In today’s growing global economy, the Philippine region’s factory industry is booming and has become one of the hot markets attracting the world’s attention. As a leader in the factory door industry. Our company is honored to be able to establish a long-term and stable relationship in the Philippines. In this article, we will explore the wide range of applications for factory door in the Philippines and provide insights into why our Filipino customers choose us and the deep trust and long-term trade relationships we have built with factories in the Philippines.

Overview of Philippine Industry

Current Development of Philippine Industry

Transformation of industrial structure: The industrial structure of the Philippines is gradually transforming from traditional agriculture. And light industry to manufacturing and service industries. Manufacturing and services have become the main economic pillars, including electronic products, textiles, food processing, and tourism.

Foreign Investment-Driven: The Philippines relies on a large percentage of foreign direct investment (FDI) for its industrial development. FDI firms have set up factories and production in the Philippines, contributing significantly to the country’s exports and employment.

Uneven regional development: There are regional differences in the industrial development of the Philippines. With the capital city of Manila and its surrounding areas being more concentrated and developed. While some remote areas are lagging behind in industrial development.

Industrial structure and characteristics

Manufacturing Dominance: Manufacturing is the dominant sector of Philippine industry, including electronics, textiles, food processing, chemicals, and other industries. As one of the global centers of electronics manufacturing. The Philippines’ electronics manufacturing industry occupies an important position in the industry.

Dominated by Small and Medium-sized Enterprises (SMEs): Philippine industry is dominated by small and medium-sized enterprises (SMEs). Most of which are small in size and have limited technological and production capacity. These enterprises play an important role in providing employment opportunities and promoting economic growth.

Export-oriented economy: Philippine industry is export-oriented and exports are an important pillar of Philippine industry. Electronic products, textiles, pharmaceuticals and other products are the main export commodities of the Philippines. And the export markets are mainly concentrated in countries and regions such as the United States, Japan and China.

Human Resource Advantage: The Philippines has abundant human resources and relatively low labor cost. Which attracts a large number of foreign-funded enterprises to set up production bases in the Philippines. However, at the same time, there are also problems of skill shortage and poor labor quality.

Basic Concepts and Classification of Factory Doors

Definition and Function of Factory Door

Definition: Factory doors are doors installed in industrial plants, warehouses, commercial buildings and other places. Used for the entrance and exit of people and goods, as well as controlling the environment, ensuring safety and other functions.

Function:

Entrance and Exit Function: Provide access for personnel and goods to facilitate entry and exit from the plant or building.

Security: To protect the security of the plant inside and outside, preventing the entry of unauthorized personnel or goods.

Environmental control: Control temperature, humidity, ventilation and other environmental factors inside and outside the plant to maintain the production environment.

Logistics management: Facilitate loading and unloading, transportation and storage of goods, optimize the efficiency of logistics management.

Different types of factory doors and their characteristics

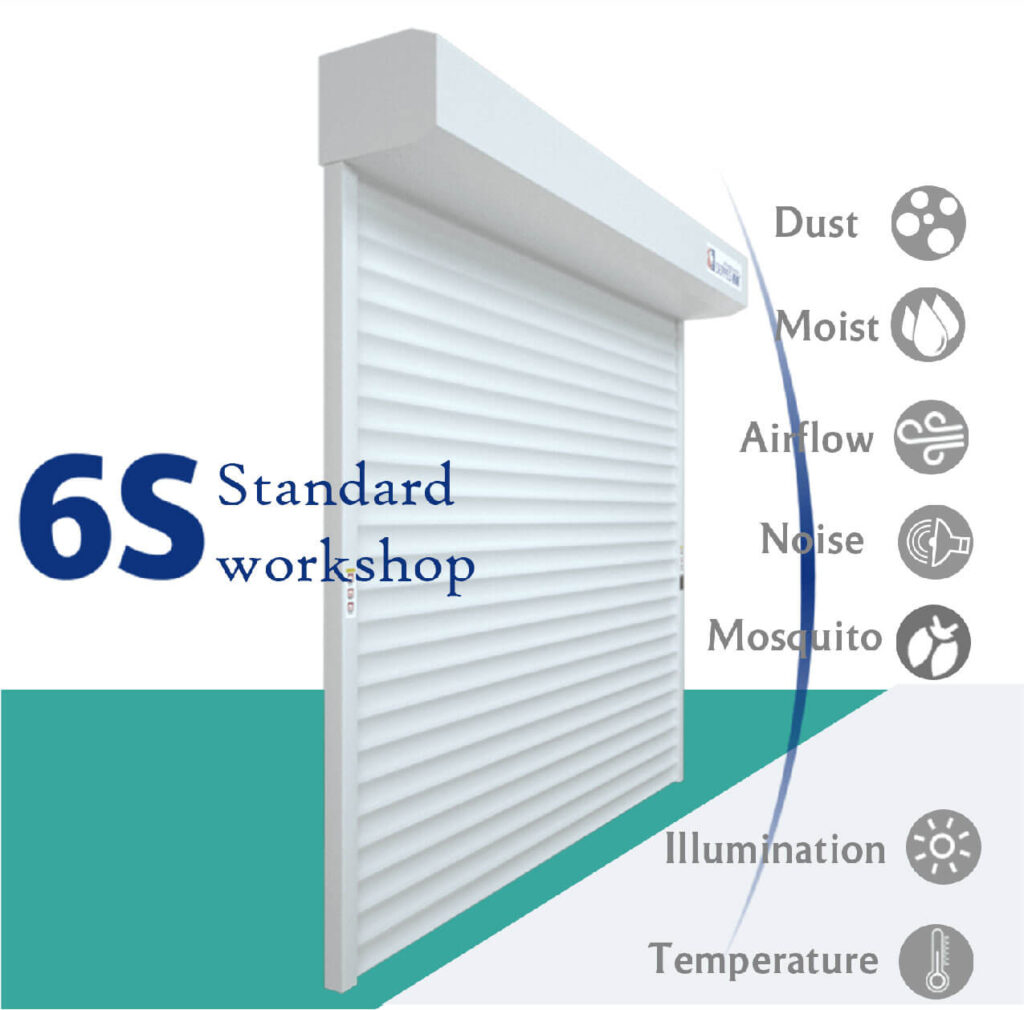

Characteristics: Composed of a series of horizontally stacked metal or aluminum alloy panels, raised and lowered by rollers. Suitable for workshops, warehouses and other places of the door, with fast opening speed, occupying a small space.

Application Scenario: Suitable for the demand for frequent entrances and exits, such as workshops, warehouses and so on.

Characteristics: fast opening and closing speed, can realize the rapid passage, suitable for high-frequency use of the place.

Application Scenario: Suitable for logistics centers, cold storage. Clean rooms and other places with high speed requirements for entrances and exits.

Characteristics: similar to ordinary interior doors, through the hinges in the door frame swing open and close. Suitable for personnel entrances and exits.

Application Scenario: Suitable for offices, laboratories and other places where the frequency of personnel in and out is high.

Characteristics: the door body parallel sliding open and close. Occupying a small space, suitable for places with a large width of the entrance.

Application Scenario: Suitable for warehouses, shopping malls, supermarkets and other places with a large width of the door.

Features: opening and closing speed is very fast, can be quickly restored to the closed state. For frequent access to the high-speed process environment.

Application Scenario: Suitable for food processing plants, pharmaceutical manufacturing plants and other places with strict requirements for the entrance and exit environment.

The Role and Significance of Factory Doors in Philippine Industry

Enhance Industrial Production Efficiency

Provide smooth logistics channel: As an important part of the entrance and exit. Factory door ensures the smooth entry and exit of materials, equipments and personnel. Which helps to improve the production efficiency and process operation.

Optimize the production environment: By controlling the opening and closing of the factory door. It can effectively regulate the temperature, humidity, ventilation and other environmental factors inside and outside the plant. Providing a good working environment for the production operation and improving the production efficiency.

Safeguard the safety environment

Control of import and export security: Factory doors, as part of the security protection facilities, prevent unauthorized personnel or goods from entering by restricting the opening and closing of import and export, so as to guarantee the security inside and outside the factory.

Fire and burglary prevention: Some factory doors are equipped with fire and burglary prevention functions, which can effectively stop fires and thefts from occurring and safeguard factory equipment and personnel.

Promote the process of industrial modernization

Introduction of intelligent technology: With the development of science and technology, more and more factory doors adopt intelligent technology, such as automatic induction, remote control, etc., which improves the intelligent level of industrial production and promotes the process of industrial modernization.

Improvement of industrial environment: Through the use of advanced factory door technology, the industrial production environment can be improved, reduce energy consumption, reduce pollution emissions, and promote the green development of industry and sustainable development.

Potential Impact and Value of Factory Doors in Philippine Industrial Development

Promote industrial upgrading and transformation: Through the introduction of advanced factory door technology and equipment, the production level and competitiveness of Philippine industry can be enhanced, industrial upgrading and transformation can be promoted, and the optimization and upgrading of industrial structure can be realized.

Attracting foreign investment: Industrial parks or enterprises with advanced factory gate facilities and equipment are more attractive and can attract more foreign investment to promote the development and expansion of Philippine industry.

Cultivate emerging industries: The continuous innovation and progress of factory gate technology provides strong support for the development of emerging industries, such as smart manufacturing, Internet of Things and other fields, laying a solid foundation for the future development of Philippine industry.

Analysis of Factory Doors and Factory Partnership in the Philippines

Factory doors play a key role in Philippine factories as an indispensable and important part of the industrial production process. In this section, we will analyze the reasons and considerations for factories in the Philippines to choose factory doors, as well as the modes and methods of cooperation between factory door suppliers and factories in the Philippines.

Reasons and considerations for choosing factory doors in Philippine factories

Quality and Durability: Quality and durability are the primary considerations for Philippine factories when choosing factory doors. A quality factory door can operate stably for a long period of time, reduce maintenance and replacement costs, and increase productivity.

Safety and protection: Due to the changeable climate and frequent natural disasters in the Philippines, factories need to choose factory doors with good fire prevention, anti-theft and other safety and protection features to protect production equipment and employee safety.

Adaptation to environmental conditions: As the Philippines has a diverse geographical environment, factory doors need to be able to adapt to different climatic conditions and environmental requirements, such as wind resistance, waterproof and other features.

Cost-effectiveness: Factories need to consider cost-effectiveness based on product quality and performance, and choose reasonably priced and cost-effective factory doors to reduce investment costs and operating costs.

Modes and modes of cooperation between factory door suppliers and factories in the Philippines

Customized service: Factory door suppliers can provide customized doors and services according to the actual needs and environmental characteristics of factories in the Philippines to meet the individual needs of customers.

Technical support and training: Factory door suppliers can provide technical support and training services to help Philippine factories to select, install and maintain factory doors in a reasonable manner, so as to improve the operational efficiency and service life of the equipment.

After-sales service:Moreover, factory door suppliers must provide timely and professional after-sales service, including troubleshooting, repair, and replacement, etc. This ensures the smooth operation of the customer’s production.

Deepen the partnership: Factory door suppliers and Philippine factories can establish a long-term and stable relationship, through technological innovation, product optimization and other ways to deepen cooperation, and jointly promote industrial development.

Establish trust and cooperation: Moreover, factory door suppliers must earn the trust and recognition of Philippine factories by delivering high-quality products and services. This is essential to establish a long-term and stable cooperative relationship.

Successful Case Study

Success Story: Jentec Storage Inc’s Factory Door Application

Background: Jentec Storage Inc. specializes in logistics, warehousing and distribution with a network of cold chain facilities. Additionally, catering to the food and manufacturing industries, the company prioritizes efficiency, health, safety, and environmental concerns as its service objectives. Established in 2007, Jentec Storage Inc has chosen high-speed roll-up and sectional doors as the primary entrance/exit facility to ensure production efficiency and product quality.

Why choose us?

QUALITY ASSURANCE: Our factory doors are manufactured with advanced technology and high quality materials under strict quality control to ensure durability and reliability. Our main products include rapid roller shutter doors, turbo rigid rapid doors, industrial lift doors, garage doors, insulated rapid doors and so on. SEPPES brand is chosen by 1 out of every 7 Fortune 500 companies. Exporting to more than 50 countries overseas, the quality of our products is recognized.

Customized service: We are able to customize various types of factory doors according to customers’ needs, meet the special requirements of different factories and provide personalized solutions.

Technical support: Furthermore, we boast a professional technical team and dedicated after-sales service team. Their primary goal is to offer customers comprehensive technical support and after-sales assistance, ensuring the protection of the customer’s experience.

Communication process with customers

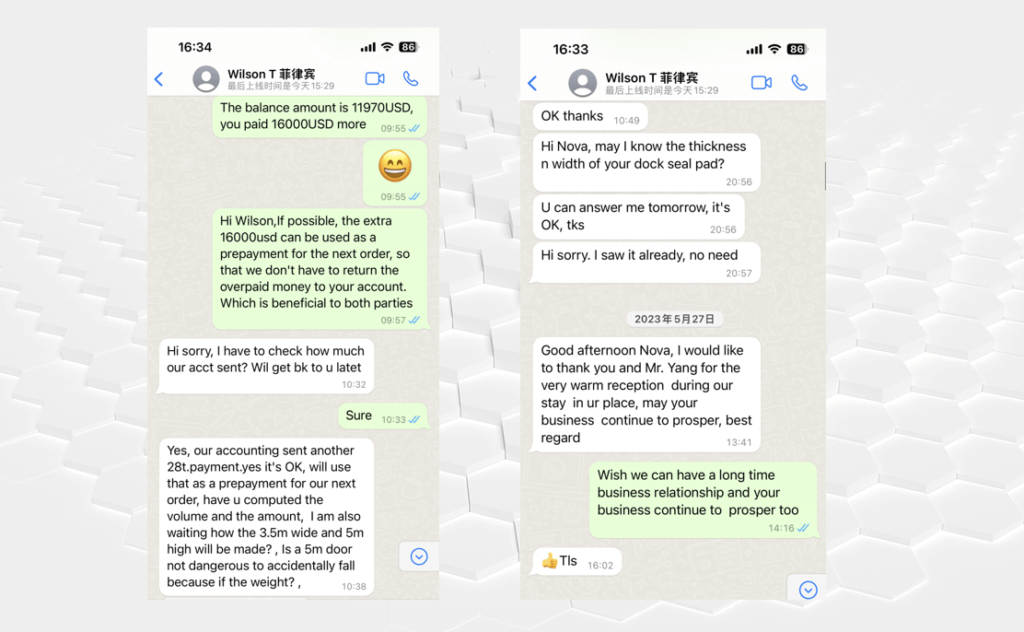

1. The customer pays 16000USD more than the final payment.

(11.2 W RMB) as prepayment for the next order.

2.The customer affirms the cooperation between both parties.

Key Factors

Technologically advanced product selection: Jentec Storage Inc chose a high-speed roll-up door that opens and closes very quickly and quickly returns to a closed state, making it suitable for high-frequency use. This technologically advanced product choice effectively improves productivity and process operations.

Adaptive Design and Material Selection: Jentec Storage Inc’s factory doors are waterproof, dustproof, and windproof, adapting to the changing climatic and environmental conditions of the Philippines region to safeguard production equipment and products.

Regular Maintenance and Repair: Jentec Storage Inc emphasizes regular maintenance and repair of factory doors to ensure proper operation and longevity. This practice reduces equipment failures and downtime and ensures production continuity.

Close Collaboration with Suppliers: Jentec Storage Inc maintains a close working relationship with its factory door suppliers. Communicating and resolving issues in a timely manner and discussing solutions to ensure the quality and performance of the factory doors.

Safety Awareness and Training: At XJentec Storage Inc, we prioritize the development of safety awareness and employee training. Therefore, we regularly organize safety education and training activities. This ensures that our employees are equipped with the necessary skills to operate factory doors correctly, thereby reducing the risk of accidents.

Lessons Learned

Importance of regular maintenance and upkeep: As an important facility in industrial production. Factory doors require regular maintenance and upkeep to ensure stable operation and longevity of the equipment.

Selection of suitable products and materials: When choosing factory doors, you need to select suitable products and materials according to the actual needs of the factory and environmental conditions to ensure product quality and safety.

Establish a good relationship with suppliers: Establishing a good relationship with suppliers of factory doors enables timely communication and problem solving, and jointly improves product quality and service level.

In our past collaborations, we have been deeply honored to cultivate a long-term and stable relationship with our customers in the Philippines. Moving forward, we sincerely aspire to see this bond grow even stronger, as we mutually witness each other’s development and growth. With this in mind, may the door of our cooperation always remain open, paving the way for a brighter future together!

Looking at the trends and prospects of factory doors in the future development of Philippine industry

Conclusion

Importance of Factory Doors: As an indispensable and important part of industrial production. Factory doors play a key role in improving production efficiency, ensuring a safe environment and promoting industrial modernization.

Importance of partnership: Moreover, a strong partnership between factory door suppliers and Philippine factories can enhance product quality and service levels. This collaboration can also inject new impetus into industrial development.

Technological innovation and customized services: Furthermore, technological innovation and customized services are crucial factors for the success of factory doors in the Philippine industry. These elements enable companies to meet the individual needs of customers and enhance product competitiveness.

Outlook

Application of Intelligent Technology: With the continuous development of intelligent technology. Factory doors will be more intelligent in the future, such as intelligent sensing, remote monitoring and so on, to enhance the intelligent level of industrial production.

The trend of green environmental protection: With the improvement of global environmental protection awareness. The factory door in the future will pay more attention to green environmental protection. Such as energy saving and emission reduction, environmentally friendly materials, etc., to promote the sustainable development of industry.

The development of digital management: factory door suppliers and factories in the Philippines will be more inclined to digital management. Such as supply chain management, data analysis, etc., to improve the efficiency and effectiveness of cooperation.

Industrial upgrading and transformation: With the economic development and industrial upgrading. Factory doors will pay more attention to technological innovation and quality improvement in the future. Injecting new impetus and vitality for the development of Philippine industry.

In summary, factory doors, as an important part of industrial production. Will play an increasingly important role in the future industrial development of the Philippines. With the progress of technology and market demand, factory doors will continue to iterate and update. Providing solid support for the progress and development of Philippine industry.