In industrial and commercial settings, sectional door panels are a key component in building efficient, robust and energy-saving door systems. Widely used in environments such as warehouses, production halls, cold rooms, etc., these panels provide excellent security, sealing and space utilisation. In this article, we will introduce the different types of sectional door panels, their application scenarios, technical specifications and pricing considerations to help you choose the most suitable door system for your needs.

What are Sectional Door Panels?

Sectional door panels are the individual components that make up the body of a sectional door. They are usually connected by multiple hinges and can be opened vertically and rolled into the top track. Depending on the requirements, these door panels can be made of different materials (e.g. steel, aluminium, wood) and in different thicknesses to meet the requirements of various industrial and commercial applications.

Types of Sectional Door Panels

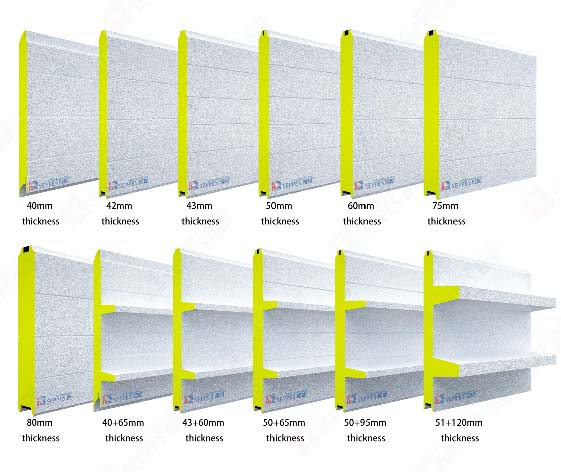

Insulated Sectional Door Panels

Material: Usually a steel outer layer with polyurethane foam or polystyrene foam in the centre, providing good thermal insulation.

Thickness: usually between 35mm and 60mm, selected according to the different needs of thermal insulation.

Application Scenario: Suitable for cold storage, temperature-controlled warehouses and other environments where temperature needs to be maintained.

Non-Insulated Sectional Door Panels

Material: Made of sturdy steel or aluminium with corrosion-resistant material coated on the outer surface.

Thickness: Generally 0.4mm to 0.6mm.

Application Scenario: Suitable for environments that do not require strict temperature control, such as general warehouses or freight aisles.

Aluminium Sectional Door Panels

Material: Made of aluminium alloy with high corrosion resistance, suitable for wet environments.

Thickness: Approximately 0.8mm to 1.5mm.

Application Scenario: Widely used in places that need to resist corrosion, such as seaside warehouses and garages.

Fire-Rated Sectional Door Panels

Material: Made of special fireproof material, such as mineral-filled steel plate, with high fire resistance.

Thickness: usually between 45mm and 70mm.

Application Scenario: Suitable for places with strict fire protection requirements, such as chemical warehouses and factories.

Technical specifications for Sectional Door Panels

Door Panel Thickness

Uninsulated Door Panels: Typical thicknesses are 0.4mm to 0.6mm.

Insulated Door Panels: Typically 35mm to 60mm thick, the greater the thickness, the greater the insulation.

Material

Steel: the most commonly used material, with high strength and good safety.

Aluminium: lightweight and corrosion resistant, suitable for wet or corrosive environments.

Timber: used in residential environments or where there is a specific aesthetic requirement.

Surface Coatings

Polyester coated steel: corrosion and abrasion resistant, suitable for most environments.

Hot-dip galvanised steel: provides additional protection against rust and corrosion.

Powder coated: available in a wide range of colour options, with a smooth and durable surface.

Insulation materials

Polystyrene : lower cost and suitable for general insulation needs.

Polyurethane : offers higher thermal resistance and is suitable for locations with high insulation requirements.

Technical specifications for Sectional Door Panels

Door Panel Thickness

Uninsulated Door Panels: Typical thicknesses are 0.4mm to 0.6mm.

Insulated Door Panels: Typically 35mm to 60mm thick, the greater the thickness, the greater the insulation.

Material

Steel: the most commonly used material, with high strength and good safety.

Aluminium: lightweight and corrosion resistant, suitable for wet or corrosive environments.

Timber: used in residential environments or where there is a specific aesthetic requirement.

Surface Coatings

Polyester coated steel: corrosion and abrasion resistant, suitable for most environments.

Hot-dip galvanised steel: provides additional protection against rust and corrosion.

Powder coated: available in a wide range of colour options, with a smooth and durable surface.

Insulation materials

Polystyrene : lower cost and suitable for general insulation needs.

Polyurethane : offers higher thermal resistance and is suitable for locations with high insulation requirements.

Application Scenarios for Sectional Door Panels

Warehouse and factory environments

Due to their high strength and safety, sectional door panel are widely used in warehouses and production plants. Especially insulated door panels, they control the internal temperature efficiently and save energy.

Cold storage and freezing facilities

Insulated door panels are ideal for cold stores, freezers and refrigerator warehouses. They maintain a constant low temperature and help reduce energy consumption.

Fire-protected areas

Fire-rated sectional door panels are widely used in areas that require strict fire protection, such as chemical storage areas and industrial facilities.

Retail and commercial spaces

Aluminium door panels are commonly used in shopping malls, supermarkets, catering and retail outlets due to their aesthetics and corrosion resistance.

Private Garages

For residential environments, wood or non-insulated steel door panels are commonly used in private garages to provide security and aesthetics.

Why Choose Sectional Door Panels?

Energy efficiency

Insulated door panels reduce energy consumption by insulating against external heat or cold air flow and reducing temperature fluctuations in the room.

Security and Durability

Steel and aluminium materials provide excellent security and resistance to vandalism, ensuring that the door can withstand high-frequency use for extended periods of time.

Space-saving design

Since sectional doors rise vertically when opened, they make better use of space, especially in limited space environments.

Customised options

Sectional door panels can be customised to meet specific needs, including size, colour and material to meet different customer requirements.

Price Considerations

Sectional door panels vary in price depending on material, thickness, customisation options and features.

Non-Insulated Door Panels: Generally less expensive and suitable for projects with a limited budget, priced between $500 and $1500.

Insulated Door Panels: Provide better insulation and are more expensive, usually ranging from $1,000 to $3,000.

Fire-rated door panels: typically cost between $2,000 and $5,000, depending on the fire rating and specifications.

Price fluctuations are also affected by door size, material and customisation requirements.

Conclusion

Sectional door panels are an integral part of a wide range of industrial, commercial and residential applications. Whether in warehouses, cold rooms, factories, or fire zones, these door panels provide excellent performance and long-term durability. By choosing the right materials, specifications and customisation options, users can achieve a better experience and energy efficiency for their needs.

FAQ

Q1: What are Sectional Door Panel?

A1: Sectional Door Panel are part of Sectional Doors, which usually consist of multiple panels that are hinged to open vertically and stowed in the top track. They are widely used in industrial, commercial and residential environments for security, sealing and insulation.

Q2: What scenarios are Sectional Door Panels used in?

A2: Industrial sectional door Panel are suitable for a wide range of scenarios, including warehouses, factories, cold rooms, fire zones and commercial spaces. Depending on the scenario, different materials and insulation properties can be selected, for example, cold storage requires high insulation properties, while factories and warehouses focus more on durability and wind resistance.

Q3:What factors do I need to pay attention to when choosing Sectional Door Panels?

A3:When choosing Sectional Door Panel, firstly, you need to consider the needs of the usage scenarios, such as whether you need thermal insulation, fire protection, wind resistance and so on. Secondly, choose the right thickness and material according to the size, material and performance requirements of the door body. For cold storage and other environments that require temperature control, it is recommended to choose door panels with strong thermal insulation effect.

Q4: What brands are recommended for Sectional Door Panels?

A4:Recommended brands include SEPPES, Hörmann, ASSA ABLOY, etc. These brands have a good reputation and a wide range of applications worldwide, and are able to provide high-quality, customised Sectional Door Panel to meet different industrial and commercial needs.