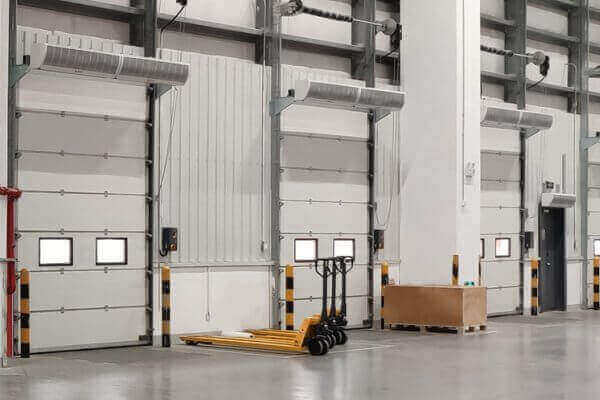

As one of the indispensable equipment in modern industrial production, industrial sectional doors undertake important functions such as cargo entry and exit and vehicle passage. However, due to long-term use and the influence of the external environment, industrial lifting doors may suffer from various failures, causing a lot of inconvenience to production and use. Therefore, it is of great significance to have an in-depth understanding of common industrial sectional door repair.

Analysis of 5 common faults of industrial sectional doors and their causes

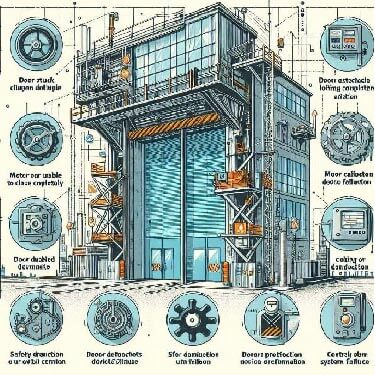

The door becomes stuck or cannot be closed completely.

Dirt on the door rails: After long-term use, dust, grease or other debris may accumulate on the door rails. Causing the door to not slide smoothly, or even get stuck and unable to close completely.

Structural deformation of the door body: The structural deformation of the door body may occur after it experiences external impact or prolonged usage. This deformation can result in poor coordination with the door rails and cause jamming.

Motor cannot start or stop

Power supply failure: The failure of the motor to start may be due to power supply problems. For example power line failure, power switch failure, etc.

Motor damage: Motor damage occurs when the internal parts of the motor sustain damage or severe wear, leading to the inability to start or stop normally.

Safety protection device fails

Sensor failure: Safety protection devices usually use sensors to detect whether the door collides with obstacles. If the sensor is damaged or improperly adjusted, the anti-collision function may fail.

Problems with the connection between the sensor and the control system: If the connection line between the sensor. If the control system becomes disconnected, loose, or has poor contact, it will also cause the anti-collision device to fail.

The door body is damaged or deformed

External impact: External impact can deform or damage the door body when it collides with heavy objects from the outside.

Material aging: After long-term use, the material of the door body may age, corrode, or fatigue, leading to deformation or damage of the door body.

Control system failure

Controller damage: The internal circuit of the controller is damaged . The components are aging, causing the control system to fail to work properly.

Electrical connection problems: There are problems with the connection lines between the control system and motors, sensors and other equipment, such as disconnection, short circuit or poor contact, causing the control system to fail.

Maintenance methods and technologies for industrial sectional doors

Failure prevention and regular maintenance

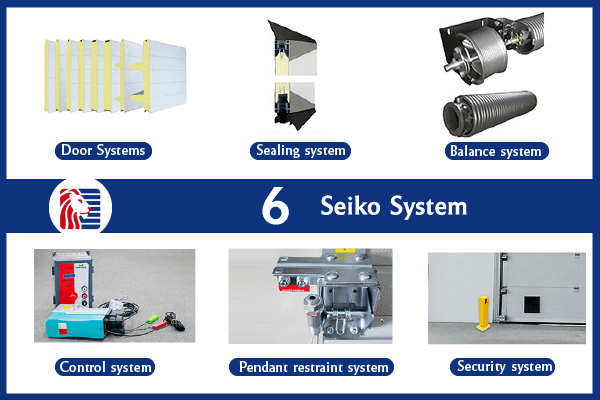

Regular cleaning and lubrication: Regularly clean dust, grease and debris on door rails, pulleys. The hinges and other components to ensure smooth operation of the door. Use appropriate lubricants to lubricate door rails and pulleys to reduce friction.

Regularly check electrical connections: Regularly check whether electrical connections such as power lines, controllers, and sensors. There are loose or worn to ensure good connections and avoid failures caused by short circuits or disconnections.

Check safety devices: Regularly check and test whether safety devices such as anti-collision devices, limit switches, and safety sensors.There are working properly to ensure that the door can stop or run in reverse when encountering obstacles to ensure safe use.

Fault diagnosis and analysis

Use fault diagnosis equipment: Use professional fault diagnosis instruments and equipment to comprehensively detect and diagnose the door’s electrical system, sensors, controllers, etc., and quickly locate faults.

Analysis based on experience: Combined with the experience of maintenance personnel.

In the actual situation, we analyze possible faults and eliminate them to reduce the possibility of faults, enabling us to find solutions more quickly.

Troubleshooting and repair

Replace damaged parts: For damaged or failed parts. such as motors and sensors, replace them with new parts in a timely manner to ensure normal operation of the equipment.

Repair or replace the door body: If the door body becomes deformed or damaged. We will repair or replace it according to the specific situation to ensure the integrity of the door body structure and ensure safety and stability.

Adjustment and calibration: For possible improper adjustments or wrong parameter settings in the control system, make adjustments and calibrations to ensure the normal operation of the control system.

Industrial sectional door maintenance management and optimization suggestions

Establish a complete maintenance management system, including regular maintenance plans and records.

Improve employees’ maintenance and operation skills and strengthen training and learning.

Conduct regular inspections and assessments of industrial lifting doors to identify and resolve problems in a timely manner.

Through the research and summary of common faults and solutions of industrial sectional doors. It can help enterprises and users better maintain and manage industrial lifting doors. And ensure the safety and stability of production and use.

In the future, as technology continues to advance and be applied. We will actively improve and optimize the fault diagnosis and maintenance technology of SEPPES industrial sectional doors.