Core Requirements for Industrial Building Entrance Systems

In modern industrial building design, the main entrance of a factory serves as a critical link between logistics systems, personnel flow, and safety protection systems. This area must balance high traffic efficiency, wind resistance, and pressure tolerance, intelligent sensing control, sealing and isolation capabilities, and aesthetic consistency. Therefore, Commercial Security Roll Up Door products must possess high integration and reliability.

Commercial security roll-up doors, particularly those featuring high-speed spiral doors as core technology, are widely adopted in industrial settings due to their structural stability, rapid opening/closing speed, and high safety standards. These doors are commonly used in main access points, logistics terminals, temperature-controlled zones, and high-security environments.

Application Case Study: Customized Application of Commercial Security Roll Up Door in Heavy Industrial Plants

Project Overview

Door Type: High-speed spiral door

Application Scenario: Main entrance of the plant

Door Dimensions: W4000mm × H4500mm

Frequency of Use: Open and closed around the clock, mixed traffic of personnel and logistics

Technical Configuration Plan

| Project | Configuration Specifications |

| Door panel structure | Aluminum alloy double-layer hollow panels with embedded polyurethane insulation core, anodized surface treatment, 40 mm thick |

| Guide rail system | High-strength spiral track, single-panel winding operation to prevent friction between door panels |

| Drive device | Industrial servo motor, rated power 2.2 kW, with 30-meter dedicated power cable |

| Electrical control system | Variable frequency controller + PLC system, supporting signal interlocking and logic configuration |

| Sealing system | Enclosed track system with rear closure panel, compact structure, and excellent airtightness |

| Safety device | Safety photoelectric sensors on both sides, soft bottom edge protection, and intelligent radar zone recognition |

| Opening speed | 1.5–2.0 m/s, adjustable |

| Wind resistance rating | ≥12-grade structural strength suitable for building facades and outdoor passages |

The system has a highly integrated overall structure that balances mechanical resistance, environmental adaptability, and control response efficiency. The door operates smoothly and quietly, making it suitable for continuous use in all weather conditions.

Product Features and System Performance Analysis

Safety Protection Capabilities

The Commercial Security Roll Up Door panel has high impact resistance and can be used as a physical protective barrier to effectively prevent illegal intrusion or accidental contact with the equipment.

The photoelectric safety system covers the bottom of the door and automatically stops or rebounds when a person or object enters the passageway.

The vehicle and pedestrian recognition radar achieves high-precision sensing zoning, reducing false actions and making it suitable for environments with high traffic density.

Airtightness and Environmental Control

The booth-type track structure uses brush strips and a closed wheel system to create a multi-point sealed path, reducing the impact of air pressure fluctuations on the internal working environment.

The rear cover plate is used to enhance the integrity of the door opening closure, improving overall wind pressure resistance and energy isolation efficiency.

Suitable for production space entrances with high cleanliness, temperature, and humidity requirements.

Operational Efficiency and Service Life Performance

The use of a spiral guide rail structure replaces the traditional roller curtain winding method, addressing issues related to friction and aging of the curtain.

The independent track structure enables precise positioning of individual panels, offering superior operational stability and opening/closing speed compared to traditional PVC rapid doors.

The rated opening/closing cycle exceeds 1,000,000 cycles, making it suitable for medium to heavy-duty industrial applications.

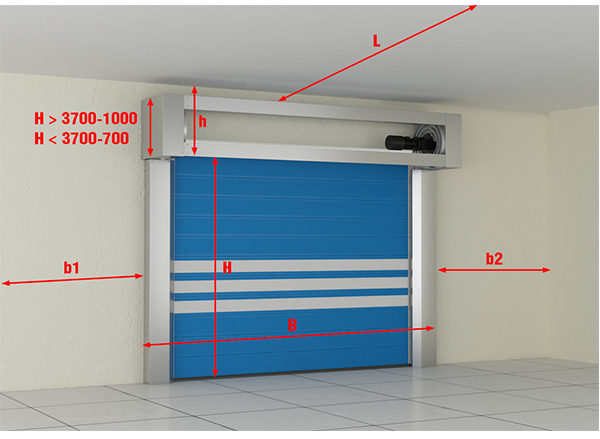

Installation and Structural Embedding Recommendations

Commercial Security Roll Up Door requires high structural precision, so installation locations and control wiring routes must be reserved during the early stages of construction. Installation recommendations are as follows:

| Project | Installation Recommendations |

| Embedded space | Left and right sides of the track ≥350mm, top ≥600mm |

| Wall structure | Concrete/steel structure walls are recommended, with sufficient tensile strength and flatness |

| Power supply configuration | Three-phase five-wire system is recommended, with line cross-section matching the 2.2kW motor power |

| Control wiring | Shielded cables should be used for control lines and sensor lines to avoid signal interference |

| Floor treatment | Avoid ground slopes or height differences that may affect door sealing and photoelectric accuracy |

After installation, perform operational testing and safety verification, including checks on the motor braking system, limit system, radar response range, and photoelectric sensitivity.

Maintenance and Operational Management Recommendations

Although the spiral structure offers exceptional stability, you should establish a regular inspection plan to extend the system’s service life and maintain operational efficiency

Monthly inspection of door operation for any sticking, unusual noises, or difficulty in opening;

Inspection of track cleanliness to prevent foreign objects from causing malfunctions;

Inspect photoelectric sensors, radar sensors, and other sensing components for contamination or misalignment;

Quarterly clean the door panel surface and brush tracks to ensure sealing performance remains intact;

Inspect the control box cooling fan for normal operation and check electrical connections for loosening;

If equipped with an UPS power supply or interlocking module, regularly test the backup power switching function.

Selection Recommendations

Different industrial scenarios have varying requirements for roller door systems. The following are selection recommendations based on actual project experience:

| Application Types | Recommended structural forms | Special considerations |

| Main Entrance of Exterior Wall | Spiral-type hard doors | Strong wind protection, personnel safety, intelligent recognition |

| High Cleanliness Area Entrance | Fully sealed high-speed roll-up doors or turbine doors | Air tightness, isolation capability, cleanliness control |

| Intelligent Logistics Channel | PLC-linked high-speed doors | Response time, compatibility with AGV/scanning systems |

| Indoor Area Partition | Standard high-speed PVC doors | Lightweight structure, low noise operation, cost control |

FAQ

Q1: Are turbine-type high-speed doors suitable for frequent opening and closing?

Yes, they have a million-cycle opening and closing lifespan and are suitable for high-frequency entrances and exits.

Q2: How is the sealing performance?

Through the enclosure track, rear cover plate, and sealing strip structure, they achieve better overall sealing performance than traditional roller shutter doors.

Q3: Can it be applied to smart factories?

It supports integration with MES systems, barcode scanners, radar, and magnetic sensors to achieve automated access management.