Industrial doors play a vital role in a variety of commercial and industrial locations, not only in facilitating the movement of goods and equipment, but also in maintaining safety, saving energy and improving operational efficiency. Among the various types of industrial doors, doors with sectional door types stand out due to their versatility, efficiency and reliability. This article explores the importance of sectional doors in industrial applications and provides a comprehensive guide to selecting the best sectional door for your specific needs.

Understanding sectional door

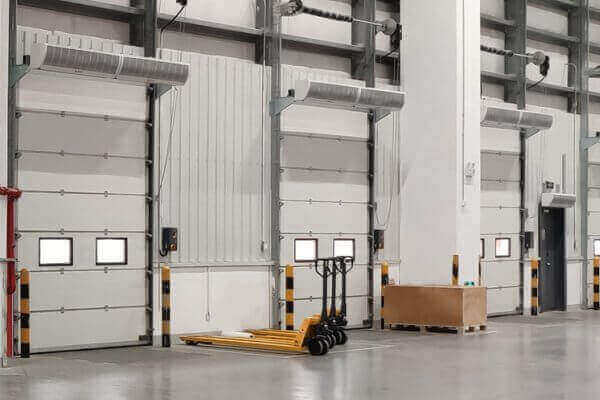

Sectional doors consist of horizontally hinged panels that open and close vertically along a track. This design maximizes space inside and outside while providing superior insulation and security. Sectional doors can be made from a variety of materials including steel, aluminum, and composites. Each offering unique advantages in terms of durability, aesthetics, and cost-effectiveness.

Advantages of sectional door

Space Efficiency: Sectional doors can open vertically, allowing vehicles. And equipment to approach the door without impeding its operation, making them ideal for facilities with limited space. For example, SEPPES Doors’ sectional overhead door has four lifting options, standard lift, raised lift, vertical lift, and low lift, which are multi-faceted to meet the needs of the customer.

Insulation and Energy Saving: The sealing effect created by the sectional door panels reduces heat loss. And prevents drafts, helping to save energy and keep the room temperature stable.

Security: Sectional doors are equipped with a robust locking mechanism and can be reinforced with additional security features. Such as electronic access control systems and impact-resistant materials.

Customization Options: With a range of options spanning from sizes and materials to colors and window configurations. Sectional doors provide a highly customizable solution to suit the aesthetic and functional needs of any industrial environment.

Choosing the Right Sectional Door

Choosing the best sectional door involves considering several factors to meet specific needs:

Size and dimensions: Accurately measure the size of the opening to ensure the sectional door fits perfectly.

Material selection: When assessing the durability, insulation, and maintenance requirements of different materials, it’s crucial to select the most appropriate option.

Insulation Requirements: Evaluate the level of insulation needed based on the climate and expected level of use of the facility.

Security features: Determine security requirements and select sectional doors with appropriate locking mechanisms and reinforcements.

Operating Mechanisms: Choose between manual, motorized, or remote-controlled sectional doors based on convenience and operational needs.

Budget considerations: Balance upfront costs with long-term savings and benefits to make informed investment decisions.

Case Studies and Best Practices

Warehouse Applications: Sectional doors with high insulation and fast opening/closing speeds improve efficiency and temperature control in warehouses.

Cold Storage Facilities: Insulated sectional doors with tight seals are critical to maintaining a temperature controlled environment in cold storage facilities.

Manufacturing Facilities: Sectional doors with robust security features and customizable configurations ensure safety in manufacturing facilities.

Retail and Commercial Spaces: Sectional doors with aesthetic appeal and visibility options enhance the appearance of retail stores and provide easy access for customers.

Sectional door represent a versatile and efficient solution to industrial door needs, offering the perfect combination of space efficiency, insulation, security and customization options. By carefully evaluating specific needs and considering factors. Such as size, materials, insulation, security, operating mechanisms and budget, businesses can select the optimal sectional door to unlock the full potential of their industrial facility.