The pharmaceutical industry relies heavily on efficient conveyor belt systems for the rapid transport of crucial products, such as pharmaceutical capsules. To ensure a clean and sterile environment while maximizing productivity, the integration of high-speed shutter doors has become essential. This article delves into the three key attributes of high speed shutter door that significantly benefit pharmaceutical conveyor belt operations.

Three Key Attributes Of High Speed Shutter Door In Pharmaceutical Conveyor Belt

Intelligent linkage opening: Seamless Integration with Conveyor Belts

High speed shutter doors, equipped with state-of-the-art sensors including linkage and radar systems, offer unparalleled compatibility with conveyor belts. These doors automatically respond to product presence, swiftly opening as capsules approach and closing promptly after passage. This linked lifting mechanism ensures smooth transportation, minimizing downtime and optimizing workflow efficiency.

High-Frequency Operation: Uninterrupted Productivity

With the ability to operate more than 800 times a day, high speed door facilitates round-the-clock pharmaceutical production. The speed, adjustable from 0.8 to 1.5m/s, allows for swift and efficient product flow. Customizable control systems further enhance operational stability, significantly reducing time wastage. This high-frequency operation ensures uninterrupted productivity, a crucial requirement in pharmaceutical manufacturing.

Superior Sealing: Maintaining Sterility and Cleanliness

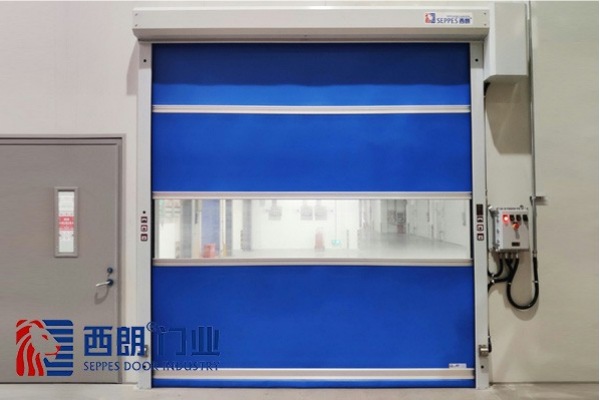

The door curtain and guide rail employ a double-row zipper structure, ensuring robust sealing. This innovative design effectively prevents dust and insects, maintains constant temperature and humidity levels, and facilitates rapid isolation. Achieving a cleanliness level of D according to GMP standards, these doors play a pivotal role in maintaining a sterile production environment.

Customization for Varied Pharmaceutical Requirements

In addition to the fundamental features, high speed shutter doors can be customized to meet specific needs. For pharmaceutical facilities requiring cold storage, these doors possess anti-static, waterproof, and moisture-proof properties. Furthermore, they are resistant to rust and corrosion, ensuring longevity and reliable performance even in challenging environments.

In conclusion, high speed shutter doors have revolutionized pharmaceutical production by seamlessly integrating with conveyor belts. Their linked lifting mechanism, high-frequency operation, superior sealing, and customization options cater to the diverse needs of the industry. When investing in high speed shutter doors, choosing a trusted brand like SEPPES ensures unparalleled quality and performance, enabling pharmaceutical manufacturers to maintain optimal cleanliness, efficiency, and productivity. Their high-quality products are trusted by Fortune 500 companies such as IKEA and AkzoNobel.