Industrial doors play a vital role in modern industrial production, its function is not only limited to provide entrance and exit, more importantly. It is able to protect the safety of the production area, improve production efficiency and energy saving. Among many industrial doors, aluminum alloy rolling door has been widely used in the industrial field due to its advantages of lightweight, corrosion resistance, and aesthetics. This article will be the ultimate guide to efficient industrial aluminum alloy rolling doors in terms of design, installation, maintenance and application, aiming to help industrial enterprises make full use of the potential of industrial doors to achieve efficient operation of production.

Choosing to design an efficient industrial aluminum rolling door

Understanding functional requirements

Determine the primary function of the industrial door. Such as whether it needs to open and close frequently, carry large loads, and provide security.

Evaluate the use environment

Consider the special requirements of the installation location of the door body. For example, whether it is necessary to resist wind pressure, corrosion resistance, fire prevention and other properties.

Consider the frequency of use of the door body, and select materials with higher wear resistance and durability as needed.

Determine the size and structure

Determine the size and structure of the door body according to the actual requirements, including height, width, thickness, etc.

Consider the installation space and the surrounding environment. And select the appropriate door opening method (e.g. vertical rising, horizontal sliding) and drive system (manual, electric)

Selection of suitable materials

Aluminum alloy is a commonly used material with the advantages of light weight, high strength. And corrosion resistance, but other materials can also be considered depending on the specific situation.

According to the usage environment and functional requirements of the door body, select the appropriate aluminum alloy material type and thickness to ensure the stability and durability of the door body.

Consider safety and convenience

Ensure that the door body design complies with relevant safety standards, including safety sensors, guards, etc.

Consider the operation convenience of the door body. Choose the appropriate opening method and control system to improve the operation efficiency of the door body and personnel safety.

Consult with professional manufacturers

Communicate with professional industrial door manufacturers or suppliers to get professional advice. And technical support to ensure that you choose an efficient industrial aluminum alloy rolling door that suits your needs. For example, the aluminum alloy rolling door from SEPPES has a one-door-one-code service, no matter where you are, as long as you scan the QR code on the door and contact us, the company will solve the problem for you.

Installation of industrial aluminum alloy rolling door key steps

Site preparation: clean up the construction area to ensure that the installation location is level and stable.

Component installation: install the door body, guide rail, driver and other components according to the design requirements.

Debugging test: carry out the door body operation test, adjust the drive system to ensure smooth opening and closing of the door body.

Safety check: check the safety sensors and guards to ensure that the safety meets the requirements.

The importance and methods of maintaining efficient industrial aluminum alloy rolling door

Regular inspection: Regularly check the door body, guide rail, drive system and other components, and find problems to repair or replace in time.

Cleaning and maintenance: To ensure the smooth operation of the door body, it’s important to regularly clean its surface and lubricate the guide rail.

Safety training: safety training for operators to improve their awareness and skills in the safe operation of the door body.

Industrial aluminum alloy rolling door in the industrial field of application

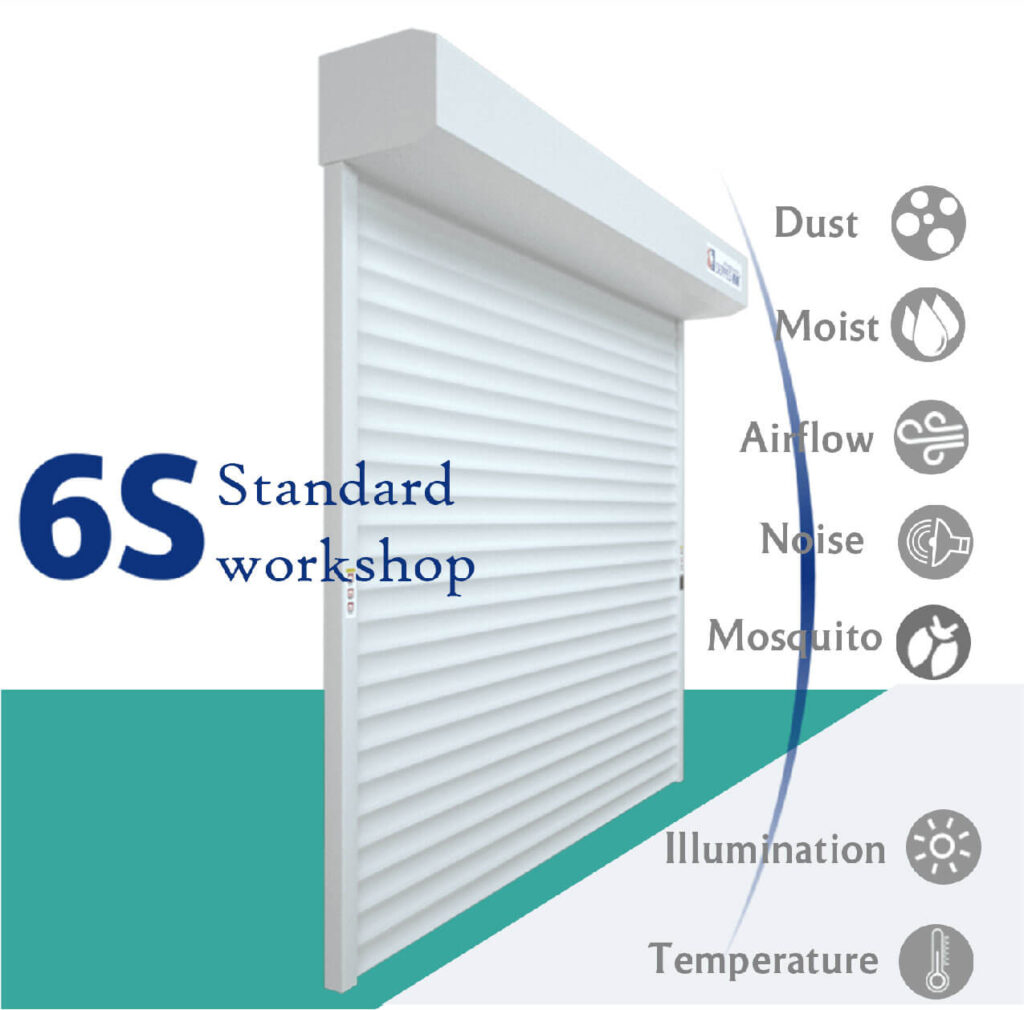

Factory workshop: as the entrance and exit of the workshop, to improve the production efficiency and ensure the safety of the workshop.

Warehouse logistics: Utilized as the entrance and exit of cargo loading and unloading areas and warehouses, this facilitates the acceleration of logistics transportation, thereby optimizing operational efficiency.

Port terminal: As the gateway of the terminal, ensuring convenient cargo loading and unloading as well as vehicle entrance and exit not only enhances port operation efficiency but also streamlines overall logistics processes.

Highly efficient industrial aluminum alloy rolling doors play an important role in industrial production. And their design, installation, maintenance and application are all crucial. With the ultimate guide in this article, industrial companies can better select, use and maintain industrial doors, unlocking their potential and promoting the sustainable development of industrial production.