Distribution Centers are a crucial part of the logistics industry, involving the entire process from warehousing to distribution. With the continuous development of logistics and e-commerce industry, efficient and safe door system plays a vital role in improving the efficiency of warehousing, ensuring safety and reducing energy consumption.Distribution Centers Doors not only require high-frequency opening and closing ability, but also need to have good sealing, durability and safety to adapt to the complex working environment.

This article will detail the various door body types suitable for Distribution Centres and provide insights into how to select the right door body to meet different warehousing and logistics needs. By comparing the various types of door bodies, technical parameters and application scenarios, it will help industry users make informed decisions.

What are Distribution Centers Doors?

Distribution Centers Doors are industrial doors specifically designed for use in locations such as distribution centers and warehouses. They need to have several key features: efficient opening and closing functions, excellent sealing, durability and the ability to adapt to different working environments. As the logistics industry’s demands for timeliness and safety continue to increase, choosing the right door body is one of the keys to improving overall efficiency.

These door bodies are used in a wide range of applications, including cargo handling, temperature-controlled environmental protection and high-frequency operations. By choosing the right door body, not only can you improve efficiency, but you can also effectively reduce energy consumption and minimise breakdowns.

Types of Distribution Centres Doors and Applicable Scenarios

High Speed Roll Up Doors

Applicable scenes: high-frequency opening and closing of the warehouse entrance, goods sorting area

Characteristics:

Rapid opening and closing: opening and closing speed of 0.8-1.4 metres per second, reducing waiting time for operation and improving work efficiency.

Good sealing performance: reduce the entry of external pollutants to ensure a clean environment.

Strong durability: wear-resistant, impact-resistant, suitable for high-frequency use.

Reason for use: logistics centres need fast flow of goods, choose high speed rolling door can improve efficiency and reduce stopping time.

High Speed Stacking Doors

Applicable scenes: large cargo transport area or high-frequency access to the channel

Characteristics:

Space-saving: the door body can be stacked at the top when it is opened, reducing the floor space.

Strong wind resistance: wind resistance up to 600Pa, adaptable to windy weather.

Efficient opening and closing: supports fast opening and closing.

Reasons for use: suitable for large warehouses or logistics centres in the area of goods transport, especially for the need to save space in the large opening area.

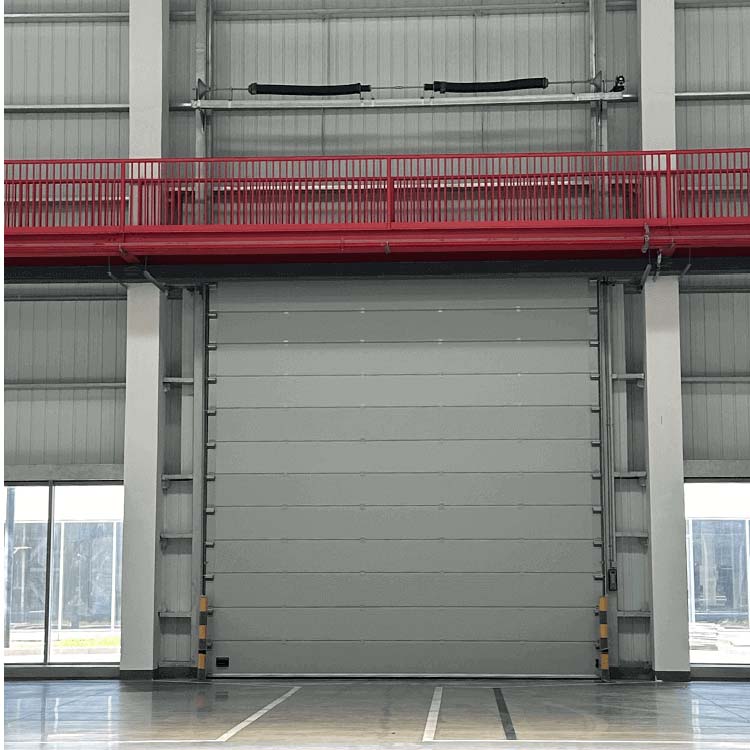

Industrial Lifting Doors

Scenario: suitable for stronger insulation performance of the production workshop, warehouse

Characteristics:

Strong thermal insulation: good thermal isolation, suitable for temperature-controlled environments.

Strong wind resistance: the door body adopts sturdy sectional design to adapt to different climatic conditions.

Sturdy structure: durable and high strength, suitable for heavy load places.

Reason for use: For warehouse environments that require temperature and humidity control, industrial liftgate can effectively save energy and maintain the temperature inside the warehouse.

Insulation High Speed Doors

Applicable scene: cold chain warehouse, temperature-controlled storage area

Features:

Excellent thermal insulation performance: U-value <1.0 W/m²K, keeping the temperature stable in the warehouse.

Energy saving and environmental protection: Reduce energy consumption and lower operating costs.

Adaptation to extreme temperatures: adapts to temperature ranges from -30°C to +50°C.

Reasons for use: Suitable for distribution centres with strict temperature control requirements, especially for storage areas for foodstuffs, pharmaceuticals and other goods with high temperature requirements.

Fast Action Doors

Applicable scenes: temperature-controlled warehouses, warehouses with clean environment requirements

Features:

Fast closing: complete the opening and closing of the door in a short time to reduce heat loss.

High sealing: prevent outside air from entering, keep the internal environment stable.

Anti-pollution: the door body material is dustproof and waterproof, adapting to places with high cleaning requirements.

Reasons for use: quick closing doors are suitable for places with high cleaning and temperature control requirements, especially in distribution centres in the food and pharmaceutical industries.

Why is it important to choose the right Distribution Centres Doors?

Improve operational efficiency: By choosing the right type of doors, you can significantly improve the efficiency of access to your warehouse or distribution centre. Fast opening and closing doors reduce waiting times and speed up the flow of goods.

Reduce energy loss: The right door has better sealing performance, reducing hot and cold air loss, thus reducing energy consumption and saving operating costs.

Ensure safety: Choosing a door body with wind resistance, anti-collision and safety sensors can effectively avoid accidents and protect the safety of warehouse staff.

Adapt to different environmental requirements: distribution centre doors need to be selected according to different environmental requirements (such as temperature control, humidity, corrosion, etc.) to ensure good operation of the door body under different working conditions.

How do I choose the right Distribution Centers Doors for my actual needs?

When choosing the right Distribution Centers Doors, you need to consider the following key factors:

Operating Frequency and Opening and Closing Speed

High-frequency operation: For warehouses and logistics centres with high-frequency operation, it is recommended to choose doors with faster opening and closing speeds, such as high-speed roller shutter doors and speed closure doors. That can significantly improve the efficiency of entry and exit.

Low-frequency operation: for areas that do not need to be opened frequently, you can choose industrial lifting doors and other doors suitable for large openings.

Environmental requirements

Temperature-controlled environment: for cold chain logistics or the need for heat preservation of the environment, the choice of heat preservation effect of the door. Such as heat preservation of high-speed doors and industrial lifting doors.

Clean environment: clean room and high hygiene requirements of the region need to choose high sealing doors, such as speed closed door and high-speed zip door.

Safety and wind resistance

For large opening areas or warehouses exposed to harsh climatic environments, doors with high wind resistance should be selected, such as high-speed stacking doors and industrial lift doors.

Space utilisation

Space-constrained areas: If the warehouse has limited space, it is recommended to choose door bodies that can save space, such as high-speed stacking doors, which can be stowed at the top when opened.

Conclusion

Choosing the right Distribution Centers Doors not only improves logistics efficiency, but also effectively reduces energy consumption, ensures security, and adapts to different environmental requirements. Understanding the characteristics, technical parameters, and application scenarios of different door types will help companies improve operational efficiency while also reducing costs and increasing overall business competitiveness.

Through the introduction of this article, we hope to help enterprises make an informed decision on the most suitable door body for your distribution centre. And improve the overall efficiency of warehousing and logistics.

FAQ

Q1:How to choose the right warehouse door?

A1: Choose the right type of door according to specific needs, such as working frequency, temperature control requirements, space size and security needs. For example, high-frequency opening and closing warehouses should choose high-speed rolling doors. And cold chain warehouses should choose doors with good heat preservation effect.

Q2:What are the technical parameters to be concerned when choosing distribution centre doors?

A2:Mainly focus on the opening and closing speed, sealing performance, wind resistance, temperature control performance and durability, etc.. To ensure that the door body can meet the specific scene requirements.

Q3: Does SEPPES door body products support customisation?

A3: Yes, SEPPES supports the customisation of door body size, colour, material and intelligent system to meet the needs of different customers.

Brand Recommendation

SEPPES: Focus on efficient and safe industrial door solutions, widely used in distribution centres, warehousing, logistics and other industries.

Hörmann: a well-known brand in Germany, providing high-quality industrial doors for a wide range of application scenarios.

ASSA ABLOY: A leading global supplier of door solutions. Providing a full range of services and technical support, adapting to the needs of multiple industries.