With the accelerated modernisation of Saudi Arabia’s industry, especially in the logistics industry, new energy plants and large-scale warehousing facilities, the need for efficient and safe loading and unloading of goods has become increasingly important. Loading Dock Equipment has become an indispensable key equipment for industrial sites due to its excellent performance in improving loading and unloading efficiency and ensuring cargo safety. Especially in the face of extreme weather conditions in Saudi Arabia, the role of loading dock equipment is more prominent. In this article, we will discuss the various products and technical parameters of loading and unloading platforms, and provide detailed installation and purchasing guides to help companies optimise their logistics operations and improve overall

What is Loading Dock Equipment?

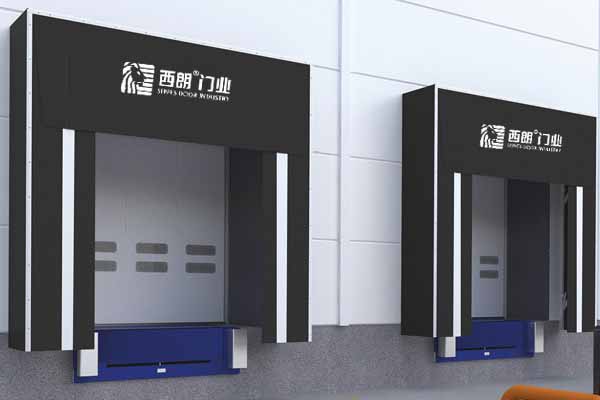

Loading Dock Equipment is a vital logistics tool in industry, especially in modern warehousing, transport and production. They ensure a smooth, safe and efficient transfer of goods from transport vehicles (e.g. lorries) to industrial sites (e.g. warehouses, factories). Docking platforms comprise a number of key components, such as the Dock Leveler, Dock Shelter and Sectional Door, which play an important role in the logistics industry, in factory warehouses and in the emerging new energy sector.

Why is loading dock equipment widely used in Saudi Arabia?

Coping with Saudi Arabia’s harsh climatic conditions

Saudi Arabia has extreme climatic conditions, with year-round high temperatures and frequent sandstorms posing a serious challenge to industrial logistics sites. In these extreme environments. The loading and unloading of goods can be easily disturbed by external factors, resulting in damage to goods and a reduction in logistics efficiency. Dock Shelters and sectional doors in loading dock equipment, on the other hand, prevent the external environment from affecting goods and workers through their excellent sealing properties, ensuring that cargo loading and unloading takes place in a safe and controlled environment.

Improve loading and unloading efficiency, save time and cost

The automated and intelligent design of the loading and unloading platform equipment greatly improves the efficiency of cargo loading and unloading. The loading platform is able to automatically adjust the height and bridge the gap between the lorry and the loading/unloading port, enabling a smooth transfer of goods. This technology reduces manual intervention in cargo handling, improves work efficiency and reduces operating time. For places with frequent logistics and large amount of cargo flow, the efficient operation of loading and unloading platform equipment can save a lot of costs and reduce the operating expenses of enterprises.

Guarantee safety and reduce cargo loss

Safety is the most critical factor in the process of cargo loading and unloading. Loading dock equipment ensures the safety of operation through intelligent safety systems. For example, the industrial lifting door is equipped with fast opening and closing function and safety light curtain and other protection devices. Which can effectively prevent the goods from falling or the personnel from being injured. The door seal also effectively blocks dust and moisture from entering the loading and unloading area, preventing damage to goods caused by environmental factors.

Key products and technical parameters in the equipment

1. Dock Leveler

The dock leveler is an important piece of equipment in the process of loading and unloading goods and is usually used to connect the difference in height between the lorry and the warehouse to ensure smooth and safe loading and unloading of goods. The following are some key technical parameters of the dock leveler:

Load capacity: Maximum load capacity is up to 15 tonnes, which is suitable for heavy cargo and frequent use scenarios.

Size: The standard size is 2000mm x 2500mm, with options for customization to suit different types of loading and unloading sites.

Hydraulic system: Built-in hydraulic lifting system can automatically adjust the height of the loading platform to ensure smooth loading and unloading of goods.

Safety performance: Equipped with non-slip surface treatment and safety locking system to ensure the operation safety during the loading and unloading process.

The dock leveler is usually used in logistics centres, large warehouses and factories, providing a stable and safe bridge for the transfer of goods between trucks and warehouses.

2. Dock Shelter

Dock Shelter is a key device to protect cargo and personnel during the loading and unloading process. It prevents the external environment from affecting the loading and unloading process by sealing the space between the lorry and the loading/unloading port. In Saudi Arabia. Where the high temperatures and sandy winds common in the country place a high demand on the protection of cargoes. The door sealing equipment is particularly important. The following are the main technical features of door seals:

Material: High Density Polyethylene (HDPE) with tear and abrasion resistance for long term use.

Adaptive adjustment: The door seal automatically adjusts its size to fit different types of lorries, ensuring a perfect fit and minimizing the penetration of outside air.

Sealing performance: Multi-layer structure design ensures excellent sealing effect, preventing heat loss and dust entry.

Door sealing equipment is widely used in a number of industries in Saudi Arabia. Especially in logistics warehousing and high temperature environments. Helping companies to improve loading and unloading efficiency while protecting goods from external weather.

3.Sectional Door

Typically used in large-scale factories, warehouses and logistics centres, the Sectional Door is designed for fast opening and closing, excellent sealing performance and the ability to cope with frequent opening and closing operations. The following are the key technical parameters of industrial liftgate:

Door material: High strength polyurethane filling, thickness of 40mm, with excellent thermal insulation and heat insulation performance.

Opening and closing speed: The opening speed can reach 0.6 metres per second, which is suitable for high-frequency operations and ensures smooth logistics.

Sealing system: multi-layer sealing design, can effectively isolate the external air, reduce energy loss, especially suitable for temperature-sensitive storage facilities.

Wind resistance: with strong wind resistance. It is suitable for the windy environment in Saudi Arabia and ensures the long-term stability of the door body.

Industrial lifting doors are widely used in new energy factories and logistics centres in Saudi Arabia. Which can guarantee stable temperatures inside and outside the workshop, reduce energy loss and improve safety at the same time.

| Product Type | Core Functions | Applicable Scenarios | Technical Parameters | Recommended Brands | Additional Functions |

| Dock Leveler | Connects the height difference between the truck and the warehouse to ensure smooth loading and unloading of goods. | Logistics centers, large warehouses, factories | – Load: 15 tons- Dimension: 2000mm×2500mm (can be customized)- Hydraulic lifting system- Anti-slip surface + safety lock | SEPPES, Hörmann, Rite-Hite | Automatic height adjustment, high temperature resistant hydraulic fluid |

| Dock Shelter | Seal the gap between the truck and the loading/unloading port to isolate the outside environment. | High-temperature warehousing, sandstorm-prone areas | – Material: high density polyethylene (HDPE)- Adaptive size adjustment- Multi-layer sealing structure | SEPPES, Hörmann, Rite-Hite | UV resistant coating, sand filter |

| Sectional Door | Quick opening and closing, efficient sealing, maintaining temperature-controlled indoor environment. | New energy factories, cold chain warehouses | – Material: 40mm polyurethane filling- Switching speed: 0.6m/s- Multi-layer sealing + wind pressure resistance 800Pa | SEPPES, Hörmann, Rite-Hite | Emergency manual unlocking device |

Installation and Purchase Guide for Loading Dock Equipment

1. Installation guidelines

There are a number of factors to consider when installing loading platforms at industrial sites in Saudi Arabia. Firstly, the site environment, loading platforms, door seals, and lifting gates should be customized to fit the size and layout of the actual loading and unloading area. Secondly, the frequency of use of the equipment. For high-frequency operations, it is recommended to choose equipment with high durability and quick response capability. Climatic factors should also be taken into consideration. As the extreme weather in Saudi Arabia places high demands on the durability and sealing performance of the equipment.

2. Purchasing recommendations

When purchasing loading platform equipment, the following points should be considered:

Carrying capacity: Choose the right carrying capacity according to the weight of the goods to ensure that the equipment can operate safely for a long time.

Durability of equipment: Choose equipment that has undergone rigorous quality testing, especially durable materials that can withstand the harsh climate conditions in Saudi Arabia.

Level of automation: Modern logistics equipment should have automation features to improve loading and unloading efficiency and reduce manual intervention.

After-sales service: Long-term maintenance of the equipment is also very critical. You should choose a brand that offers excellent after-sales service to ensure timely resolution of any issues that arise during use.

The future of loading dock equipment

With the modernisation of global industry, loading and unloading platform equipment is also progressing. In the future, loading and unloading platform equipment will make greater breakthroughs in intelligence and automation. The application of Internet of Things (IoT) technology will enable the equipment to monitor the operation status in real time. Prevent failures in advance, and improve the overall efficiency and safety of the equipment.

In addition, with the continued development of the Saudi Arabian industry. Especially the rapid expansion of the new energy and logistics industries. The market demand for loading and unloading platform equipment will grow significantly. Through more environmentally friendly design and efficient operating procedures. The loading platform equipment will help companies to further optimise the production chain and achieve more efficient industrial logistics operations.

Recommended brands of related loading dock equipment

1. SEPPES

Brand Features: SEPPES is known for its high-quality loading platforms, door seals and industrial lifting gates, which are particularly suited to extreme climatic conditions. Its equipment performs well in Saudi Arabia and other hot and sandy areas with strong durability and safety.

Scenarios: logistics centres, new energy plants, manufacturing plant warehouses

Recommended products: Hydraulic loading platforms, door seals with high sealing performance. Industrial lifting doors for environments that require frequent loading and unloading operations.

2. Hormann

Brand features: Hormann is a global leading supplier of industrial doors and loading platforms. Focusing on high-quality industrial doors and door seals, providing superior safety and energy-efficiency performance. Hormann’s loading platforms are suitable for long-term use in high-temperature environments.

Scenarios: logistics parks, cold chain warehousing, large-scale factories

Recommended products: wind-resistant industrial lifting doors, fast rolling doors, automated loading and unloading platforms.

3. Rite-Hite

Brand features: Rite-Hite focuses on high-performance safety solutions, especially safe and efficient operations in loading and unloading areas. Its equipment emphasises operational safety and energy efficiency, and is ideally suited to meet the challenges of Saudi Arabia’s harsh climate.

Scenarios: food processing plants, logistics centres, industrial production plants

Recommended products: High-performance lifting platforms, door seals and industrial safety doors.

FAQ

What industries are loading dock equipment suitable for?

Loading and unloading platforms are widely used in the logistics industry, new energy factories, food processing plants. Warehousing facilities and other places where frequent loading and unloading of goods is required.

How to ensure the safety of loading and unloading platforms?

Modern loading and unloading platforms are equipped with a variety of safety devices. Such as non-slip surface treatment, hydraulic locking system and safety light curtains, etc., which can effectively reduce the potential safety hazards in operation.

What do I need to pay attention to in the daily maintenance of the equipment?

Regularly check the hydraulic system, seals and safety devices to ensure smooth operation of the equipment. The extreme climate in Saudi Arabia may affect the life of the equipment, regular cleaning and lubrication is recommended.

How to choose the right dock equipment?

Choose the right equipment according to the frequency of loading and unloading. The weight of the goods and the layout of the site. For high-frequency operation sites.

It is recommended to choose equipment with a high level of automation and durability to ensure stable, long-term operation.

Summary

Loading and unloading platform equipment plays an irreplaceable role in industrial sites in Saudi Arabia. By choosing the right loading and unloading platforms. Door shelters and industrial sectional doors, companies can dramatically improve the efficiency of cargo handling, reduce costs and ensure cargo safety. In the future, with the further development of automation technology. Loading platforms will continue to play an important role in modernising industrial logistics in Saudi Arabia and globally!