Introduction to Industrial Door Hardware

Industrial door hardware plays a vital role in the functionality, durability, and safety of industrial doors. From door hinges and locks to tracks and actuators, each hardware component has a direct impact on the smooth operation and longevity of the door system. Understanding the different types of industrial door hardware and their applications is essential for organizations to choose the best door solution.

In this guide, we’ll provide an in-depth analysis of the types of industrial door hardware, their functions, application scenarios, maintenance methods, and lifespan. Additionally, we will look at how to choose the right hardware for different industrial door types, usage requirements, and geographic areas.

Types of Industrial Door Hardware

There are various types of industrial door hardware, each adapted to different door needs. The following are the main types of industrial door hardware:

Door Hinges

Description:

Door hinges are an important part of a swinging door, enabling the door to open and close smoothly. Depending on the weight and function of the door, hinges come in different sizes and materials.

Category:

Continuous hinges: for heavy-duty doors that require weight bearing.

Hinge hinges: hinges used for standard light and medium industrial doors.

Heavy duty hinges: for doors used in high frequency, usually installed in workshops or large factories.

Place of application:

For manual or heavy-duty swinging doors, typically found in warehouses, factories, and high-traffic facilities.

Track and Roller

Description:

Tracks and rollers are the core components of sliding and up-and-over doors, ensuring smooth opening and closing of the door. The track system supports the weight of the door, while the rollers allow the door to move smoothly.

Category:

Aluminum track: lightweight and corrosion-resistant for smaller doors or low-traffic areas.

Steel Track: Used for large and heavy doors to provide better support and stability.

Polymer Rollers: typically used in quiet environments, providing smoother and quieter operation.

Application Locations:

For sliding, up-and-over, and roll-up doors, it is widely used in loading bays, storage units, and industrial warehouses.

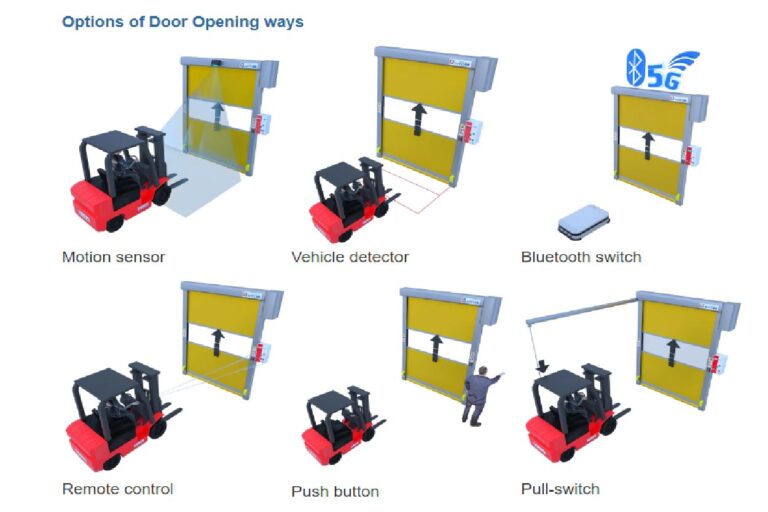

Drives and Motors

Description:

Industrial door drives and motors are used to automate industrial doors, providing the necessary power to make the doors open and close efficiently.

Category:

Electric motors: for automated doors used at high frequencies, such as high-speed rolling doors or fast-opening garage doors.

Hydraulic actuators: for heavy doors that require a large lifting capacity, commonly used in industrial loading docks.

Chain actuators: Commonly used for sliding doors, providing a cost-effective solution for medium-duty use.

Application Locations:

Suitable for high-traffic areas, automatic doors, and heavy-duty industrial doors such as high-speed roller shutters and high-security gates.

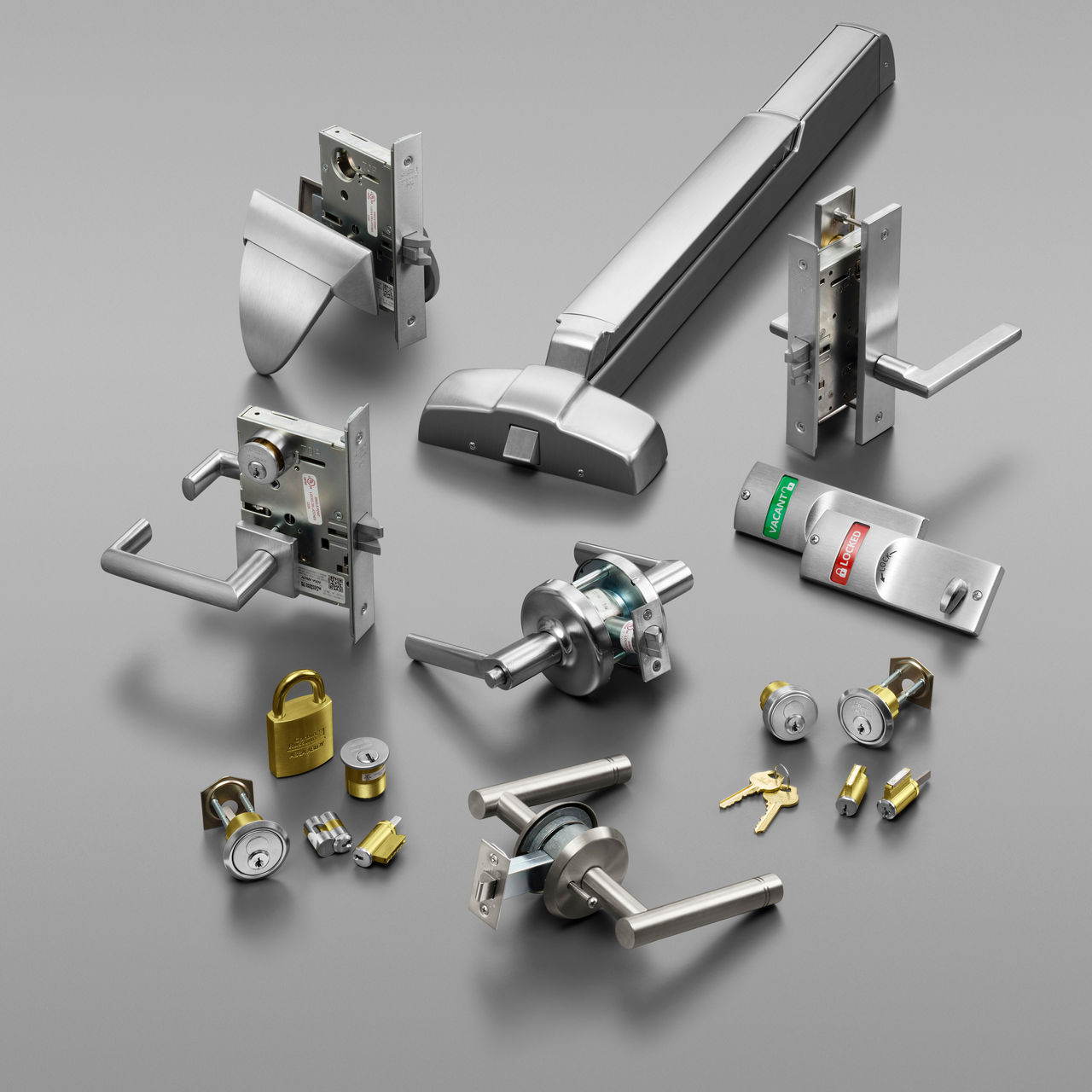

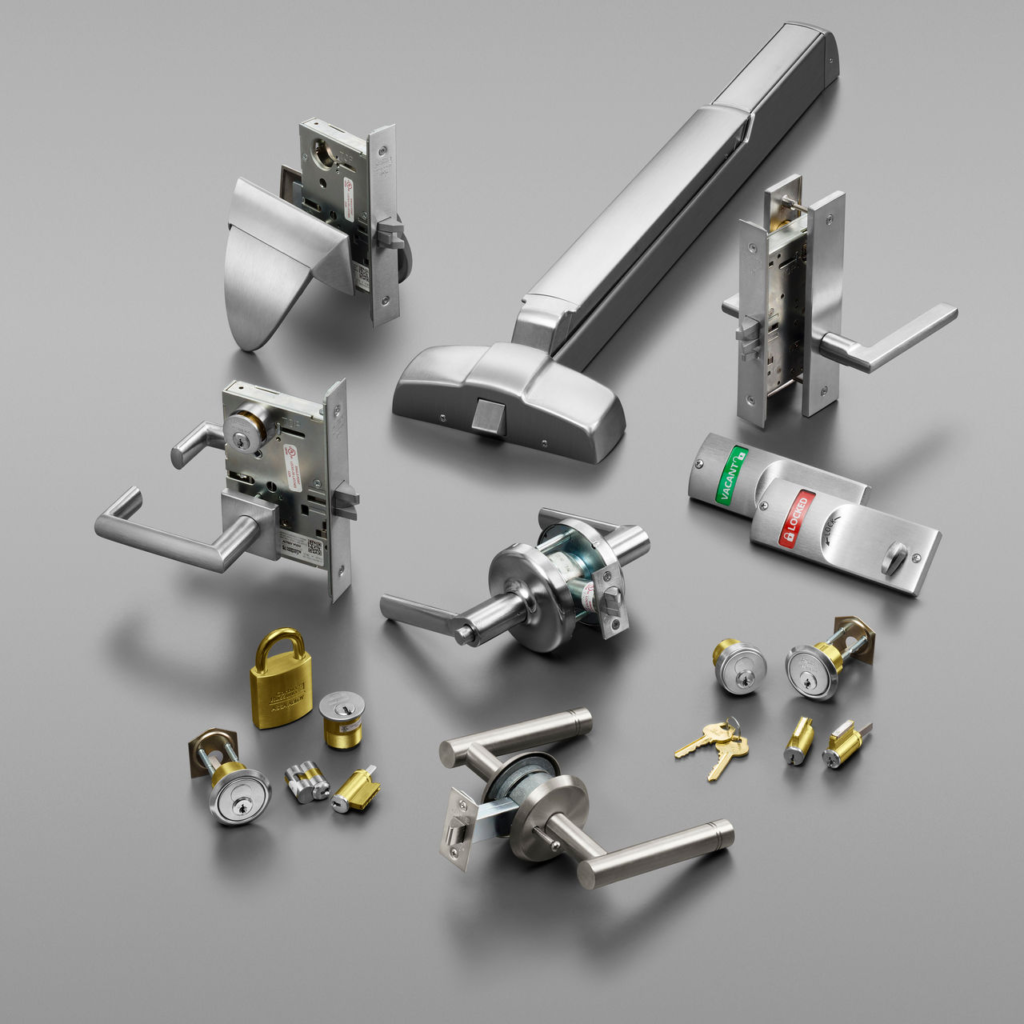

Locks and Latches

Description:

Locks and latches are used to secure industrial doors, prevent unauthorized access, and enhance protection.

Category:

Deadbolt: provides strong security and is commonly used on fire doors.

Padlock: a convenient locking device, often used for temporary doors.

Magnetic locks: used in high security environments such as cleanrooms or sensitive areas.

Place of application:

Mainly used for swing doors, fire doors and security doors, such as pharmaceutical factories, electronic manufacturing plants and logistics centers.

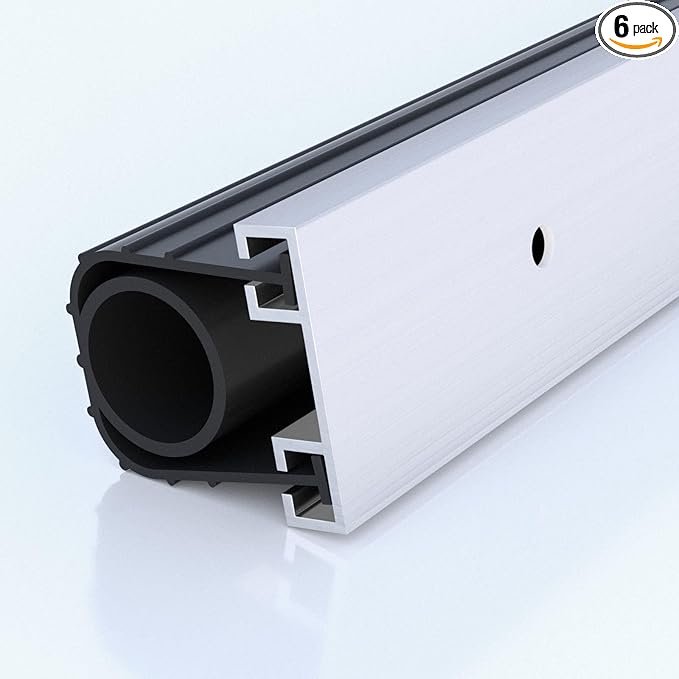

Seals and weatherstripping

Description:

Seals and weatherstripping help keep air, moisture, dust, and pests out of facilities. They are especially important in temperature-controlled environments.

Category:

PVC Seal Strips: commonly used on lightweight doors to provide basic protection from drafts and dust.

Rubber seals: Used in areas that require stronger protection, commonly found in cold storage.

Magnetic seals: commonly used in high-speed doors, providing higher sealing performance.

Place of application:

Used in cold storage facilities, high-speed doors, and environments requiring airtightness, such as cleanrooms and food processing plants.

Functions of Industrial Door Hardware

Industrial door hardware has several key functions that directly affect the efficiency, safety, and longevity of the door. Below are the key functions of industrial door accessories:

Enhances door functionality

Properly installed hardware ensures that the door will function as intended-smooth opening and closing, good sealing, and reduced friction. Components like tracks and rollers or motors are critical to the door’s smooth operation.

Enhanced Security and Protection

Industrial door hardware provides the necessary security features for the door body, with locks, latches, and security barriers ensuring that the door protects industrial facilities from unauthorized entry.

Increased durability and longevity

High-quality hardware significantly improves the lifespan of a door. Materials like stainless steel and galvanized steel are widely used in industrial door hardware to withstand heavy use and environmental challenges.

Improved Energy Efficiency

Seals, weatherstripping, and insulation play a critical role in improving the energy efficiency of a door. Seals in insulated high-speed or roll-up doors help maintain the temperature inside the building and reduce energy consumption.

How to Maintain Industrial Door Hardware

Proper maintenance ensures the long-term operation of industrial door hardware. Here are the main ways to maintain your industrial door hardware:

Regular Inspection

Regularly inspect door hardware for signs of wear and tear, checking components such as hinges, tracks, seals, and motors. Pay special attention to the alignment of the door to ensure that it opens and closes smoothly.

Lubrication

Regularly lubricate rollers and hinges to reduce friction and prevent premature wear. Use the proper lubricant to ensure that you don’t damage the materials of the hardware.

Cleaning

Clean tracks, seals, and sensors regularly to keep the door running smoothly. Dust, dirt, and debris may affect the long-term use of the door.

Specialized Maintenance

For electric drive systems and hydraulic operating systems, it is recommended to have them inspected and maintained by a professional regularly. These components require specialized tools and techniques to ensure their long-term stable operation.

Longevity and Quality of Industrial Door Hardware

The longevity of industrial door hardware depends on several factors, including:

Quality of materials: stainless steel and galvanized steel are more durable than cheaper materials.

Frequency of use: Doors used at high frequencies, such as high-speed roll-up doors, require stronger hardware support.

Environmental conditions: Door bodies used in harsh environments (e.g., high temperatures, moisture or dust) can accelerate wear and tear.

Typically, industrial door hardware has a lifespan of 5 to 15 years, but components like motors and seals may need to be replaced more frequently.

Industrial door hardware in different countries and regions

The use of industrial door accessories varies depending on environmental conditions, industry needs, and regional regulations. Here are some common regional applications:

North America

In North America, the demand for industrial door hardware comes mainly from the automotive manufacturing, logistics, and cold storage industries. Facilities like cold storage require highly insulated doors with specialized hardware to ensure temperature control.

Europe

In Europe, industrial doors are widely used in automotive manufacturing plants, warehouses, and food processing plants, among others. High-velocity doors and door bodies with enhanced sealing are particularly important in the pharmaceutical industry and cleanrooms.

Asia Pacific

Countries such as China, India, and Australia are experiencing rapid growth in logistics and manufacturing. There is an increased demand for high-security doors and automated doors to improve safety and operational efficiency, especially in high-precision industries such as electronics factories and pharmaceutical plants.

Conclusion

Choosing the right industrial door hardware is critical to ensuring the safety, functionality, and longevity of your doors. By understanding the different types of hardware and their applicable functions, application scenarios, and maintenance requirements, organizations can better select the hardware solution that fits their needs.

Proper installation and regular maintenance can significantly extend the life of an industrial door, reduce repair costs, and optimize production processes. When selecting hardware, decisions need to be made based on frequency of use, environmental conditions, and budget to ensure the stability and efficiency of the door system.

FAQ: Frequently Asked Questions

1. What is industrial door hardware?

Industrial door hardware includes all the components used to ensure that an industrial door opens, closes, locks, and seals properly, such as hinges, locks, tracks, drive systems, and more.

2. How do I choose the best industrial door hardware?

When choosing, you need to consider the type of door, the frequency of use, the working environment, and the security needs, such as the need for fire protection or thermal insulation of the area, to choose the appropriate door and hardware.

3. How long does hardware last?

Door hardware typically has a lifespan of 5 to 15 years, depending on the frequency of use, materials, and environmental conditions.

4. How do I maintain my industrial door hardware?

Regularly inspect, lubricate, and clean all moving parts, keep motors and sensors in good operating condition, and call in a professional for maintenance when necessary.

5. Is the installation of industrial door accessories demanding?

Depending on the type of door and usage requirements, some hardware, such as an electric motor and hydraulic drive system, may require professional installation to ensure stable and efficient operation of the system.