Mechanical dock shelters play a vital role in the logistics and warehousing industry, as they not only improve loading and unloading efficiency, but also protect goods and people from harsh weather conditions. This thesis aims to provide five top tips on how to choose the best mechanical dock shelter equipment. By understanding the needs and environment, considering durability and quality. Focusing on safety, considering maintenance and servicing, and referring to customer reviews and testimonials. Readers will be able to make informed choices that meet the needs of their logistics operations and ensure the long-term reliability of their equipment.

Differences between mechanical dock shelter and sponge and inflatable dock shelter

Mechanical dock shelter, sponge dock shelter and inflatable dock shelter are three common types of mechanical dock sheltering devices. And there are a number of differences between them in terms of their construction, materials and operating principles

Principle of construction

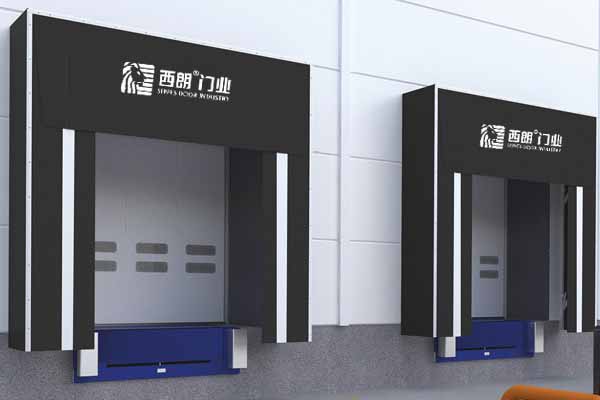

Mechanical dock shelters: Usually consists of a metal frame and a flexible sealing material, usually rubber or other durable elastic material.

Sponge dock shelters: made of a soft sponge material, commonly polyurethane sponge and foam sponge.

Inflatable dock shelters: consists of an air bag and air pump, usually made of durable polychloroprene or polyurethane.

Principle of operation

Mechanical dock shelters: In contact with the transportation vehicle through the door header. It forms a seal that prevents external substances such as gases, dust and insects from entering the cargo handling area.

Sponge dock shelters: Similar to the mechanical dock shelter. The softness of the sponge material is utilized to form a seal in contact with the transport vehicle to prevent the entry of external substances.

Inflatable dock shelters: Inflatable airbags are used to form a seal with the transportation vehicle to prevent external substances such as gas and dust from entering the loading/unloading area.

Applicable environments

Mechanical dock shelters: suitable for most dock environments, simple structure, easy to install.

Sponge dock shelters: soft, flexible, able to adapt to different shapes and sizes of vehicles.

Inflatable dock shelters: very good sealing performance, can adapt to various vehicle shapes and sizes.

Advantages and disadvantages

Mechanical dock shelters: easy to install, wide range of applications, sealing effect and sponge dock shelter.

Sponge dock shelters: soft, better sealing performance, but the durability may not be as good as mechanical dock shelter.

Inflatable dock shelters: excellent sealing performance. Can effectively adapt to a variety of vehicle shapes, but the installation and maintenance costs are higher.

How to Choose the Right Mechanical Dock Shelter

Understanding needs and environment

Before selecting mechanical dock shelter equipment. It is important to have an in-depth understanding of your needs and the environmental conditions in which you are operating. This includes considering factors such as the size of the dock, the expected cargo flow, logistics, and climatic conditions. For example, in harsh climates. Such as cold winters or hot summers, it may be necessary to choose equipment with better insulation properties.

Consider durability and quality

The durability and quality of mechanical dock shelter equipment is a key factor in its long-term performance. It is critical to choose equipment that is made from quality materials, has sturdy construction. And has been fully tested and certified. Durable equipment not only reduces maintenance costs, but also ensures consistently efficient logistics operations.

Focus on safety

Safety is an important factor that should not be overlooked when choosing mechanical dock shelter equipment. The equipment should comply with relevant safety standards and be equipped with the necessary safety features. Such as safety sensors and anti-collision devices, to minimize the likelihood of accidental injury and damage occurring.

Consider maintenance and upkeep

Choosing mechanical dock shelter equipment that is easy to maintain and service can reduce operating costs and extend the life of the equipment. Look for equipment that is simple in design, easy to clean and maintain, and ensure that replacement parts and technical support are available in time for repairs and maintenance when needed.

Refer to customer reviews and testimonials

Checking customer reviews and testimonials can provide valuable references for choosing the best mechanical dock shelter equipment. The experiences and opinions of other users can help you better evaluate the performance and reliability of your equipment and select the make and model that best suits your needs. Internationally known door seal companies Rite-Hite (USA), SEPPES(China), have been recognized by their customers for the quality of their mechanical dock shelters and other loading and unloading equipment.

In summary, by understanding the needs and environment, considering durability and quality, focusing on safety, considering maintenance and upkeep, and referring to customer reviews and testimonials, you can select the best mechanical dock sheltering equipment to meet the needs of your logistics operations and ensure the long-term reliability of your equipment.