The rapid development of the global economy has accelerated the pace of the application of industrial doors in factories and logistics and other enterprises. With the popularization and application of industrial doors. Enterprises on the safety, convenience or other special requirements of industrial doors is also more and more high. Today let’s talk about the current classification of industrial door and how we choose.

Application status of industrial doors

For many years, industrial fast doors have been popular in Europe, America and Japan, as well as other developed industrial nations. Especially production-oriented enterprises, workshops and workshops must have rapid rolling door. The government even mandatory provisions of food, pharmaceutical companies must install high speed doors for isolation. To prevent products from secondary pollution.

Throughout China’s rapid door industry, a late start but rapid development, most modern industrial enterprises have begun to focus on the construction of industrial doors. And realize that the installation of fast doors to help improve the efficiency of enterprise production and transportation, especially for insulation sealing requirements of high food, medicine, cold chain and other industries, fast doors are currently the more ideal choice.

Industrial door classification

Industrial doors are mainly categorized as follows: industrial roll up doors, industrial sliding doors, industrial sectional doors, blast-resistant door,insulated door and so on.

Roll up door

Industrial roll up door is made of the door frame, door curtain, drive motor, control system. Material has aluminum alloy, PVC, steel and so on, all belong to the automation control equipment. The performance characteristics of industrial roll up doors made of different materials are different.

PVC high speed door

The rolling door made of PVC soft curtain is usually called high speed door or fast door. With heat preservation, insect-proof, windproof, dustproof, sound insulation, odor prevention, lighting and other functions. Widely used in food, chemical, textile, electronics, printing, storage, precision machinery and other indoor occasions.

Wind-resistant rolling door

It is composed of curtain sheet, wind-resistant wheel, wind-resistant track, opening drive mechanism and other components. The inner layer of the curtain is polyurethane foam, which has the advantages of heat preservation, heat insulation, sound insulation and beautiful appearance.

Spiral Door

Spiral door usually adopts high quality aluminum alloy type material. The center is full of impact-resistant high-strength polyurethane foam, which has excellent impact resistance. At the same time, it has anti-prying function, which effectively prevents malicious intrusion and theft, and protects the safety of goods in the warehouse. The opening and closing speed of the rigid speed door is very fast. It can open and close quickly, thus improving the efficiency and safety of access control in the warehouse. Because of the material advantage, the frequency of maintenance and replacement is reduced.

Industrial sectional door

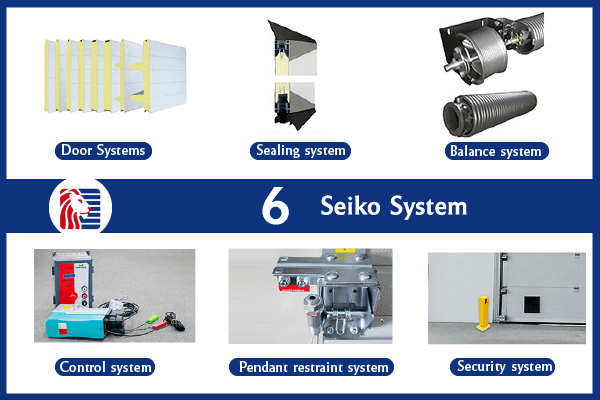

It consists of door body, balancing system, driving and control system, safety device, track and sealing and other optional components. It has the advantages of good heat preservation and sealing, strong mechanical resistance and so on. Widely used due to lower installation conditions and higher practicality.

The lifting methods of industrial sectional doors are divided into three types: standard lifting, sectional vertical lifting and high lifting. The standard lifting industrial door is also called industrial sliding door. And sectional vertical lifting and high lifting two lifting methods of industrial doors are called industrial sectional door.

Industrial sliding door

it is a single or multiple door body, along the designated track phase door opening side or both sides of the movement, to achieve the opening and closing of a door type, its running track for the straight line displacement, also known as the sliding door. It is one of the most popular industrial doors for steel structure plants.

Industrial sliding door can open according to the different ways are divided into: one-way sliding door, two-way sliding door, but also according to the different ways of load-bearing are divided into: on the load-bearing (under the guidance of) sliding door, under the load-bearing (on the guidance of) sliding door, will also be divided into because of the different ways of transmission: rack and pinion drive, ground wheel chain drive sliding door, there are also different ways of driving are divided into: manual sliding door and electric sliding door. Door frame: steel, aluminum alloy, stainless steel three.

Blast-resistant door

Explosion-proof door for the resistance of industrial buildings outside the device accidental explosion. Safeguard the lives of personnel and industrial buildings and the integrity of the internal equipment, from the harm of the explosion shock wave. Effectively prevent the continuation of the explosion hazard. The use of special industrial steel plate in accordance with the strict set of mechanical data production. And with high-performance hardware accessories, more practical and beautiful to use. Can also ensure the safety of life and property. Blast-resistant door is also known as: anti-explosion door.

Insulated door

This kind of professional door is suitable for non-normal temperature state. Such as low-temperature cold storage door, high-temperature area with the door and so on. This kind of door pays more attention to the heat preservation and airtightness, with the pan type as much.

The following use of the most common three kinds of industrial doors: industrial roll up door, high speed door and industrial sectional door to introduce its characteristics.

Characteristics of industrial rolling doors

Industrial rolling door is composed of door frame, door curtain, driving motor and control system. The material has aluminum alloy, PVC, steel and other kinds of material, all belong to the automatic control equipment.

Industrial roller shutters are not only robust and reliable, but also have excellent durability. During start-up, it is very fast and noiseless. It is motorized and can be manually operated in the event of a power failure. It is accompanied by beautiful, safe and transparent profiles with good lighting. Excellent operating performance, long service life and colorful appearance, so that more and more manufacturers choose industrial rolling doors for factories.

The industrial rolling door is driven by the guide rail on both sides. Compared with other lifting doors, it greatly saves the internal space of the building, is more convenient to install, and is easy and reliable to use.

Curtain sheet material: double-layer high-strength, high toughness, corrosion-resistant aluminum alloy extrusion molding.

Surface treatment: classic powder coating process, which is characterized by strong durability, anti-aging, corrosion resistance, no fading, easy to maintain, long as new.

Scope of application: Suitable for external doors of medium and high-grade plants.

Opening speed: average speed up to 12-18 meters per minute

Principle of operation: Multi-jointed movable door pieces are connected together in series, fixed in the guide rail slide, and rotated up and down with the scroll above the door as the center.

Driving principle: Use special motor to drive the center shaft of the rolling shutter to rotate, to reach the rolling shutter switch, and stop automatically when rotating to the upper and lower limits set by the motor.

Characteristics of industrial sectional doors

Industrial sectional door consists of a series of door panels (commonly metal or cloth materials, etc.), along the track up. Industrial lifting door in the appearance of the structural design of the grand, the use of a sense of comfort; and the larger size of the industrial products of its stable, spectacular running posture can bring people a strong visual impact. Torsion spring system or counterweight system to ensure the balance of the door body. The different track systems and lifting methods of industrial lifting door panels make them adaptable to different buildings. Various colors are available. Its dexterity makes it suitable for almost every kind of exterior door.

Types of Industrial Sectional Door

According to the different modes of operation, the industrial door is divided into standard lifting industrial door, vertical lifting industrial door, high lifting industrial door, sliding industrial door, sectional lifting industrial door, special lifting industrial door, European-style industrial rolling door and so on.

Industrial sliding door also known as automatic sliding door, electric sliding door, industrial sliding door body thickness of 40-50mm, industrial lifting door can be suitable for every kind of building outside the door.

Applicable industries and scenes

pharmaceutical, food, electronics, printing, supermarkets and other cleanliness requirements of the plant and regional isolation. It is characterized by beautiful appearance, high strength, safety and reliability, smooth opening, low noise, good sealing and heat preservation performance, saving space and improving production efficiency. It is widely used due to lower installation conditions and higher practicality.

Lifting Methods

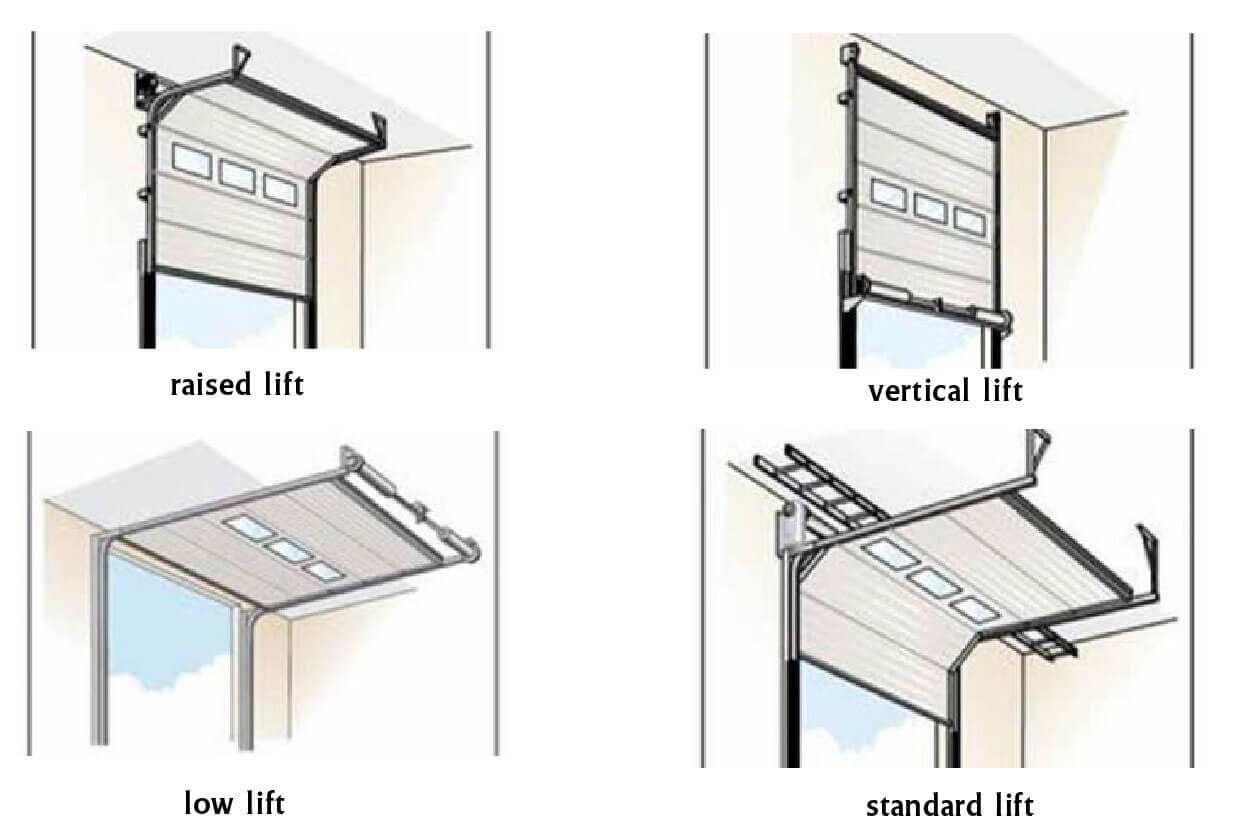

There are various ways of lifting an industrial liftgate, depending on the space available at the installation site.

1.Standard lifting: It usually applied to the space above the doorway of about 500mm or so, is a more common lifting method.

2.Improve lifting: It is suitable for places with more than 500mm space above the door opening.

3.Vertical lifting:It is suitable for places where the space above the door head is greater than or equal to the height of the door opening, which needs to have enough height.

4.Low turn lifting: It is suitable for complex places where the space above the door head is less than 500mm or where there are obstructing pipes or beams.

5.Inclined position turn lifting:It is suitable for places where the roof has a slope, the door plate can run along the wall with a slope after rising, with strong applicability.

Characteristics of High Speed Door

High-speed opening and closing:

Rapid rolling door adopts motor drive and high speed rolling system. Rapid opening and closing can be realized, which improves the efficiency of passage at entrances and exits. In contrast, ordinary industrial doors take longer to fully open or close, which may affect production and logistics efficiency.

Space saving:

Rapid rolling doors are usually more compact in design and do not require additional opening space, making them suitable for installation in locations where space is lacking. In contrast, some common industrial doors, such as sliding or swing doors, require sufficient opening space. This limits their use in certain environments.

Superior sealing:

Quick roll-up doors utilize high-quality sealing materials and designs that effectively isolate the indoor and outdoor environments. This superior sealing reduces energy consumption, maintains constant indoor temperature and humidity, and reduces the load on air conditioning and heating systems. In contrast, ordinary industrial doors may have poor sealing performance, leading to energy waste and poor environmental control.

High security:

Rapid rolling doors are usually equipped with a variety of safety protection devices. For example, infrared sensors and crash bars can detect pedestrians or vehicles in time to avoid accidental injuries. This high level of security is especially important for places that are frequently accessed in industrial environments. In contrast, although ordinary industrial doors can als equip with safety devices, they may not be as well-designed as rapid rolling doors.

Selection elements for industrial doors

1.The principle of practicality

the so-called practicality, means that the door should be able to meet the actual needs. These doors have a variety of models, specifications, functions, and the applicability of each type of door and price are different. Configuration from a practical point of view, is to consider both to meet the performance and save investment. A good solution, first of all, must be the most suitable for their own business needs and use.

2.The principle of wholeness

wholeness is in the door configuration to systematically consider the entire process. In the door of the model, number, control and other aspects of a reasonable setup, in order not to leave any bottlenecks. Door is not just a simple switch of the ancillary facilities. Its speed, airtightness, service life, safety, reliability, ease of maintenance, operating costs, noise impact, etc. are factors to be considered.

3.The principle of security

security refers to the setup of safety devices according to the site conditions. Safety is gradually accepted and recognized by more and more customers, especially with the process of goods circulation running more and more frequently. The turnover rate of goods increased, loading and unloading of goods, the amount and frequency of goods in and out of the increasing. All kinds of security risks also arise. So not only to consider the basic use of the door function, but also to consider the door safety devices.

4. The door of a very large number of types, how to choose the form of the door?

Which is very necessary to understand the project planning program to determine the nature of the project. The nature of the project determines the program of the process, such as to determine the project is a production plant or logistics center; is a food project or pharmaceutical project or other projects and so on. Understanding these circumstances is crucial to understanding the production and storage environment requirements. Because these factors are directly determined by the form of the door, size, opening and closing speed, frequency of use, airtight performance, thermal insulation performance.

5. Understanding the production and logistics process

Master the interrelationship between the regions, configure the appropriate equipment. Such as: how to use the door process? The type of vehicles passing through? Is there a need for the passage of personnel? How to ensure safety?

6. The door of the choice of control mode

is to determine the efficiency of a passageway operation is an important factor. We have to consider in this passage. Need to control how to open and close the door, at the same time to ensure that the channel is smooth and efficient, but also to ensure that the operation of the safety and convenience. And sometimes also need to consider the communication and linkage function between the doors or and the central control center. So the selection of the appropriate control method is to allow the door to play its maximum function of one of the important factors. A good door only configured to meet the logistics process requirements of the control system in order to maximize its role.

7.Determining the door varieties, models, quantities, specifications

In fact, this is often overlooked a problem. The form of the door can be different, the number of doors should be designed in conjunction with the characteristics of the process, and a certain degree of foresight. Doors are also controlled in different ways, so set in stone, or a thousand changes may be counterproductive. Must be based on the characteristics of the company to make targeted choices, it is possible to make the best program to.

Comparative advantages

Rolling Door Advantages

The material of the rolling door is more diversified, and each material has its advantages. The advantages of the choice of motor type are diversified. The switching methods mainly include manual switch, electric switch, bluetooth switch, remote control switch and so on. The characteristics of the roller shutter door differ according to the type, the roller shutter door as a whole has more options, more cost-effective, more cost-effective.

Sectional Door Advantages

1.Strong applicability

Industrial doors can be customized according to the architectural features of industrial plants. The industrial plant with enough space above, its lifting door opens vertically upward, hangs flat on the inside of the wall above the doorway, does not take up any space in the room, and gives full play to the vertical rise. It does not occupy the advantages of both sides of the doorway, and releases the space of the doorway to a large extent.

2.Convenient and beautiful

Industrial sliding doors use torsion spring balance system to balance the weight of the door. It makes the gate easy to run without a motor, changing the mode of rolling doors that only rely on the motor to run. It increases the convenience of using the gate.

The material of the industrial door is double-layer galvanized steel plate filled with polyurethane foam. The thickness of the whole door body reaches 40mm, and the surface adopts embossed design. It can make the door plate durable, easy to clean, beautiful and generous, and can enhance the corporate image.

3.Thermal insulation

The double-layer steel plate of the industrial door reduces the consumption of heat energy. The 42kg/m3 high-density polyurethane thermal insulation layer is sandwiched inside, which has a good thermal insulation effect.

4.Noise isolation

The industrial liftgate operates with extremely low noise. Galvanized pulley blocks equip with adjustable ball bearings and wear-resistant rubber wheels. Ensure the door can openSafety protection devices: and close silently. Overcome the shortcomings of the roller shutter door running noise, and make the door running more smoothly.

High Speed Door Advantages

1.high speed opening and closing

Rapid rolling door has fast and smooth opening and closing action. Its speed can reach 1.2-2.0m/s. It can respond quickly to opening commands and improve the efficiency of passage. Its design and manufacturing process can ensure that the door body can run at high speed. It does not affect the stability and safety of the door.

2.Safety protection devices

These doors are usually equip with a variety of safety protection devices. Such as infrared sensors, anti-collision strips, etc., which can detect pedestrians or vehicles in time to avoid accidental collision or pinching accidents. Excellent rapid rolling doors excel in security. It can effectively protect the safety of personnel and equipment.

3.Excellent sealing performance

The fast rolling door is made of high quality sealing material and design (EPDM rubber strips). It has excellent sealing performance. This sealing performance can effectively isolate the indoor and outdoor environment. Maintain a constant temperature and humidity in the room, reduce energy consumption, improve productivity.

Trends in industrial door technology

1. more specialized design: the standardization of industrial production requires industrial doors with more professional design team and technical staff.

2. integrated better integration: networked logistics management facilities. Industrial door control will become an important core factor in logistics management. Therefore, the combination of management software and operational control will be inevitable.

3.a higher degree of equipment: in the past, industrial warehouses around the industrial door simply can not meet the functional needs of human beings. There is no industrial doors and logistics facilities in the same perspective to consider. Modern industrial door design is basically in line with the actual production needs, and take into account the function to maintain how long.

4. more intelligent design: industrial door industry in order to meet the existing and hidden market demand. Continuous improvement, continuous intelligent products is inevitable. The more intelligent products can make the enterprise to get more market opportunities and earn more business profits. Therefore, industrial door manufacturers should pay more attention to the design of product intelligence.