In modern logistics and warehousing, loading and unloading platforms are indispensable to efficient operations. Different dock platforms – such as manual dock leveler and hydraulic dock leveler – each have their characteristics and advantages. How to choose the right loading and unloading platform for your business needs is directly related to the efficiency, safety, and long-term cost of your organization. In this article, we will compare the two types of loading and unloading platforms in detail from multiple perspectives, to help you find the best solution to cope with the loading and unloading needs in different scenarios, and to improve the overall operational efficiency.

Why is choosing the right loading dock critical?

Efficient and safe loading and unloading platforms are indispensable facilities for the logistics, warehousing, and manufacturing industries. The role of the loading platform is to connect the truck with the loading platform to ensure the safe and smooth flow of goods. Common types of loading platforms include manual loading platforms and hydraulic loading platforms, with significant differences in operation, scenarios, and performance.

What is a manual loading platform?

Definition and working principle

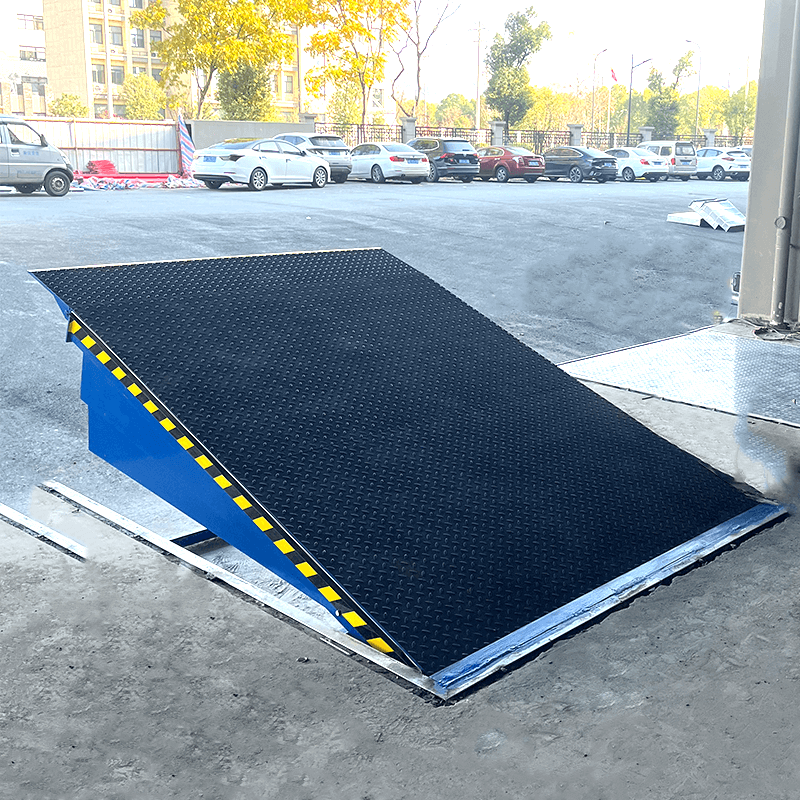

A manual loading platform is a manually operated mechanical device that adjusts the height of the platform to match the height of the truck compartment using a system of zippers, levers, or springs.

Main features

Simple operation: manual adjustment using levers or zippers.

Durable design: usually made of high-strength steel.

No Electricity Required: No power supply is required, making it suitable for locations where electricity usage is limited.

Advantages of manual loading platforms

Low cost: The initial purchase cost is low.

Simple maintenance: fewer mechanical parts, and lower maintenance costs.

Suitable for low-frequency operation: Suitable for locations with low loading and unloading requirements.

What is a hydraulic dock leveler?

Definition and working principle

The hydraulic dock leveler realizes the automatic adjustment of platform height through the hydraulic system and electric drive. The operator only needs to press a button to complete the whole lifting and lowering process.

Main features

Fully automated: height adjustment is accomplished by an electro-hydraulic system.

Enhanced safety: equipped with emergency stop and overload protection.

Strong load-bearing capacity: suitable for high load and frequent operation scenarios.

Advantages of hydraulic loading and unloading platform

Efficient operation: Push-button operation, fast completion of loading and unloading tasks.

Enhanced safety: reduced risk of injury in the workplace due to less human involvement.

Long-term cost-effectiveness: low operating costs and higher ROI despite higher initial investment.

Manual VS Hydraulic Dock Leveler: Key Comparison

| Comparison Program | Manual Dock Leveler | Hydraulic Dock Leveler |

| operating method | Manually operated and dependent on labor | Fully automatic, push-button control |

| Initial cost | relatively low | high |

| Efficiency | Suitable for low-frequency operation | Suitable for high-frequency, high-intensity operation |

| Safety | Provide basic security features | Equipped with advanced safety systems |

| Maintenance requirements | Low maintenance, simple lubrication | Regular checking of hydraulic oil and motor |

| Durability | Long service life, but not suitable for high intensity use | Designed for heavy-duty and high-frequency operation |

| Power consumption | No electricity required | Requires electrical support |

| Ergonomic design | Requires more physical effort and is easily fatigued | Easy operation and reduced physical labor |

Application scenarios: How to choose the right loading dock leveler?

Application scenarios for manual dock leveler

Small warehouses: places with low loading and unloading frequency and limited budget.

Areas with limited access to electricity: Places without a stable power supply.

Budget-sensitive companies: Small and medium-sized enterprises pursuing low-cost equipment.

Scenarios for hydraulic dock leveler

Large logistics centers: Places that require high-frequency loading and unloading of goods.

Cold chain transportation and warehousing: need to reduce the opening time of temperature-controlled areas and maintain stable temperatures.

Manufacturing factories: production line environments with high-efficiency loading and unloading requirements.

How to choose the right loading platform for your needs?

Evaluate the frequency of operation

Manual dock platforms can be chosen for sites with low loading and unloading frequencies, while hydraulic loading platforms are more suitable for high-frequency operations.

Consider budget and long-term costs

While manual loading platforms are less expensive, they can lead to additional labor costs in high-intensity use scenarios. Hydraulic loading platforms, on the other hand, despite a higher initial investment, offer long-term savings through reduced labor intervention and increased efficiency.

Focus on safety

If the work environment requires a high level of safety, such as when high loads are involved or when cargo is unstable, it is more appropriate to choose a hydraulic loading platform with advanced safety features.

The Long-Term Value of Hydraulic Loading Platforms

Although the initial cost of a hydraulic dock platform is higher than that of a manual dock leveler, the increased efficiency, safety, and long-term cost savings it brings make it the best choice for high-demand locations. Its fully automated features not only reduce labor intensity but also dramatically increase the speed and safety of loading and unloading work, making it a smarter investment in the long run.

Conclusion

There are advantages and disadvantages to both manual and hydraulic loading platforms, and choosing the right equipment needs to be a combination of your organization’s specific needs and budget. If your loading and unloading needs are low-frequency and your budget is limited, a manual loading platform is a reliable and economical choice. For high-frequency and high-efficiency loading and unloading scenarios, hydraulic loading platforms are undoubtedly a better solution.

Through the analysis in this article, you can choose the most suitable loading/unloading platform according to your actual needs, optimize your work efficiency and improve safety.

Frequently Asked Questions (FAQ)

1. What is the main difference between a manual loading platform and a hydraulic loading platform?

Answer: Manual loading and unloading platforms rely on manual operation and are suitable for low-frequency use, while hydraulic loading and unloading platforms use automated systems and are suitable for high-efficiency and high-intensity operation.

2. Which type of loading/unloading platform is safer?

Answer: Hydraulic loading and unloading platforms are equipped with advanced safety features, such as emergency stop and anti-skid devices, which are safer.

3. Which places are manual loading/unloading platforms suitable for?

A: It is suitable for small warehouses with limited budget or places with limited electricity.

4. Do hydraulic loading platforms require regular maintenance?

A: Yes, the hydraulic fluid, motor and sensors need to be checked regularly to ensure proper operation.

5. Is it worth investing in a hydraulic loading dock?

A: If your loading and unloading needs are high frequency and you require high efficiency and safety, a hydraulic loading platform is a smart choice for long term cost savings.