Sectional door is a modern factory use door. It is an industrial door with good heat preservation, wind resistance, sound insulation and good sealing. With manual and electric switching mode, it is easy to operate and fast to open. And the installation track is on both sides of the door opening, which does not take up extra space. In many door categories, industrial liftgate has become the first choice of factory door because of its unique advantages. Next, I will synthesize a number of aspects to introduce you to industrial sectional doors.

The Importance of Industrial Sectional Door

Industrial sectional doors play an integral role in modern manufacturing. Not only are they used to protect work areas from external environmental disturbances and damage, they also help to control internal temperature, humidity and air quality. In addition, liftgates can help manage the flow of people and equipment, ensuring safety and efficiency. Industrial door is characterized by high reliability. It is made of high-strength steel or aluminum alloy materials. With strong wind and impact resistance, it can effectively protect the equipment and goods inside the plant from the external environment. At the same time, the lifting door is also equipped with safety sensing device and emergency stop device. It is able to detect abnormal conditions and stop operation in time to ensure the safety of the workplace.

Secondly, the industrial door is characterized by easy operation. It adopts an electric drive system. It can be operated remotely by remote control, button or intelligent control system without excessive manual intervention. The industrial liftgate is also characterized by fast switching speed, low noise and smooth operation. The opening and closing of the liftgate is not only fast and convenient, but also can effectively avoid the interference of noise on the working environment.

What makes sectional doors the first choice for many factories?

Good safety

Industrial doors are usually equipped with safety devices. Such as infrared sensors, collision avoidance devices, airbags, etc., which can effectively prevent personnel or vehicle collision. The safety device will enable the industrial liftgate to open upwards in reverse after a quick reaction. Each SEPPES sectional door spring is equipped with a spring breakage prevention device. In case of any spring breakage, the industrial door stops immediately within 20cm.

Good durability

Industrial doors usually use double layer is color steel plate, aluminum alloy or 304 stainless steel as the door plate material. And the surface is embossed, with orange peel pattern and imitation wood grain optional. Sturdy and durable at the same time also beautiful and generous, greatly increasing the aesthetics of the enterprise. In order to ensure that the door body is strong and does not add weight to the door body. Usually for the two door panels are filled with high-density polyurethane foam. This can be very good impact resistance, but also reduces the weight of the whole door plate. In addition, the industrial lifting door also has a long service life. The service life is mostly 10-15 years, which reduces the maintenance cost.

Good energy efficiency

Industrial doors usually use environmentally friendly insulation materials and sealing technology. It can effectively insulate the temperature difference between indoor and outdoor and reduce the transfer and dissipation of energy. This energy-saving design not only helps to reduce the energy cost of the factory. It also helps to improve the environmental quality of the factory and create a more comfortable working environment for employees.

Good Convenience

Industrial sectional doors also have a variety of opening methods. Such as manual, electric, remote control, radar, far red photoelectricity, etc., can meet the needs of different factories.

Support Personalization

Sectional doors are flexible in design. They can be customized according to the actual needs of the factory’s on-site building. Whether it is size, color, material or function, industrial doors can meet the individual needs of factories. This diversity makes industrial doors have wide applicability in the factory door market. Meet different industrial environments and use scenarios.

Environmental adaptability and multiple lifting methods

There are various lifting methods for industrial lifting doors. It depends mainly on the space available at the installation site.

Standard Lifting:Usually suitable for places where the space above the doorway is around 500mm or so, this is the more common type of lift.

Raised lifting: Suitable for places where the space above the doorway is greater than 500mm.

Vertical lifting: Suitable for places where the space above the door opening is greater than or equal to the height of the door opening, and needs to have enough height.

Low turn lifting: Suitable for places where the space above the door opening is less than 500mm or where there are complicated places with obstructing pipes or beams.

Inclined turn lifting: Suitable for places with sloping roofs, where the door panel can run along the sloping wall after rising. It has strong applicability.

Difference between sectional door and industrial roll up door

Door Body Differences

The sectional door is mainly made of pressed aluminum plate, and the door plate is surrounded by an aluminum alloy frame. When the whole door body is too large, it will be fixed with reinforcement. Therefore, the bearing capacity of the door body will be greatly enhanced, and there will be no uneven force.

Roller shutter door is a multi-jointed door piece in series. Doors that rotate up and down with the rolled curtain above the door as the center. It consists of 13 parts such as curtain panel, guide rail, support, rollers, door rollers, manual speed release closing device, push button switch and safety device.

Track Differences

The track of the sectional door is mainly composed of guide rail, sub rail, fixing parts, etc. It is mainly 2.0mm thick galvanized steel plate. The track of the lifting door is mainly 2.0mm thick galvanized steel plate. Between the track and the sub-track is bolted for easy dismantling and after-sale maintenance. And there are sealing strips embedded in the track, the sealing between the tracks is good, high strength. The sealing strip can effectively prevent dust and other foreign objects from entering. Reduce the track due to dust, stones and other small objects caused by the use of failure. At the same time, the secondary rail has a hand guard design to reduce the occurrence of accidents.

Roller doors use aluminum or steel profiles for their tracks. Generally there may be a situation where the rolling door is off the chain. Industrial door manufacturers do not add brushes or seals inside the track if they do not add brushes or seals. There will be a large noise when running.

Balancing System Differences

Sectional doors use torsion springs and a center beam to balance the weight of the door during operation. Reduces dependence on the motor during operation. This aspect of the door regulates its own balance during operation and operates with low noise.

Roller shutter doors are mainly doors that rotate with the upper shutter as the center. It relies mainly on the weight of the door itself to maintain balance.

Material Differences

Sectional door body is generally composed of double-layer galvanized steel plate filled with polyurethane foam inside. Or color steel plate filled with polyurethane composition.

Rolling shutter door body generally have color steel plate, stainless steel, aluminum alloy and PVC and other materials. Subdivided into categories roughly divided into high speed door and spiral door.

Structural Differences

Sectional doors have a horizontally split folding connection in the body of the gate. It makes the door easier to repair and replace. Small doors and windows can also be opened.

Rolling up door is a multi-jointed movable door piece in series. Inside a fixed chute. Rotating up and down with the rollers above the door as the center, no small doors or windows.

Differences in places of use

Sectional doors are generally used in factories, airports, etc.

Roller shutter doors are generally used in commercial storefronts, garages, shopping malls and residences.

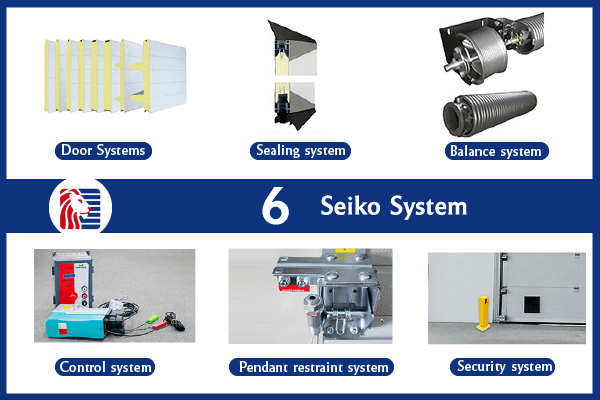

What are the components of common parts of industrial sectional door?

An industrial liftgate is made up of a combination of various components such as door panels, motors, balancing systems, safety devices, hardware and accessories. The material composition requirements of different parts are also different. So, what are the materials that make up the common components of industrial sliding doors?

Door panel

Door panel is one of the main components of industrial liftgate. Generally speaking, the thickness of the industrial lifting door plate is 40mm, the door plate material is made of double color steel plate filled with polyurethane foam material combination. For some oversized industrial doors. Need to be set in the inner side of these door panels have T-shaped reinforcement. In order to ensure the strength of the door plate, enhance wind resistance.

Balance system

Industrial sectional doors are large and heavy. In order to facilitate the daily lifting and closing, industrial doors are set up with torsion spring balance system. According to the comprehensive design and production of torsion springs. Make industrial lifting door in the process of rising, falling always keep the balance state, convenient industrial door opening and closing. Most of the torsion springs of industrial doors are made of imported spring steel. Can make its service life can be more than 80000 cycles.

Transmission system

It consists of industrial door motor, transmission shaft, balancing system, wire rope, wire rope sheave and other parts.

Door system

It consists of door panels, auxiliary rails, straight rails, curved rails, small windows, small doors, hardware accessories and other parts.

Operating system

It consists of control box, remote control and other parts.

Security system

1. Wire rope fall prevention device: mainly located at the bottom ends of the door, to solve the lifting wire rope breakage caused by the door falling. The device can make the falling door plate instantly cut in under the action of spring force to stop falling. Effectively avoid the safety of the people below the door.

2.Safety photoelectric protection device: mainly located on both sides of the door, usually a pair. When a person triggered to the infrared photoelectricity, the door to keep immobile. Ensure the safe passage of people and vehicles. Be careful not to place objects for a long time in the safety photoelectric sensing range.

3.Airbag protection device: mainly located at the bottom, connected with the motor. Able to sense the door in the process of descending to touch the person or object, after touching the automatic rise. The principle is that the air inside the internal airbag is squeezed by the outside. Send the information to the control box, through the control box system makes the motor reverse rotation. Safeguard the use of safety.

4. Torsion spring anti-break device: mainly located in the door shaft, if the torsion spring breakage occurs. The snap parts of this device will be stuck in the track within the pulley, can effectively prevent the door axis rotation. So that the door plate stuck in 10cm will not continue to fall.

5. End buffer: usually located at the top of the track. Prevents the motor from malfunctioning and causing the door panel to rise out of the track. Play the role of buffer when up and boost when down.

Application Scenarios for Industrial sectional doors

1.Industrial sectional door is widely used in industrial production field. In all kinds of factories, warehouses and logistics centers and other places. Industrial lifting door by virtue of its unique design and excellent performance for the production also provides convenience. Vertical lifting, horizontal opening mode. Industrial lifting door not only saves space, but also improves operational efficiency. Its excellent heat preservation, sound insulation, anti-theft, windproof and other functions provide strong support for industrial production.

2.In the commercial field, such as large shopping malls, supermarkets, parking lots and other places. Industrial lifting door with its atmospheric, beautiful appearance for commercial facilities to add color. The advantages of its fast opening and passage efficiency for the commercial premises of the flow of people, logistics to provide convenient services. The lifting door can also provide strong anti-theft effect for these places.

3.Public facilities field, such as hospitals, schools, stadiums and other places. The convenient and safe performance of industrial lifting door provides convenience for the management of public facilities. At the same time its good sound insulation and heat preservation performance for public facilities to provide a comfortable environment.

There are four key factors to keep in mind when selecting a high-quality sectional door

1.Choosing the right material

For sectional overhead garage doors, the choice of material plays a crucial role. You have options such as aluminum and stainless steel. Aluminum overhead doors are preferred for their lightweight, corrosion resistance and strength. Making it suitable for both commercial and residential structures. On the other hand, stainless steel sectional door offers unmatched durability and safety. Making them ideal for harsh environments such as chemical plants.

2.Fulfillment of functional requirements

It is critical to customize sectional doors to meet your specific functional needs. Depending on the needs of your business. You can equip the door with features such as explosion-proof features or one-touch linkage systems. For example, in environments where there is a risk of dust or explosions, choosing explosion-proof features is imperative. Similarly, if your door will be used by the fire department. A one-touch linkage feature may be a life-saving option. When a fire alarm sounds, all fire elevator doors will automatically open upon receiving the emergency signal. This improves response time and efficiency.

3.Harmonization of design styles

The design style of your liftgate should blend seamlessly with your architectural aesthetic and surroundings. You have a variety of design options to choose from. These include custom colors, sizes and lifting methods. Choosing a design style that complements the overall appearance of the building and your personal preferences can enhance aesthetics and visual impact. In addition, consider the four available lifting methods to maximize space efficiency. Also consider the unique environment of your site.

4.Trusted and reliable brands

It is vital to research the reputation and product quality of your industrial door manufacturer. Choose a supplier with a proven track record and extensive experience in the industry. In addition, evaluate warranties and after-sales support to ensure you receive prompt maintenance and assistance after purchase. Consider brands like Horman, Seppes or Crawford, known for providing excellent after-sales service and strong warranty policies. This ensures timely resolution of issues and supports the proper functioning and longevity of the door. Their products excel in noise reduction, efficiency and security, making them a reliable choice for your needs.

What are the considerations for installing an sectional door?

1, before installing the door, note that the size should be the same as the pre-designed size of the sliding door. Accurate calculation of the doorway as well as the space position on both sides. Meet the installation conditions can continue to install the sliding door.

2, pay attention to the problem of lifting door sliding, installation of both sides of the track plane must be consistent. If the slide is not deep enough, the structure and materials used are not good. When a fire accident occurs, the door curtain is easy to slip and slide, and can not play a role in fire protection.

3, pay attention to the pre-roll problem of the door, industrial lifting of the door is heavier. In order to reduce the net weight of the curtain of industrial lifting on the tensile strength of the screws. Prevent the split industrial sectional door drive system and the compressive strength of the curtain shaft.

4, pay attention to the safety and protection of the sliding door. The door must be configured with the corresponding safety protection airbag device. Installation can be in the event of an emergency failure to rebound state. Lift the door must be configured to prevent spring breakage and anti-wire spring breakage protection device. So as to play a role in the protection of personnel and objects. Also need to install the overload failure protection motor device in the door above.

What is the maintenance of a sectional door?

You can use a wet towel to wipe the door panel. If the stain is too heavy, you can’t use a hard object to scrape it off. It will damage the door panel and leave scratches. You can wipe it with the use of a special cleaner. Then wipe with water and wipe dry.

You should clean the debris in the guide rail of the liftgate in time, and you need to add lubricant regularly to ensure that the guide rail and the roller can operate effectively.

The torsion spring on the liftgate will cause it to loosen with everyday use, you just need to tighten it periodically.

The motor of the sectional door drives the whole door panel to run. If there is a strange noise you need to check whether there is a malfunction inside. If you are not sure of the cause of the malfunction you need to call the industrial door manufacturer for repair.

Check whether the wire rope and spring are broken and cracked on time, and replace the stainless steel wire and spring in time.

FAQ

Q: What material is the sectional door ?

A: Door frame 2.0mm galvanized steel. Door body material 0.4mm color coated steel plate, filled with polyurethane industrial foam insulation material, density of 48 ± 2KG/m³. Thermal insulation performance is better .

Q: What safety devices are available for industrial sectional doors?

A:1.Wire rope fall prevention device 2.Safety photoelectric protection device 3.Airbag protection device 4.Torsion spring anti-break device 5.End buffer

Q: What is the usual size of an industrial ? How windproof are they?

A: The standard size is 4*4, windproof grade 11. If it is larger than the standard size, you need to consider doing the reinforced windproof treatment.

Q: How fast does the sectional door operate?

A: 0.2-0.3m/s

Q: Recommended suppliers of industrial doors

A: Horman, Seppes, Crawford, DYNACO, Rite

And how in that case to act?

Contact me and I will solve your problem

It is delightful

Unequivocally, ideal answer