As the global coffee market continues to expand, coffee factories are facing increasingly severe production pressures. In such an environment, improving production efficiency has become one of the top priorities for coffee factory managers. At the same time, in order to protect the safety of workers on the production line. It is particularly important to strengthen the safety measures in the workplace. As a new type of access control equipment, the high speed rolling door has many advantages. For example fast opening speed, energy saving and environmental protection, safety and reliability, so its application in the coffee factory is of great significance.

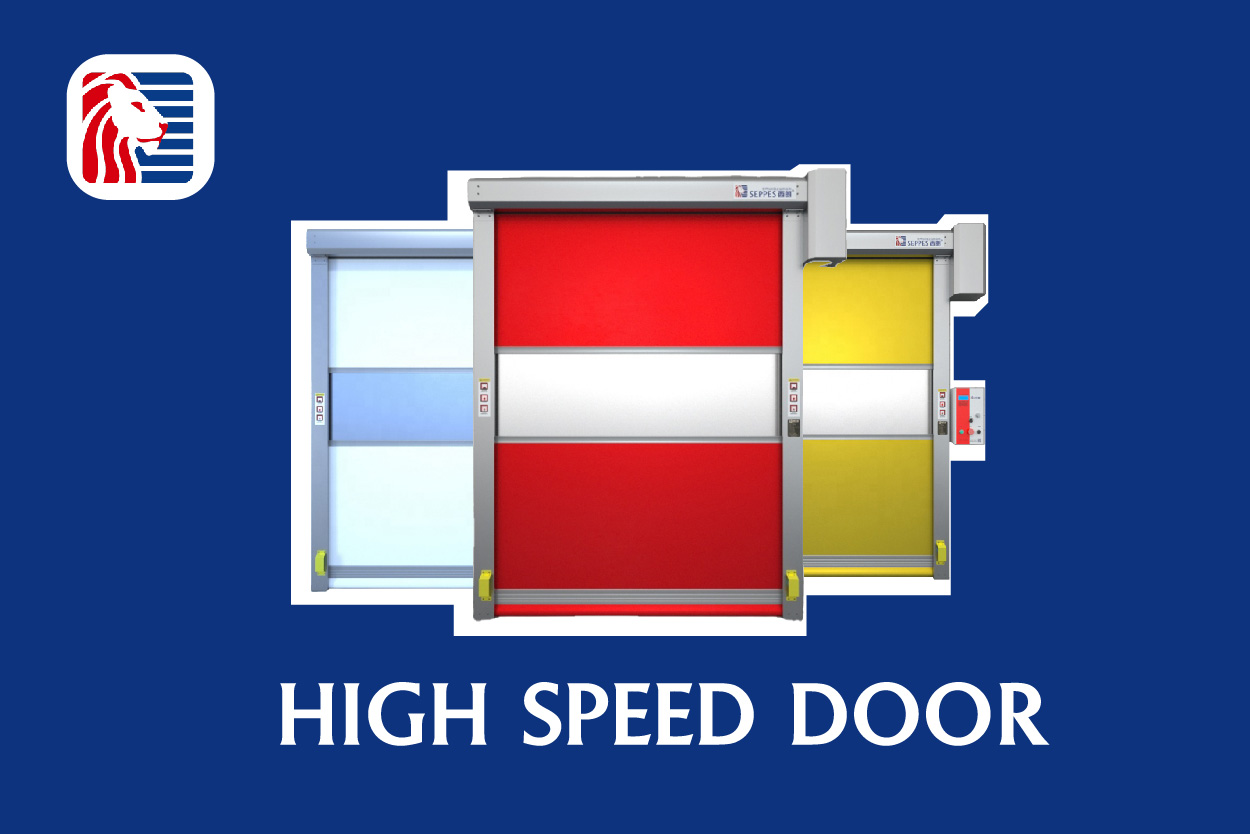

Advantages of the high speed rolling door

High speed rolling doors have several significant advantages:

High-speed opening: fast rolling door can reach 1.5-2.0 M/S opening and closing speed, greatly improving the efficiency of the material in and out, saving production time.

Energy saving and environmental protection: compared with the traditional door. The curtain of the fast rolling door is made of PVC fabric, thickness can reach 2.0 MM. better sealing, can effectively prevent the loss of energy, thus reducing energy consumption, in line with the concept of green production.

Safe and reliable: the high speed rolling door adopts advanced sensor technology. That can detect pedestrians or vehicles in time to avoid accidental collision and protect the safety of the workplace. There are radar, geomagnetic, blue tooth and other ways to open the door, a variety of protection of your safety.

Strong durability: the rapid rolling door is made of high quality material. That has a long service life and reduces the maintenance cost and replacement frequency. The door header box is not easy to be deformed by the roll-folding process. And the overall frame of the door is 304 stainless steel or aluminum alloy, which is sturdy and reliable.

Application examples in coffee factories

A coffee factory purchased a batch of high speed rolling doors in SPEES Doors, which is widely used in the production line. At the raw material import and export. The high-speed opening speed of the rapid rolling shutter door greatly improves the efficiency of the raw material in and out. Reduces the waiting time, and improves the operation efficiency of the production line. At the same time, the installation of rapid rolling doors in personnel-intensive areas effectively prevents accidental contact between workers and equipment, and improves the safety of the workplace.

Factory installation of high speed rolling shutter door implementation guidance

In order to better implement the rapid shutter door technology, coffee factory managers can take the following measures:

Technical selection: according to the actual situation and needs of the factory, choose the appropriate model and specifications of the rapid rolling door.

Installation location: Reasonably determine the installation location of the rapid shutter door to ensure that it maximizes the benefits.

Training of workers: Provide relevant training to workers so that they can operate the rapid rolling shutter door correctly and safely.

Regular maintenance: regular inspection and maintenance of the rapid rolling shutter door to ensure its normal operation.

As a modern access control device, the application of high speed shutter doors in coffee factories is of great significance. By improving productivity and workplace safety, the rapid shutter door creates more value for coffee factory managers. Therefore, coffee factory managers should actively adopt the rapid shutter door technology, and make the corresponding implementation and management measures in combination with the actual situation, in order to promote the sustainable development of the factory.