Why is measurement the “first lifeline” for rapid door engineering?

Rapid doors typically operate at speeds between 1.0-2.0 m/s. This high-frequency, high-inertia operation demands exceptional structural stability from the door assembly.

Energy Efficiency: Precise measurements ensure minimal gaps between the door and wall. Combined with EPDM seals, this can effectively reduce HVAC energy consumption by 15%-25%.

Equipment Lifespan: Exceeding measurement tolerances (typically requiring linear tolerances within ±1/16 inch) causes track distortion, overloading servo motors and shortening drive system lifespan.

Safety Compliance: Installation meeting CE/EN 13241 standards fundamentally depends on a qualified physical mounting interface.

Core Measurement Principles: Indoor, Three-Point, Maximum/Minimum

According to the latest installation instructions, measurement work must strictly adhere to the following three principles:

Indoor Measurement Principle: Since the drive system, control box, and tracks of rapid doors are typically installed indoors, all valid data must be obtained from the indoor side of the door opening.

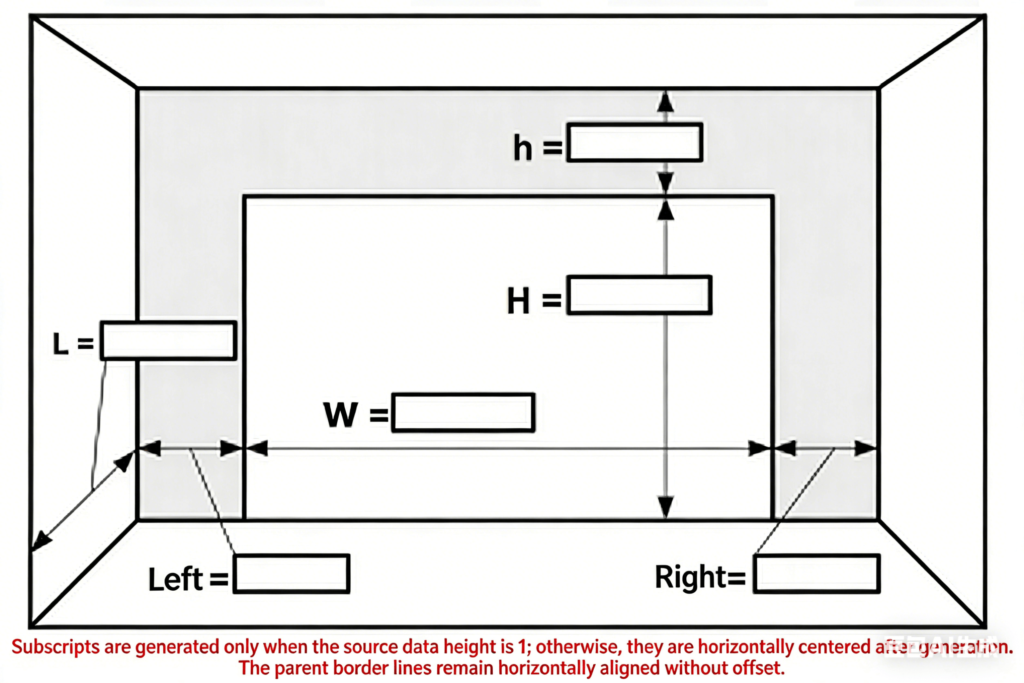

Three-Point Measurement Method: Door openings may exhibit tilting or settling. Measurements must be taken at a minimum of three positions: left, center, right (height) and top, center, bottom (width).

Maximum/Minimum Value Logic:

Door Opening Clear Width (W/B) and Clear Height (H): Take the maximum value from the three-point measurements. This ensures the manufactured door panel fully covers the opening, preventing air leakage.

Headroom (h) and Side Clearance (b1/b2): Take the minimum value from the three-point measurements. This ensures the door header rollers and side tracks can still be installed smoothly at the narrowest points in the environment.

Detailed Explanation of Key Geometric Parameters (Based on SEPPES Latest Standards)

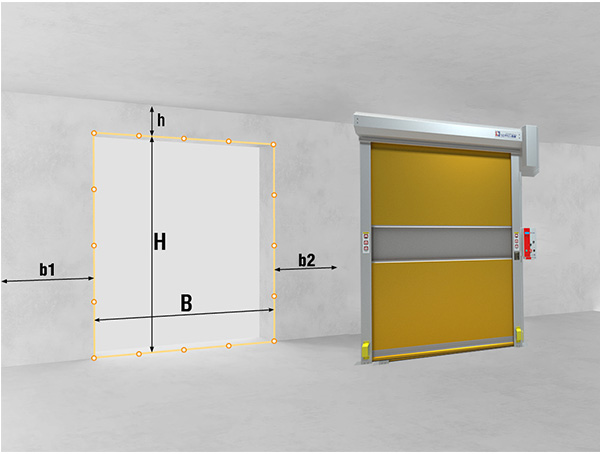

1. Door Opening Height (H) and Width (W/B)

These are fundamental data points determining logistics accessibility. When measuring height, the highest point of the floor must be identified. If the floor is uneven, the bottom airbag sensor may experience frequent rebound or seal failure due to uneven force distribution after installation.

2. Headroom (h) Standard Requirement: For standard rapid roll-up doors, a minimum 600mm clearance above is recommended. Functional Purpose: This space accommodates the aluminum alloy roller shaft, motor bracket, and housing box. Insufficient headroom may necessitate switching to an external installation mode or employing a specialized low-headroom track solution.

3. Side Clearance (b1/b2) Non-motor side: Reserve at least 200mm for installing guide rail brackets and safety photoelectric sensors. Motor side: Reserve 500mm to accommodate the servo motor (industrial shaft-driven opener) and control box. Obstacle avoidance reminder: When measuring, check for potential obstructions on the side wall such as fire hydrants, electrical distribution boxes, or downspouts.

In-Depth Assessment of On-Site Installation Conditions

A comprehensive On-Site Measurement Confirmation Form should also include an examination of the physical environment:

1. Wall Structure Load-Bearing Capacity

Brick-concrete structure: Confirm whether reinforced lintels are present; use chemical anchors when necessary.

Steel structure: The most ideal interface. Confirm the thickness of structural steel (recommended ≥3.0mm) to ensure the strength of welded or bolted connections. Color-coated sandwich panels: Extremely low load-bearing capacity. Must add square steel (50mm x 100mm or larger) inside the door opening as a secondary frame.

2. Electrical Environment and Power System

Power source location: Confirm power source distance. Typically requires single-phase 220V or three-phase 380V power within 5-10 meters of the motor.

Motor Position: Select left-side, right-side, or front-mounted installation based on on-site operational convenience.

3. Environmental & Wind Resistance Requirements

For installations at building exteriors, select the “Enhanced Wind Resistance” option. SEPPES sectional doors or stacking doors withstand winds exceeding Category 10 (EN 12424 Class 3-5).

Installation Precautions and Common Pitfalls

Track Verticality and Parallelism: When installing tracks, a laser level must be used. If the two tracks are not parallel, the door curtain will experience severe friction during operation, causing the motor to overheat and trigger an alarm.

Safety Device Calibration:

Infrared Photoelectric Sensors: Must be precisely aligned to prevent false stops caused by dust interference.

Bottom Safety Airbag: Wiring must remain flexible to prevent cable breakage during frequent start-stop cycles.

Limit Switch Settings: During initial operation, manually adjust the encoder limit switches to ensure the door does not collide with the overhead housing when fully open and that the bottom seal tightly contacts the floor when closing.

Summary: Transforming Data into Benefits

An adage in the industrial door industry goes: “Product quality accounts for 30%, while measurement and installation account for 70%.” By strictly adhering to SEPPES’ three-point measurement method and the 500mm motor clearance rule, you can avoid over 90% of potential post-installation maintenance issues. For large-scale factory door opening retrofits, it is recommended to compile the measurement data into a standardized matrix table, signed off by the project manager, civil engineering lead, and manufacturer. This serves not only as technical documentation but also as a contractual safeguard ensuring timely project delivery and long-term operational efficiency.

Reference Sources

SEPPES Technical Encyclopedia: https://seppesdock.com/fr/blog/industrial-overhead-sectional-door-comprehensive-guide/

Industrial Door Selection and Application Guide: https://workshopdoor.com/warehouse-industrial-door-professional-selection-and-application-guide/

SDI (Steel Door Institute) Measurement Standards: https://steeldoor.org/sdi-135/