Why is it important to choose the right dock leveler in warehouse?

In modern warehouses and logistics centers, the dock leveler in the warehouse is one of the core pieces of equipment that ensures efficient loading and unloading operations. Its role is to compensate for the height difference between the warehouse platform and the truck to ensure smooth, fast, and safe loading and unloading of goods. Choosing the right warehouse loading and unloading platform not only improves operational efficiency but also reduces damage and safety hazards caused by improper loading and unloading.

Different types of warehouse loading and unloading platforms have different operation methods, functions, and applicable scenes. In this article, we will introduce various types of warehouse loading platforms in detail and help you make the best choice according to your warehouse needs.

What is a dock leveler in warehouse?

A dock leveler in the warehouse is a mechanical platform that is used to connect a truck loading or unloading goods to a warehouse platform. Its main function is to compensate for the difference in height between the truck and the warehouse platform to ensure smooth loading and unloading of goods. A dock leveler not only increases the speed of loading and unloading, but also reduces the risk of injury and damage to goods, and improves the overall efficiency of the warehouse.

Types and features of warehouse loading platforms

When choosing the right warehouse loading platform, you need to consider the weight of the goods, the frequency of unloading, and the environment in which it will be used. Below are a few common types of warehouse loading platforms:

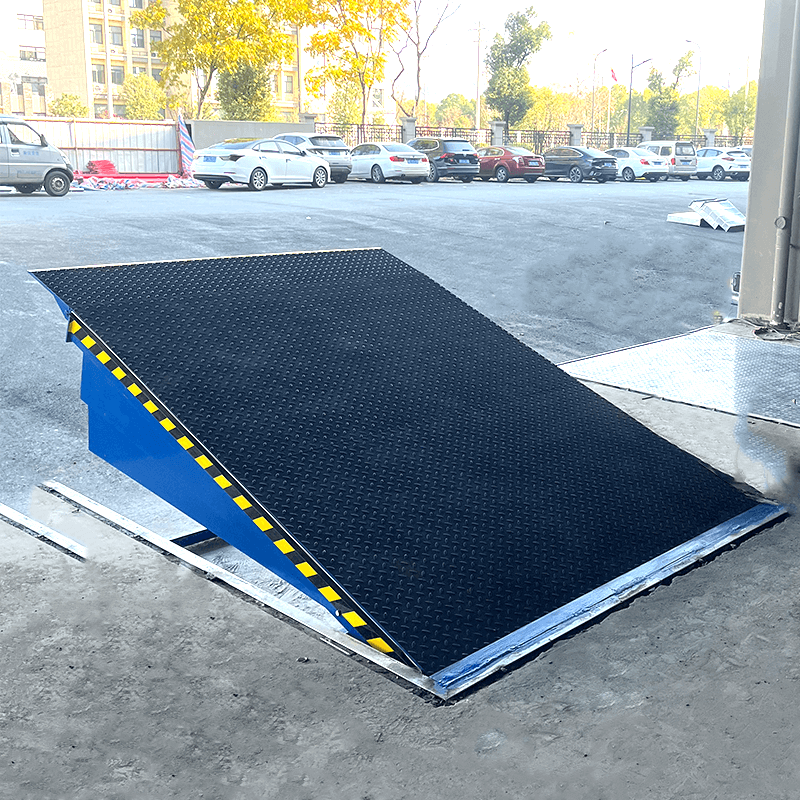

Mechanical Dock Leveler

Features

Manual operation: the height of the platform is adjusted by a lever or wheel mechanism.

Simple structure: easy to operate, suitable for low-frequency use.

Low cost: Compared with other types of loading and unloading platforms, the initial investment of a mechanical dock leveler is low.

Advantages and disadvantages

Advantages:

Low initial investment, suitable for enterprises with limited budget;

Low maintenance cost, simple structure, not easily damaged;

Does not require electricity, suitable for areas with unstable electricity.

Disadvantages:

Slower operation and lower efficiency;

Suitable for low-flow environments, high-flow places may not be efficient.

Suitable for occasions

Low-flow warehouses;

Small plants and low-frequency loading and unloading occasions.

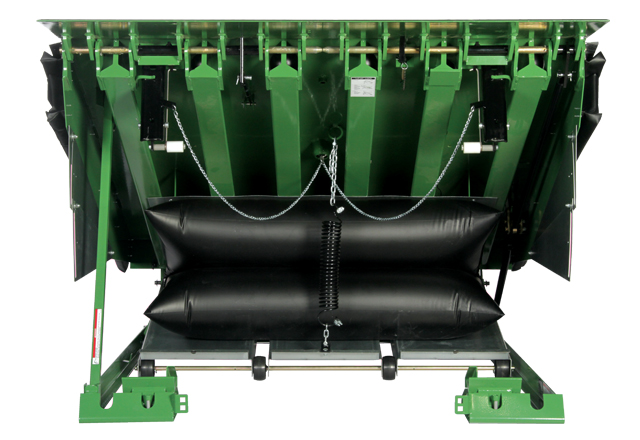

Hydraulic Dock Leveler

Source from: SEPEPS

Features

Hydraulic operation: Raising and lowering the platform by means of a hydraulic pump provides smooth operation.

Fast speed: for high traffic environments where fast loading and unloading is required.

Flexible Adjustment: The platform can be flexibly adjusted to accommodate trucks of different heights.

Advantages and Disadvantages

Pros:

Fast operation and improved loading and unloading efficiency;

Adaptable: height can be adjusted to fit different types of trucks;

Reduces manual labor and improves safety.

Disadvantages:

Higher initial investment, more expensive than mechanical platforms;

Requires electrical support and therefore relies on the availability of electricity.

Suitable occasions

High-traffic warehouses;

Logistics centers;

Large-scale production plants and applications requiring efficient loading and unloading.

Air Powered Dock Leveler

Source from: kelleydocksolutions.com

Features

Air cushion operation: using air pressure to lift the platform, suitable for some special environments.

Less parts: using pneumatic system, reducing mechanical wear and tear, low maintenance cost.

Efficient and fast: suitable for high frequency loading and unloading and fast operation.

Advantages and Disadvantages

Advantages:

Efficient and fast, ideal for high traffic and high frequency working environments;

Low maintenance costs, using fewer mechanical parts;

Smooth operation, suitable for places where delicate handling is required.

Disadvantages:

Requires an air compression system with high equipment requirements;

High initial cost, requiring additional compressor installation.

Suitable occasions

Warehouses with high frequency loading and unloading;

Special environments such as flammable gas or chemical storage areas.

| Type | Operation method | Advantages | Disadvantages | Applicable occasions | |

| Mechanical dock leveler | Manual operation | Low initial cost and easy maintenance | Slow speeds for low traffic situations | Low-volume warehouses, small factories |

| Hydraulic dock leveler | Hydraulic operation | Fast and efficient, adapts to different truck heights | High initial cost, dependent on electricity | High-traffic warehouses, logistics centers, heavy-duty places |

| Air cushion dock leveler | Pneumatic | Efficient, easy to maintain, smooth operation | Requires stable gas supply, high energy consumption | High-frequency loading and unloading warehouses, special environments |

How to choose the right warehouse loading dock?

When choosing the right warehouse loading dock, you need to consider several key factors:

Warehouse size and traffic flow

For low-traffic, low-frequency warehouses, a mechanical loading dock may be a cost-effective option;

For high-traffic, high-frequency warehouses, hydraulic loading platforms or air-cushion loading platforms can offer greater efficiency.

Weight capacity

Ensure that the platform you choose is capable of carrying the weight of your goods. Hydraulic and air cushion loading platforms are usually suitable for heavier loads, while mechanical loading platforms are suitable for lighter loads.

Safety and security features

Consider choosing a loading dock with crash protection and safety sensors, especially in high-traffic areas that are frequently utilized, as these features protect employees and equipment.

Environmental conditions

Choose a loading dock that is adapted to your warehouse environment. If your warehouse is often subject to extreme weather conditions or has a need for temperature variations, a weather-resistant hydraulic or air-cushioned platform may be more appropriate.

Maintenance and upkeep of warehouse loading platforms

To ensure the efficient operation of your warehouse loading dock, regular maintenance and servicing is essential. Below are some common maintenance recommendations:

Regular inspection and cleaning

Check hydraulic oil and gas pressure to ensure smooth operation of the equipment;

Clean the rollers, tracks and door curtains on the platform to avoid dirt buildup;

Regular inspection of seals to ensure no damage and avoid energy loss.

Lubrication and Regulation

Lubricating the hydraulic unit and moving parts to reduce friction and prolong service life;

Adjusting the height and sensitivity of the platform to ensure it runs smoothly.

Professional Inspection

In order to ensure that the hydraulic or pneumatic system is functioning properly, it is recommended that a professional inspection be carried out once a year to ensure that there are no oil leaks, gas leaks or other problems.

How to pick a reliable warehouse loading dock supplier?

Supplier experience and reputation

Choose a supplier with extensive experience and good reputation in the industry. Find out about the supplier’s expertise by reviewing customer reviews, success stories and feedback from other users.

Product quality and certification

Ensure that the supplier provides products that comply with international quality standards such as ISO 9001, which can guarantee the safety, durability and efficiency of the loading platforms.

Customer support and after-sales service

Choose a supplier that provides comprehensive after-sales support to ensure timely technical support and maintenance services during use. Suppliers that offer long-term warranty and on-site service are usually more trustworthy.

The best choice for warehouse loading docks

Choosing the right warehouse loading dock is critical to improving operational efficiency, safety and reducing energy consumption. Whether you choose a mechanical, hydraulic or air-cushioned loading dock, the decision should be based on the characteristics of your warehouse, the type of goods and the flow requirements. With regular maintenance and by choosing a reliable supplier, you will be able to maximize the return on your loading dock’s investment and ensure efficient operation for a long time.

FAQ: Frequently Asked Questions

1. What is the service life of a warehouse loading dock?

The service life of a warehouse loading dock is usually 10 to 15 years, depending on the frequency of use and maintenance.

2. How do I know which loading dock is right for my warehouse?

Depending on the size of your warehouse, the weight of your goods, the flow requirements and the environmental conditions, you can choose the most suitable loading dock.

3. Does a warehouse loading dock need regular maintenance?

Yes, regular inspection of the hydraulic system, seals and electric components, as well as regular cleaning and lubrication can effectively extend the service life of the loading dock.

4. Can I install my own loading dock?

Although mechanical loading/unloading platforms can be self-installed, installation of hydraulic and air cushion platforms is recommended to be carried out by professionals to ensure proper operation and compliance with safety standards.