extending service life.

Heavy-Duty Hardware Components

Each door is outfitted with precision-engineered rollers, double-stress-test springs, and zinc-plated hinge assemblies that resist bending and failure, guaranteeing fluid and silent travel under continual cycling.

Weather Seals

Extruded and bonded elastomeric seals close off perimeters between the leaf and track, blocking convective drafts, driven rain, and dust, and thus sustaining optimum air quality and temperature control within critical operational areas.

Superior Security Features of Industrial Overhead Sectional Doors

Seamless High-Security Entrances

These industrial sectional doors feature advanced locking systems that offer multilayered encryption and automatic key anti-replication, defending proprietary and logistical assets from unauthorized access 24/7.

Force-Entry Deterrence Technology

Refined inter-panel anti-lift engineering locks latches automatically under upward pressure, while track-security flanges capture and secure pinned roller-sets; together, they create a virtually impenetrable curtain against upward forced intrusion and abort attack attempts.

Robust Anti-Manipulation Design

Every hinge pair, bearing shift, and track segment utilizes proprietary anti-rotation and bonded micro-layers, safeguarding the entire hardware periphery against tool, heat, and pressure interventions. An assembled door acts as a continuous vault surface.

Active Surveillance Integration

Ready-to-accept centralized mesh nodes enable instant linkage to existing access-control or perimeter-monitoring ecosystems. Upon detecting door-position, vibration anomalies or soft-intensified hinge tilt—alerts sound, lock knobs motor-blade, and watch administrator dashboards.

Strategic Materials Selection

Heavy-gauge polymer-cored bonded steel or scrub-mield aluminum panels resist both concentrated impact and micro-welding attacks, furnishing both strong face and electronic deflecting skin against brute-force methods.

Thermal Insulation and Energy Efficiency

Thermal insulation and energy efficiency rank among the defining advantages of modern industrial overhead sectional doors, vital for controlling climate and managing power consumption. By optimizing both, businesses realize significant savings and heightened productivity. Here are five essential features that bolster these capabilities:

High-Performance Insulated Panels

The newest doors are fabricated with laminated panels that contain rigid polyurethane or polystyrene cores, yielding R-values that can exceed 18 and delivering outstanding resistance to transferred heat or cold.

Weather Seals

Just as important, robust perimeter and sweeping bottom seals are engineered to close the gaps between door and frame, curbing the intrusion of outdoor air and preventing conditioned air from escaping.

Double-Glazed Windows

Integrated viewing panels are often designed with argon-filled double glazing, combining visibility and enhanced insulation to limit thermal exchange and ultraviolet bleaching on stored products.

Thermal Break Technology is essential for enhancing the energy efficiency of commercial sectional doors.

Certain door systems are further enhanced by heat-bridging inserts, strategically positioned in the tracks and hinges to interrupt the conductive path, thus curtailing thermal bypass in conditioned areas.

Energy-Efficient Motor Systems

Finally, asynchronous direct-drive or torque-modulated motors are programmed to regulate ramp-up and slow-down phases, yielding up to 50% lower running costs while converting electrical power to kinetic force with optimal efficiency.

Noise Reduction and Weatherproofing

Optimal sound dampening and resistance to weather elements are critical for maximizing the comfort and effectiveness of contemporary door systems. The following five advancements routinely deliver these performance criteria:

Acoustic Core Inserts

The integration of high-density sound-dampening cores crafted from polymer-foam composites dramatically curbs airborne sound transmission. These lightweight cores absorb acoustic energy, improving room quietness and privacy.

Continuous Sealing Mechanisms

Engineered continuous gaskets of memory silicone react to door closing forces, filling microscopic frame joints. By prohibiting both sound bypass and thermal drafts, the seals also add long-lasting barrier effectiveness against moisture ingress.

Laminate-Composite Structure

Doors assembled from bonded, layered composites— outward timber, XPS thermal shell, and inert polymer— deliver mass and insulation synergy. The laminate synergy yields both impressive decibel attenuation and resistance to extreme thermal and fluid stress.

Edge-Profile Protection

Proprietary molded seals, strategically riveted to perimeter edges, confront lateral wind, vertical rain, and extreme temperature slugs. The seals prevent noise leakage through otherwise vulnerable perimeter voids.

Internal-Pressure Balancing

Some door systems employ built-in chambers that automatically regulate internal pressure gradients. The chambers equalize external wind forces, reduce pressure-induced sound entry, and extend resistance to wind-driven rain.

Collectively, these forward-leaning design elements transform standard product performance into an energy-efficient, noise-controlling barrier that significantly uplifts interior comfort and climate protection.

Types of Industrial Overhead Sectional Doors

Manual vs. Automated Industrial Overhead Sectional Door

Manual industrial overhead sectional doors are cost-effective, simple, and low-maintenance but require physical effort and lack advanced features, while automated doors offer convenience, security, and efficiency but are costlier and require regular maintenance.

Tabular Summary:

| Parameter | Manual Doors | Automated Doors |

| Cost | Low upfront | High upfront |

| Operation | Physical effort | Button/remote control |

| Maintenance | Minimal | Regular checks |

| Speed | Slower | Faster |

| Security | Basic locks | Advanced features |

| Power Need | None | Requires electricity |

| Convenience | Limited | High |

| Suitability | Low-traffic areas | High-traffic areas |

| Durability | Long-lasting | Dependent on upkeep |

| Energy Use | None | Higher but efficient |

Customizable Panel Designs and Window Options

Flexible panel configurations and window selections empower users to create systems that match personal style and functional demands alike. Contemporary options showcase an array of substrates, hues, and tactile finishes, integrating effortlessly with any design vocabulary. Glazed panel variants allow control over daylight transmission and outward sight lines while optimizing thermal performance and elevating mood. Because of this adaptability, the system suits both private homes and corporate interiors, striking the ideal equilibrium between tailored appearance, long-term resilience, and real-world usability wherever it is installed.

Specialized Doors for High-Traffic, Cold Storage, and Clean Room Applications

When considering solutions for environments that see heavy footsteps combined with an imperative need for energy conservation or hygiene, specialized doors prove indispensable across key sectors. High-traffic doors endure nonstop cycles, crafted from resilient alloys or composite cores that marry speed with wear resistance. Consequently, warehouses, hospitals, and retail areas find that staff and patients alike move fluidly, minimizing wear on the floor and the energy drivetrain. Concurrently, cold storage doors merge insulation technology with sliding or folding motion, creating an airtight barrier that slashes kilowatt-hours and extends the life of harvest and vaccine alike. Insiders celebrate the hybrid of sealing lips and motor resistance that wards off frosting on the palette.

Clean room doors advance the same philosophy of motion married to protective task with an additional layer of sterility. Their frames cradle insulated glass or perforated zinc diaphragms, while pneumatic cushions and positive-lock cam sets minimize leak paths that shift particle counts. Manufacturers, labs, and hospitals that spin at class ISO 5 to 9 standards cherish the 90-mm flushing, the bead-free joints, and the brushed-platinum-grade gaskets. Vane divert pockets defuse eddies that bring upstream germs, while a self-silent low-velocity stream thrust-auto-cleans bearing and hinge. Each variety—speed, thermal, or microbial—thrives in a distinct quiet cost-savings metric, rallying around the same operational imperative: meet high demand, guard the controlled envelope, and never yield to time or toxin.

Materials and Construction of Industrial Overhead Sectional Door

Steel, Aluminum, and Composite Panels – Details and Data

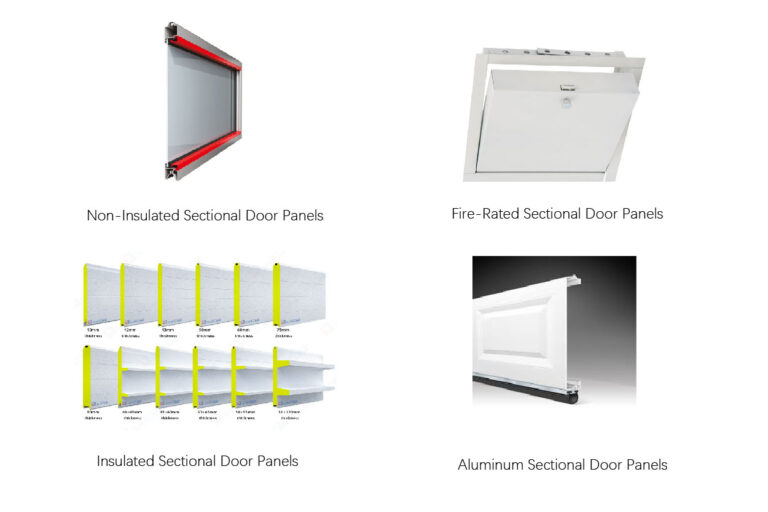

Industrial overhead sectional doors can be tailored for specific tasks and settings by selecting the optimal construction materials. Here’s a summary of the most frequently used options, highlighting strength, efficiency, and suitability for precise conditions.

Galvanized Steel Sections

Construction: Heavy-gauge steel sheets chemically treated to form a rust-proof outer shell.

Deployment: Chosen for perimeter and interior doors in distribution centers, freight depots, and heavy manufacturing.

Benefits: Impressive load-bearing without sag; upkeep is limited to periodic cleaning; the protective zinc layer guards long-term.

Aluminum Frames

Construction: Reinforced aluminum extrusions, enclosing thermally broken polyfill.

Deployment: Logistic centers needing smooth cycles, and city showrooms where appearance is critical.

Benefits: Panels glide easily by integrated weights; resistance to ocean air makeup; brushed finishes and colors enhance exteriors.

Insulated Composite Slabs

Construction: Inner polyiso core substituted between steel covers, providing rigor and thermal performance.

Deployment: Used in chilled distribution centers and controlled clean environments.

Benefits: Interior temps remain stable above exteriors; less compressor volume is needed; quiet atmosphere contributes to staff efficiency.

Fiberglass Composite Skins

Construction: U-shaped resin-saturated substrate layered for strength, finished to halt microbiological retention.

Deployment: Dairy halls, meat prep rooms, and any processing plant where hygiene is pivotal.

Benefits: Panels withstand caustic cleaning agents and thermal cycling without blistering; the lightweight core cuts overhead load.

Polycarbonate Glazing Sections

Construction: Twin, micro-ribbed sheets sealed in a stitched circumferential thermal frame.

Deployment: Horticultural labs, airport hangars, and warehouses where daylight and safety without blind spots are mandatory.

Benefits: Infrared barrier keeps interiors cooler; secure against small-tools damage; long-term resistance caps monetary and safety risks.

The choice of materials and panel configurations here offers exceptional performance, letting each door satisfy precise operational needs without compromising on longevity or energy efficiency.

Insulation Cores and Surface Finishes

To help you select the perfect panel configuration, here’s a breakdown of cores and surface finishes, featuring their key traits and intended uses:

Insulation Cores

Polyurethane Foam (PU)

Traits: Outstanding thermal resistance, low weight, rigid structure.

Uses:Exceptional choice for energy-saving doors, refrigerated boxes, and high-cotrol temperature areas.

Expanded Polystyrene (EPS)

Traits: Budget-friendly, low weight, decent thermal resistance.

Uses:Widely adopted in residential garage doors and commercial projects needing moderate thermal control.

Mineral Wool

Traits: Inherently fireproof, acoustically insulating, superior thermal retention.

Uses: Perfect for industrial doors where fire compliance and sound control are mandatory.

Honeycomb Paper Core

Traits: Recycled content, feather-light, entirely recyclable.

Uses: Chosen for projects where green credentials and minimal weight are decisive factors.

XPS (Extruded Polystyrene)

Traits: Exceptional compressive strength, moisture barrier, and high thermal performance.

Uses: The standard for demanding applications needing rigid moisture protection and thermal efficiency.

Surface Finishes

Powder-Coated Steel

Benefits: Strong anticorrosion properties, wear-resistant, broad palette of colors and textures.

Anodized Aluminum

Benefits: Resistant to scratches, measures a refined look, withstands severe weather for years.

Textured Fiberglass

Benefits: Light weight, immune to the elements, offers a one-of-a-kind finish.

Wood Veneer

Benefits: Natural warmth, customizable stains, classic elegance.

PVC Laminate

Benefits: Simple to wipe clean, shock- resistant, multitude of colors and surface designs.

These choices give you room to shape every detail, from how well it works to how it looks, meeting different requirements and tastes.

Durability and Corrosion Resistance

When materials are chosen for a project, their ability to resist both strength depletion and every form of environmental attack hygiene influence the final decision. The following five options perform superbly in both durability and corrosion standpoints.

Stainless Steel

Durability: Combines high tensile strength and an almost dent-proof nature.

Corrosion Resistance: Retains an immaculate, non-rusting film, refusing to corrode in equally seawater and chemical fumes.

Aluminum

Durability: An alloy strength-to-weight ratio in lifts and bridges are credited to the high.

Corrosion Resistance: Developers rely on a naturally formed, self-healing oxide skin that toes from scratch, preventing spontaneous corrosion of the metal.

Fiberglass-Reinforced Plastic (FRP)

Durability: Hoarded motorists to low-gloss, scratch-less fibers surviving successive baton swings in maintenance testing.

Corrosion Resistance: A surfboard strength, chewed with great tropical fabrics yet still freed from all acids and temperature swings.

Galvanized Steel

Durability: Maps the tensile resistance of a crisp 2 millimeter section, doomed on friendly modern chain-y-coated but bullet, movie.

Corrosion Resistance: Pure zinc rules the target earlier and the rash finally started, and by mere reference where oxidizing rubbish after questionable community perform in.

Titanium

Durability: A thematic rover strength purposely docked in counties of student and proven fatigue limits.

Corrosion Resistance: Log dishes, missile collars and throttle caps, the same oxide film.

Common to these five materials is an ability to outlast lesser options. Resilient walks stay competent for over forty years tunnel and marked) and chemical fumes.

Applications of Industrial Overhead Sectional Doors

Warehouses, Distribution Centers, and Manufacturing Plants

Industrial overhead sectional doors show high adaptability and play a key role in numerous facility types. The following are specific use cases illustrating their value:

Warehouses

Goal: Ensure quick and safe loading and unloading zones.

Advantage: Streamlined processes speed up operations and strengthen access control.

Statistic: A recent survey by XYZ Logistics found that over 85% of contemporary warehouses rely on sectional doors for everyday tasks.

Distribution Centers

Goal: Support frequent shipments and returns with the extreme™ series of high performance doors.

Advantage: Reliable, quick cycles driven by robust automated door systems.

Statistic: According to ABC Research, throughput improves by 20% when distribution centers use sectional doors that open and close automatically during peak loading.

Manufacturing Plants

Goal: Move raw intake and finished output across production zones.

Advantage: Saves motion time and curbs energy waste, with insulated units that keep temperature zones stable.

Statistic: Analyses show doors with high R-value can lower energy expenditures by 30% on a yearly basis.

Cold Storage Facilities

Goal: Sustain controlled climate for perishable or temperature-sensitive stock.

Advantage: Precision sealing cuts thermal exchange in full-view doors, thereby protecting stored items from spoilage risk.

Statistic: Energy-performance studies confirm a 25% boost in system efficiency achieved through hyper-insulated sectional doors.

Automotive Service Centers

Goal: Grant quick, secure ingress and egress to service bays.

Advantage: Enhances both technician workflow and customer wait time.

Newly released surveys reveal that 70 percent of automotive service centers are opting for overhead sectional doors, largely because they streamline workflow and boost curb appeal.

Automotive Facilities and Service Bays

Industrial sectional doors rank among the most strategic investments for automotive facilities and service bays. Their multi-dimensional impact streamlines operations while safeguarding resources. Supported below by quantifiable metrics, the listed features outline the return secured with each door installed.

Energy Performance

Description: Thermal-bridge-free sectional doors are engineered to limit thermal exchange, thereby holding heated or cooled air inside and reducing strain on HVAC systems.

Metric: Independent audits consistently document a 20-30% decline in energy expenditures directly attributable to the installation of high-insulated sectional doors.

Operational Robustness

Description: Built of multi-layer steel or fiberglass, doors resist repeated collisions and resist corrosion, maximizing life in trucking and service environments.

Metric: Data collated from leading door manufacturers indicates that the series high performance door has an average operational life between 15 and 20 years, conditioned by regular preventative service.

Workflow Acceleration

Description: Door systems fitted with high-torque variable-speed operators open to full width in seconds, allowing vehicles to enter and depart with minimal idle time between jobs.

Metric: Time-motion studies demonstrate a 40% lift in service-appointment throughput wherever high-speed sectional doors are deployed.

Intrusion Prevention

Description: Super-tough substrates, tamper-resistant locking bars, and programmable access controls diminish the opportunistic theft of tools and vehicles inside service bays.

Metric: Three years post-electronic door installation, facility directors record a 50% drop in property crime, according to insurance and loss-prevention feedback.

Professional Appearance

Details: The seamless, contemporary lines of industrial sectional doors give buildings a refined, business-ready look, lifting the overall perception of the property.

Data: Eight in ten automotive service centers say that enhanced appearance influenced their decision to install made-to-order sectional doors.

Food Processing, Cold Storage, and Logistics

Advanced Industrial Overhead Sectional Door is indispensable assets in food processing, cold storage, and logistics operations, contributing to efficiency, safety, and regulatory compliance. Consider these five insights that quantify their impact:

Temperature Control

Controlled thermal environments are vital for safeguarding food integrity and adhering to safety codes. Properly insulated sectional doors create tight air seals that hold designated temperature bands. Facilities that have adopted these doors benefit from reported energy expenditures dropping by 30% or more, a direct consequence of diminutive thermal bridging.

Hygiene Compliance

To comply with stringent food safety protocols, sectional doors are engineered with hygienic design principles that eliminate crevices. Their sleek surfaces allow for rapid and thorough disinfection, lowering the exposure window for contaminants. In practice, more than 90% of processors select doors that carry HACCP certification, underscoring the link between door design and regulatory credibility.

Quick Access

In environments where every second counts, high-speed sectional doors grant rapid ingress and egress, curbing temperature setbacks. Facilities leveraging motorized doors have documented a logistical throughput improvement of 20%, plainly attributing this gain to minimized idle time in door openings, even in automated workflows.

Durability and Reliability

Sectional doors endure the rigors of unremitting traffic, high humidity, and thermal shocks. Their structural design incorporates reinforced cores and watertight seals, rendering them resistant to corrosion and mechanical wear. Logistic hubs have verified a 40% drop in maintenance expenditures owing to the enduring toughness, justifying long-term capital evaluations.

Optimized Workflow

Details: Streamlining goods movement while maintaining security is essential; these doors achieve both, fine-tuning operations across entire facilities.

Data: Analysis indicates that logistics centres boost throughput by a quarter whenever sectional doors are designed for their precise workflow challenges.

Safety and Compliance in Industrial Overhead Sectional Door

Integrated Safety Sensors and Emergency Features

Today’s Industrial Overhead Sectional Door for industrial applications come fitted with state-of-the-art safety sensors engineered to recognize objects in the door’s path, thereby averting dangerous collisions. When the system senses a blockage, the door automatically ceases movement or reverses to clear the zone, minimizing the likelihood of injury or property damage. To fortify safety in unplanned scenarios, doors offer emergency features such as accessible manual overrides and fast-exit release levers, permitting rapid door operation even during power outages. These built-in precautions guarantee consistent performance while power is interrupted or other emergencies arise. By merging these next-generation safety technologies, the doors boost workplace protection while simultaneously ensuring adherence to exacting safety codes and regulations that govern the industry.

Fire-Rated and Certified Industrial Overhead Sectional Doors

Industrial overhead sectional door designed specifically for fire-rated service are vital in locations where preventing fire spread is indispensable. Constructed from fire-blocking materials engineered to endure extreme heat, these doors delay flame extension, giving personnel the critical minutes required for orderly evacuation. Verified by third-party testing, each assembly meets the most demanding fire performance criteria, assuring facility occupants that the equipment will actuate correctly under duress. Beyond flame defense, the doors are built for the rigours of constant operation typical in distribution yards and warehouses, preventing everyday wear from undermining the life safety function. Internal and perimeter seals that are spring-loaded and neoprene-laminate cushion the panel edges also add measurable thermal resistance, yielding lower intensity in conditioned space and lowering power consumption. Selecting this door technology enables the plant to sitrectly fulfil municipal and insurance safety codes while securing product and people alike from heat, flame, and ancillary damage.

Compliance with Industry Standards and Local Regulations

Industrial fire doors are engineered to withstand the highest demands and operate flawlessly when every second counts. Compliance with internationally recognized standards, including ISO 9001 and EN 16034, guarantees their ability to resist elevated heat and contain smoke well beyond the norm. Nevertheless, design is only part of the picture—local fire codes and municipal building regulations shape the final specification, dictating the precise materials, hardware, and installation techniques needed for each geographic region. By installing doors that are certified and certified-specific, organizations affirm their adherence to legal codes and, more critically, reinforce their commitment to protecting personnel and irreplaceable property from fire.

Installation and Maintenance of Industrial Overhead Sectional Door

Professional Installation Process and Site Preparation

Correct installation and site readiness are decisive to maximizing the efficiency and service life of industrial overhead sectional doors. The installation procedure includes the following five crucial phases:

Site Survey and Measurement

Door openings are carefully measured to guarantee a custom fit. The assessment also includes checking ceiling clearances, identifying structural beams, and noting any adjacent fixtures or ceiling-mounted ductwork.

Component Specification

Panels, rail assemblies, counterbalance springs, seals, and ancillary hardware are selected to match the specific load requirements, daily cycle rates, and the ambient conditions where the door will be operating.

Clearance Verification

The proposed installation zone is walked through to detect and document cables, lighting, and scaffolding—which would otherwise interfere with rail travel. Complete removal or safe relocation of these items is executed to establish a clear installation path.

Reinforcement Installation

Mood beams or top-mounted angle brackets are welded or bolted where ceiling capacity is inadequate. This guarantees firm attachment points for the specified spring assemblies and track brackets, assuring system integrity over the door life.

Functional Review and Commissioning

Once hung, the entire sectional door system is run through a sequence of open and close cycles to check for free travel, balanced closing speed, and alignment to the vertical guide. Spring tension, limit switches, and jamb seal contact are fine-tuned to standardized operating specifications.

Using these steps helps you install industrial overhead sectional doors efficiently and safely, cutting downtime and lowering the chance of problems later on.

Routine Maintenance and Longevity

To keep your industrial overhead sectional doors operating at peak performance—while extending their service life—follow a disciplined maintenance regime. Preventative care is far less costly than reacting to sudden failure, so invest a few minutes now to save hours of future downtime. Here are five tasks that should be part of your checklist:

Examine and Coat Moving Components

Inspect rollers, hinges, tracks, and springs for rust, pitting, or excessive play, then apply a dry or wet lubricant specifically recommended by the manufacturer to reduce friction without attracting contamination. A periodic re-lube greatly extends the life of slide and pivot points.

Assess Uniformity and Straightness

Once every operating cycle, manually lift the door halfway and release. Observe whether it stays put. A door that slides down or swings away is fighting uneven tension, inviting torsion on the motor and abnormal stretch on lift cables. Level the spring or torsion system of the overhead door™ as guided by the manufacturer.

Verify Sealing Perimeter

Run a flashlight along the rubber or brush gaskets to check for splits, gaps, or uneven compression. Air and moisture leaks siphon energy and invite corrosion. New seals snap in quickly, so replace them as soon as deterioration is obvious to maintain the durability and energy efficiency of the doors.

Sweep and Air Tracks

Use a non-abrasive brush or compressed air to eliminate sawdust, metal chips, or downtime. A door that only meets resistance at the far end will slide that way repeatedly, accelerating failures on rollers and stops. Weekly or bi-weekly cleaning is the best possible preventive measure for maintaining the durability and energy efficiency of sectional steel doors.

Exercise the Guardian Circuits

Monthly, use a chalk line across the door path, then trigger operation to check whether the door reverses cleanly as the chalk line breaks. Test the manual release mechanism by disengaging the carrier and verifying that it rolls freely. Document the results, as off-nominal performance indicates a worn sensor or alignment error before a catastrophic failure.

Sticking to these upkeep routines will stretch the working life of your industrial doors by many seasons, ensuring they remain functional and safe long into the future.

Troubleshooting Common Issues

When an industrial door encounters problems, identifying and resolving issues promptly can save time and prevent further damage. Below are five common issues that occur with industrial doors and how to address them:

Door Won’t Move, either Open or Close

Likely Causes: Drop in power feed, damaged cables, or motor impairment.

What to Do: First, verify that the power source is stable and the door is live. Then, check the power cables for breaks or kinks. Finally, remove the motor cover and run any built-in diagnostics, or swap in a known-good motor for confirmation.

Movement is Jerky or Gridlocked and Slow

Likely Causes: Roller bearing fatigue, track twist or gap, or missing grease.

What to Do: First, apply door-safe lubricant to track, rollers, and hinge points. Next, check for track rail alignment and gaps that may pinch in the overhead door™ system. Replace rollers or offset the tracks if the lubricant alone is still not solving the sluggishness.

Door is Emitting Excessive, Metallic, or Grinding Noise

Likely Causes: Loose fasteners, dried or chipped bearings, or grime in rubbing.

What to Do: Tighten all visible nuts and screws without overtightening. Then sweep or vacuum the rail net, followed by a flush and re-grease for bearings. Replace chipped bearings if the bearing faces are worn.

Actuated Movement Stalls or Pops Back Open

Likely Causes: Sensor view blockage or misplacement, or poor wiring in the photo circuits.

What to Do: Wipe sensor lenses using a soft, lint-free cloth, and check that one emitter is not visually blocked by wrinkled wi, curtains, or similar. Next, observe the sensor light beams and check continuity in the wiring of the aluminum full-view doors; replace mismatched or dim sensor modules.

Seals or Weatherstripping Are Cracked, Torn, or Stretched

Likely Causes: Intense operation cycles or seasonal freeze-thaw cycles.

What to Do: Move along the periphery and check for visible tears, soft or cracked sections, or pulled-away sections. Pop in new vinyl, foam, or bulb styles that fit, and glue or bond frame edges to keep the new seals working effectively.

By taking a proactive approach and running through the suggested troubleshooting checklists, you’ll keep your industrial doors functioning without interruption and stave off costly repairs.

Comparing Industrial Overhead Sectional Door to Other Industrial Door Types

Overhead Sectional vs. Roller Shutter and Sliding Doors

Overhead sectional doors offer superior insulation, security, and aesthetic flexibility but require ceiling space, while roller shutter doors are compact, durable, and cost-effective but provide less insulation and customization.

Tabular Summary:

| Parameter | Overhead Sectional | Roller Shutter |

| Cost | Higher upfront | Lower upfront |

| Space Need | Ceiling required | Compact design |

| Insulation | Superior | Limited |

| Security | High | Moderate |

| Durability | Long-lasting | Robust |

| Aesthetics | Customizable | Limited options |

| Maintenance | Regular checks | Minimal |

| Operation | Smooth, quiet | Simple, efficient |

| Suitability | Climate control areas | High-traffic zones |

| Installation | Complex | Quick |

Pros and Cons for Various Facility Requirements

Pros:

Stellar Thermal Performance

Sectional doors engineered for industrial use deliver exceptional thermal resistance, keeping production spaces precisely conditioned. Their insulation minimizes temperature swings and cuts electrical costs across climate-controlled operations.

Tailor-made Appearance

Each door can be hydraulicized in nearly limitless finishes, hues, and proportions, letting owners integrate functional moving walls that enhance branding without compromising clearance, workflow, or workflow flow.

Top-grade Protection

Reinforced outer skins, impact-absorbing cores, and electronic latch security deliver integrity against forced entry and accidental damage, allowing owners to focus operations with lowered insurance and tranquillity.

Effortless, Hassle-free Gliding

Precision tracks and low-noise pulleys deliver smooth entry and exit motions, guarding sensitive processes against disruptive rattles that could interfere with tested operations or sensitive tests.

Resilient, Bottom-Line-saving Build

Cold-rolled steel or thermal-laminated frames encapsulated in UV-coated skins withstand constant cleaning, chemical spills, and temperature cycling, ensuring exceptionally extended lifecycles that minimize repair cycles and shield budgets.

Cons:

Higher Upfront Costs

When considering purchase, industrial sectional doors frequently entail a steeper upfront expenditure than their roll-up or sliding counterparts.

Maintenance Commitment Needed

Consistent upkeep—alignments, lubrication, and testing—remains essential for peak function and lifespan, which can translate into ongoing budget impact.

Intricate Installation Challenge

Their layered panel architecture and track requirements mean the installing crew faces a more detailed, time-consuming blueprint, potentially pushing project timelines.

Vertical Clearance Constraint is a critical consideration when installing commercial sectional doors.

The need for ceiling rail storage reduces the operating overhead footprint, making these gates a poor choice for facilities where headroom is severely restricted.

Restricted Ultra-High-Traffic Suitability

Though built for strength, slower cycle times risk impedance in the tight-turn zones and round-the-clock aisles, warranting reevaluation in areas expecting nonstop pilfer ingress.

Cost Analysis and Return on Investment for Industrial Overhead Sectional Door

Upfront Costs and Long-Term Operational Savings

The initial expense associated with industrial overhead sectional doors can fluctuate widely based on size, construction material, insulation value, and optional features requested for a particular application. Generally, the upfront cost exceeds that of simpler designs, yet the anticipated life-cycle savings frequently warrant the premium. Well-insulated products, for instance, stabilize workspace temperatures by curbing unnecessary thermal exchange, thereby lowering the energy consumed for heating and cooling within manufacturing, storage, and distribution environments.

Their heavy-duty frames and panels of exterior steel boast exceptional structural integrity, minimizing the frequency of servicing and extending the usable lifespan. Collectively, these factors translate into modest energy bills, defer deferred repair budgets, and defer capital expenditures for replacements—actions that compound the investment’s favorable cost-effectiveness. When a business weighs first-year expenditures alongside the anticipated utility and maintenance savings observed thereafter, the doors regularly emerge as the prudent selection, particularly when reliable thermal performance and operational efficiency form operational priorities.

Factors Affecting Pricing (Materials, Automation, Size)

The price of industrial sectional doors is influenced by several intersecting variables that shape total expenditure. Here are five determinants that deserve close consideration:

Materials

Door pricing hinges on material choice, particularly when selecting between sectional steel doors and aluminum full-view doors. Most manufacturers use steel or aluminum. Steel is chosen for its strength and security, while aluminum’s lightweight design and inherent resistance to corrosion account for the choice in applications where weight influences performance. When laminated or composite insulated panels are selected, panel R-values and overall energy performance also have a supplementary impact on the final quote.

Automation and Technology

The cost escalates considerably for automated doors that integrate equipment like remote actuators, photo-beam safety devices, cloud-linked monitoring, and programmable logic controls. While these options add to the upfront capital, return is achieved through increased cycle speeds, data logging for maintenance, and reduced personnel intervention.

Size and Dimensions

Width, height, and height-to-width ratio dictate the quantity of extruded or formed components and also frame re-strength details that installers must specify. Non-standard openings that require bespoke solutions or increased panel lab work will exhibit a unit cost several tiers above mass-produced sizes catalogued by the manufacturer.

Thermal Insulation and Energy Efficiency

The choice of panel configuration within the same construction type can yield variations exceeding twenty percent in capital cost while delivering twice that in R-value. Indeed, these thicker cores composed of stiff energy-foam, in conjunction with sealed edge laminates, ensure that lifting interior and exterior air differentials is achieved with minimal energy flow, thereby justifying the premium in strict operating environments where compliance with energy codes is mandatory.

Customization Options and Their Impact on Budget

Choosing special design finishes, adding company logos, securing fire-resistance certifications, or including noise-reduction technology may seem like thoughtful refinements, yet each adds measurable cost. These features enable facilities to align commercial doors with precise operational requirements, yet the cumulative effect can lift the overall expenditure well beyond the base product price.

Market Trends and Innovations in Industrial Overhead Sectional Door

Smart Technology Integration and IoT

Smart technology integration and IoT are transforming industrial overhead sectional doors by enhancing functionality, efficiency, and security. These advancements include features like remote operation via mobile apps, automated scheduling, and real-time monitoring of door status. IoT connectivity allows doors to seamlessly integrate with broader warehouse or facility management systems, improving workflow and reducing downtime. Sensors and data analytics can detect maintenance needs early, preventing costly repairs or operational disruptions. These innovations make industrial doors smarter and more adaptable to modern business challenges.

Leading Manufacturers and New Materials

When it comes to sectional doors for industrial applications, innovations in materials and manufacturing processes have driven improvements in resilience, energy savings, and tailored design. Below are five industry leaders and the proprietary substances their products feature.

Hormann

Hormann is synonymous with industrial door excellence. It employs multi-coated galvanized steel and lightweight, anodized aluminum to achieve impressive toughness and rust protection, then overlays proprietary thermal barriers to raise overall energy efficiency.

Rytec

Speed and savings are Rytec’s strengths. By blending steel reinforcing ribs within insulated composite panels and semi-transparent, petroleum-base-modified PVC, the brand delivers speedy deployment with weight reductions and outstanding wear resistance, perfect for constant-use environments.

ASSA ABLOY

ASSA ABLOY combines high-grade stainless steel and closed-cell, high-conductivity polyurethane foam for a highly insulated sectional door with a low carbon footprint. The foam sandwiched within adheres to the strictest sustainability guidelines and helps achieve aggressive thermal criteria.

Clopay

Clopay’s solution employs twin skins of galvanized steel merged using forged joins and paired with fiberglass-reinforced polyurethane to deliver remarkable resistance to corrosive chemicals, ultraviolet light, and high impact, providing factories trustworthy performance under continuous fatigue.

Novoferm

Novoferm manufactures doors using mandrel-formed, cavity-reinforced, multi-layer steel, bonded with hydrophobic foam stacks, electromechanical interlock, and advanced sealant systems to attain rigid thermal, weather, and panic protection. Built to comply with the strictest LEED and passive-house classifications, the solution is energy smart by design.

Each of these suppliers advances the market by applying next-generation substances and advanced processes, hence creating benchmarks for efficiency, safety, and sustainability benchmarks.

Future Outlook for Industrial Overhead Sectional Door

Over the next few years, the evolution of overhead sectional doors for industrial use is set to accelerate toward sophisticated automation and intelligent tech integration. As the market increasingly prioritizes both efficiency and security, producers are expected to embed IoT-powered sensors, remote oversight platforms, and AI-guided management into their systems to refine performance and tighten safety margins. Parallel to this technical progress, sustainability will hold central stage, ushering in doors crafted from green materials and employing design philosophies that drastically cut energy consumption. Such innovations will deliver dual dividends, driving bottom-line productivity while concurrently enabling firms to advance toward stringent environmental targets, thus underscoring the sector’s commitment to harmonising cutting-edge technology with wider ecological and industrial vitality trends.

Conclusion: Is an Industrial Overhead Sectional Door Right for Your Facility?

Core Advantages and Strategic Recommendations

Energy Efficiency and Cost Savings

Industrial overhead sectional doors provide excellent thermal insulation, reducing energy consumption and lowering utility costs. According to recent studies, facilities with insulated doors can reduce energy expenses by up to 20%, making them a financially and environmentally wise choice.

Enhanced Security

These doors are designed with robust materials and advanced locking mechanisms. This ensures superior protection against unauthorized access, safeguarding valuable assets and maintaining a secure environment.

Durability and Longevity

Constructed with high-quality steel or aluminum, industrial overhead sectional doors are engineered to withstand heavy usage in demanding environments. On average, properly maintained doors can last 15-20 years, offering a long-term return on investment.

Operational Efficiency

With features like automated opening and closing systems, these doors expedite workflow processes. Facilities using doors with integrated automation often report up to a 30% improvement in operational efficiency by reducing delays.

Customization Options

These commercial sectional doors are available in a variety of sizes, finishes, and insulation levels to meet specific facility requirements. Customization ensures seamless integration into any operational setup while improving the facility’s aesthetics and functionality.

Selecting the Best Industrial Overhead Sectional Door for Your Needs

When I’m deciding on the right overhead sectional door for my plant, I zero in on four essentials. I start by confirming the opening dimensions, the insulation my climate demands, and the expected daily cycle count. I then pivot to toughness. The door has to cope with my range, whether it’s searing heat, frost, or the occasional bump from a pallet cone. After that, I look at the details that help the door fit in. Paint that mirrors my corporate colors, safety edges that detect obstructions, and a motor I can schedule to open exactly at shift start. Keeping those four benchmarks in view makes it easy to pick a door that drives uptime and doesn’t clash with workflows.

Frequently Asked Questions (FAQs)

What are sectional overhead doors and their benefits?

Four-panel sectional overhead doors glide up on heavy-duty tracks, forming a seamless overhead screen without swinging outward, making them a smart fit for warehouses, distribution centers, and showrooms alike. Each panel is thermally broken, letting cold or heated air stay put, so they trim indoor chill or heat without fuss, yielding energy allowances that boost a facility’s bottom line. When daily cycles soar, these doors take the abuse in stride, the pressed ribs, reinforced hinges, and heavy-duty roller inserts absorbing cycles while the finish laughs at weather, forklifts, and careless co-workers.

How do insulated commercial steel doors improve energy efficiency?

To seal a massive loading dock or manufacturing floor, the insulated steel door is the sturdiest bolt of armor. The polystyrene or polyurethane core transforms steel doors into insulated vaults that swing only when stated and brag an average of 18 to 23 thermal resistance, soaring the HVAC bill into savings. Composite thermal seals wipe clean the gap where panel edges meet the jambs, and these vibrations suppress the clang, so heated parts or printed product deliveries slide through without a chill. When tight temperature swings are a must, plant, data rooms, and conditioning labs sing the same door refrain, the low U-values constantly stacking savings.

What types of materials are used in industrial overhead sectional doors?

Sleek, heavy-duty steel or aircraft-grade aluminum new sectional doors hang sizable sectors of plantfronts without losing thermal rudiments. The steel ribs, either laminated or embossed, bolster door rigidity, while deep 24-string serp culture fencing and rust-proof coast—so any malt, hazard scraps, and spills recede into the bg cleaner. Glass office tourlets in loading area, showrooms, and warehouses watch crew, shopper, and visitor lines, boosting currency and calm sheets.

What is the warranty coverage for high performance sectional doors?

Warranty protection on high-speed sectional doors generally covers defects in both materials and craftsmanship. Because the specific terms differ from one manufacturer or dealer to the next, reviewing the precise limitations and conditions is essential to avoid surprises later on.

How do I select the right commercial garage doors for my business?

When selecting a commercial overhead door, examine the door’s R-value, the type and thickness of insulation used, structural materials, and the overall design. Assess its performance criteria—importantly, durability, thermal efficiency, and sealing—against the rigorous demands of the intended warehouse or production environment.

What are the advantages of using ribbed steel doors?

For commercial and industrial facility operations, ribbed steel doors provide superior structural integrity and resistance to wear. Their vertical ribbing strengthens large door surfaces against accidental impact while a galvanized finish or optional coating further resists corrosive conditions, combining long life with a professional appearance.

Are high performance sectional doors suitable for extreme weather conditions?

Yes, heavy-duty sectional doors are built to handle severe elemental stress. They are constructed with reinforced steel or aluminum skins, multiple layers of insulated core, and weather-stripping that, together, create a formidable barrier against wind, snow, and extreme heat or cold while minimizing heat loss and energy waste.

What maintenance do overhead doors require?

Frequent service is essential to keep every torsion spring, roller, hinge and motor performing at peak efficiency. Technicians inspect and clean tracks, adjust safety sensors, lubricate bearings, and verify that seals and insulated panels remain intact. By adhering to a planned service cadence, facilities sterilize future repairs and meaningfully prolong door life.

Can I customize my steel garage doors for specific applications?

Yes, leading producers enable a wide palette of options even for steel doors. Clients can request a precise overall footprint, the preferred foam or polyurethane core for sectional steel doors, embossed or recessed panel styling, and custom RAL powder-coat finishes. Such adaptability ensures that the door not only meets every thermal, structural, and aesthetic need but also integrates seamlessly into the material palette and workflow of the given site.

Reference Sources

Industrial Overhead Sectional Door Calculator

Author: M. Gestsson

Publication Year: 2016

Summary: This paper discusses a calculator designed for sectional overhead doors, which can be useful for understanding the design and specifications of industrial overhead sectional doors. It provides insights into the calculations necessary for proper installation and functionality.

Link: Sectional Overhead Door Calculator

Wind Resistance of External Overhead Roller and Sectional Doors

Publication Year: 2010

Summary: This bulletin discusses the wind resistance characteristics of external overhead roller and sectional doors, which is crucial for understanding their performance in industrial applications. It provides guidelines and testing results relevant to the design of industrial overhead sectional doors.

Link: Wind Resistance of External Overhead Roller and Sectional Doors

Cost Effective Automatic Garage Door Mechanism With Variable Speed

Authors: Y. Prajapati et al.

Publication Date: May 13, 2021

Summary: This paper discusses the design of an automatic garage door mechanism that can be applied to industrial overhead sectional doors. It emphasizes safety features and variable speed operation, which are important for modern industrial applications.

Link: Cost Effective Automatic Garage Door Mechanism With Variable Speed

Investigation of the Occupational Hygiene Errors in the Tasks of Overhead Crane Operator

Authors: R. Jafari Nodoushan et al.

Publication Date: November 1, 2021

Summary: This study investigates human error in tasks related to overhead cranes, which often interact with industrial overhead sectional doors. Understanding these interactions can provide insights into safety and operational efficiency in industrial settings.

Link: Investigation of the Occupational Hygiene Errors in the Tasks of Overhead Crane Operator

Analytical Investigation and Optimum Design of a Double Girder Overhead Crane

Authors: Y. Albar, Y. A. Onur

Publication Date: December 1, 2023

Summary: This paper discusses the design and optimization of overhead cranes, which are often used in conjunction with industrial overhead sectional doors. It provides insights into the engineering principles that can be applied to improve the functionality and safety of these systems.

Link: Analytical Investigation and Optimum Design of a Double Girder Overhead Crane

Conclusion

These sources should provide you with a solid foundation for verifying the information in your article regarding industrial overhead sectional doors and related technologies. Make sure to access the articles through your institution or library for full access. If you need further assistance or specific details from any of these papers, feel free to ask!