Many factory workshops need to store large equipment inside, and the equipment cannot be brought in because the entrances and exits are too small. Therefore, workers will reserve a hole in the roof of the workshop to facilitate the lifting in of large equipment. Or due to storage needs, a large pit is reserved on the ground. These two places are for safety reasons and to avoid wind and rain. Doors that are horizontally tight to the ground are required at the opening, and spiral doors are recommended.

What is a Turbo Rapid Spiral Door?

Definition and rationale

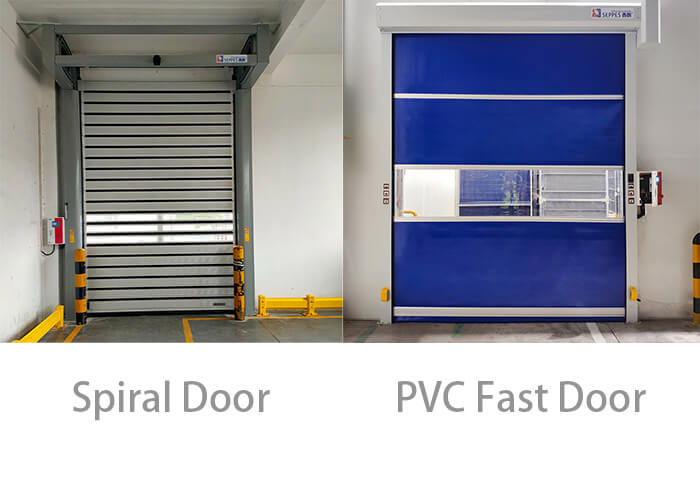

Spiral doors are high speed doors with rigid panels that operate on a spiral track system. Compared to traditional roller shutter doors and sliding doors, the Turbo Rapid Door offers a significant increase in speed and safety. It is designed with a robust door panel and spiral track to ensure smooth operation when the door is opened and closed. Not only does it provide effective insulation from the outside environment, but it also maintains reliable performance in high-frequency use.

Differences with traditional fast doors

Conventional rapid doors typically use flexible materials such as PVC or fabric. Turbo Rapid Doors, on the other hand, use hard metal or composite door panels for greater protection and durability. Spiral Door adopts advanced technology, which is able to realize the horizontal movement effect along the ground instead of the traditional up and down rolling. Its appearance is hard and durable, the internal structure is made of high-density lightweight materials, while equipped with imported servo frequency conversion motor, which makes the door open and close very fast.

How Spiral Doors work ?

Horizontal posting operational mechanism

The Turbo Hard Fast Door enables the door panels to run horizontally against the ground by means of a spiral track system. This design not only reduces friction and noise during operation. It also avoids the tilting and jamming problems that are common with traditional vertically running doors. The precision design of the spiral track ensures the smoothness and accuracy of the door panel when running at high speed. It greatly improves the overall performance of the door.

Key Technologies and Innovations

The core technology of Spiral Door is its spiral track system and high performance motor. The spiral track system keeps the door panel running horizontally when opening and closing through precise angle design. The high-performance motor ensures fast response and stable operation. At the same time, the turbo spiral high speed door is also equipped with advanced sensors and control systems. It is able to monitor the running status of the door in real time to ensure safety and reliability.

Key Benefits of Spiral Doors

Fast response

The opening and closing speed of the rigid fast door is very fast, the speed can be up to Highly customizable0.6-2.35m/s, it can respond quickly to the horizontal switch, and a 5-meter wide doorway can be opened in 3 seconds.

Durable

The door plate adopts double-sided aluminum alloy door plate, thickness of 0.7mm, sandwiched between high-density polyurethane foam material door plate surface using imported plastic powder coating, durability is very strong. […] When the door is running horizontally, there will be no bulging in the middle of the door panel due to gravity.

High security

This spiral fast door has many kinds of safety protection devices such as infrared photoelectricity, light curtain, emergency button and so on. It can react quickly and stop in emergency when the door body is in emergency.

Highly customizable

The spiral door can be customized according to the needs of different places, the size, color, function and so on, can meet the needs of different places for a variety of uses.

Application of Turbo Rapid Doors in different industrial sectors

Logistics & Warehousing

In the field of logistics and warehousing, the fast opening and closing function of the turbo hard fast door can improve the efficiency of goods in and out, maintain the stability of the internal environment, and prevent the entry of dust and foreign objects.

Manufacturing Industries

Production lines in the manufacturing industry demand the highest frequency of door opening and closing and durability. The Turbo Rapid Spiral Doors not only meet these needs, but also ensure product quality by preventing outside contaminants from entering the production area through high sealing performance.

Food & Pharmaceuticals

The food and pharmaceutical industries have very high requirements for environmental hygiene. The dustproof, insect-proof and high sealing performance of Rapid Spiral Doors can effectively isolate the external pollution and keep the internal environment clean and safe.

Automobile Industry

Workshops and paint booths in the automotive industry have strict control over temperature and air quality. The quick opening and closing and high sealing performance of the Turbo Rigid Rapid Door. It can provide good isolation effect and ensure the stability of the production environment.

Installation and Maintenance of Turbo Rapid Spiral Doors

Brief description of the installation procedure

The installation process of Turbo Rigid Rapid Door includes track installation, motor connection, door panel assembly and system commissioning. The professional installation team can complete the whole installation process in a short time to ensure the normal operation of the door.

Recommendations for routine maintenance

In order to ensure the long-term stable operation of the turbo rigid speed door, regular maintenance is essential. It is recommended to carry out a comprehensive inspection once a month to clean the tracks and sensors. Check the operation status of the motor and control system, and deal with any problems found in time.

Frequently Asked Questions and Solutions

There are some common problems that may be encountered during the use of turbo rigid speed doors. Such as poor door operation, sensor malfunction and so on. Through routine maintenance and timely repair, these problems can be effectively solved to ensure the normal use of the door.

Choosing the Right Fast Spiral Doors Supplier

Supplier selection criteria

Choosing a quality supplier of turbo rigid speed door requires consideration of several factors, including product quality, after-sales service, technical support and price. It is recommended to choose a brand with rich experience and good reputation to ensure the stability and reliability of the product.

Quality Supplier Recommendations

1.SEPPES as a leading industrial door supplier in the industry. Their products have a number of product core technology and through the European Union CE, international SGS and ISO9001 quality management system certification. Their partners include many internationally recognized Fortune 500 companies such as IKEA, Tyson, Logitech, Thermo Fisher and many others.

2.Kenvo is one of the earliest professional manufacturers of industrial doors in China market. Since the very beginning, they have been focused on offering complete and customized solution of entrance door system for industrial clients.

3. Master Well specialize in specific products, doors and windows, door related accessories, and kinds of door openers. MASTER’s goal is not to be a general door and window provider. Instead, MASTER seeks to establish ourselves as a high quality provider in the Door & Window market. Master Well Enterprise Limited insists on the principle of sincerity and aims at “prestige first, cooperate sincerely and develop commonly”.

Frequently Asked Questions (FAQs)

1.How long does a High Speed Spiral Door last?

The service life of a Turbo hard fast Door is usually more than 10 years, depending on the frequency of use and maintenance. Regular maintenance and servicing can significantly extend their service life.

2.Are Spiral Doors suitable for all industrial environments?

High speed spiral doors are suitable for most industrial environments. But in extreme high or low temperatures or corrosive environments, specific models and materials need to be selected to ensure proper operation.

3.How to deal with a faulty Spiral Door?

When the turbo rigid speed door is malfunctioning. Professional technicians should be contacted in time for inspection and repair. Daily maintenance and timely handling of small problems can effectively avoid serious failures.